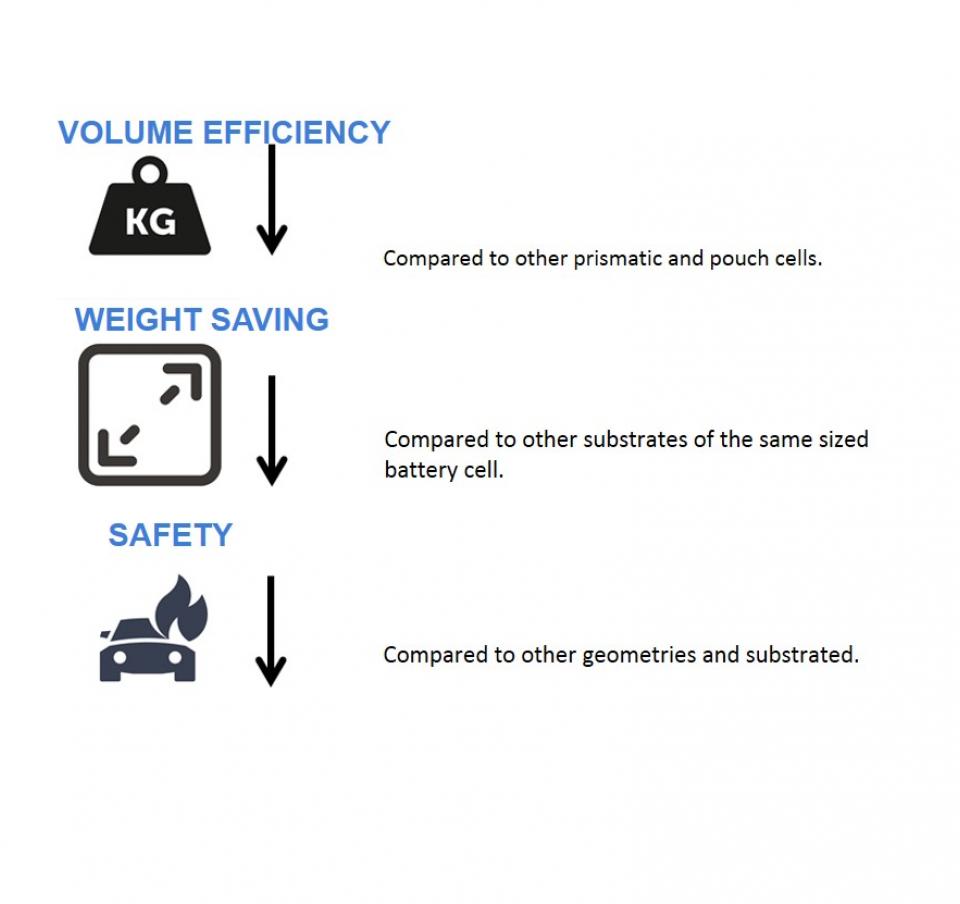

HILUMIN for cylindrical battery cans enables higher energy density and more volume efficient battery packs

Battery cans made of HILUMIN provide the highest internal volume whilst offering the best thermal stability compared to other substrates. In addition, cells made from HILUMIN can withstand higher pressures than pouch and prismatic cells.

HILUMIN® is an electro nickel-plated diffusion annealed steel strip for battery applications where low contact resistance and high corrosion resistance is required

Manufactured using an ultra-clean steel grade, it plays an integral part in the production of batteries. HILUMIN offers outstanding performance features. The consistent and reliable quality of this product also ensures trouble-free processing in high-volume, high-speed operations.

Tata Steel is the world's leading supplier of materials for the production of battery casings. It is used for decades in the Alkaline industry, but also in the rechargeable industry for e.g. aerospace applications. Its outstanding properties enabled the supply chain to move to high-speed processing and improved the efficiency of the whole supply chain. Tata Steel -Plating- continuously optimises Hilumin together with its customers to reduce the TCO based on customer specific requirements.

Superior performance

HILUMIN is produced from ultra-clean, specially-cast steel. Our proven and dedicated plating and heat treatment process ensures high corrosion resistance for long battery life. The consistent quality of HILUMIN also meets the demands of high volume, high speed battery component production. HILUMIN is custom-made for each application and is available for any battery type (alkaline, lithium, NiMH, NiCd and Li-Ion, Zn Air). It is also available as perforated steel strip. HILUMIN comes in a wide variety of finishes and offers:

- outstanding formability (with excellent adhesion) for high-speed can-making and cell assembly

- excellent corrosion resistance and low contact resistance

- excellent deep drawing capability

- consistent mechanical properties and tight tolerances

- low earing characteristics

For automotive downloads such as brochures, case studies and data sheets, please click below: