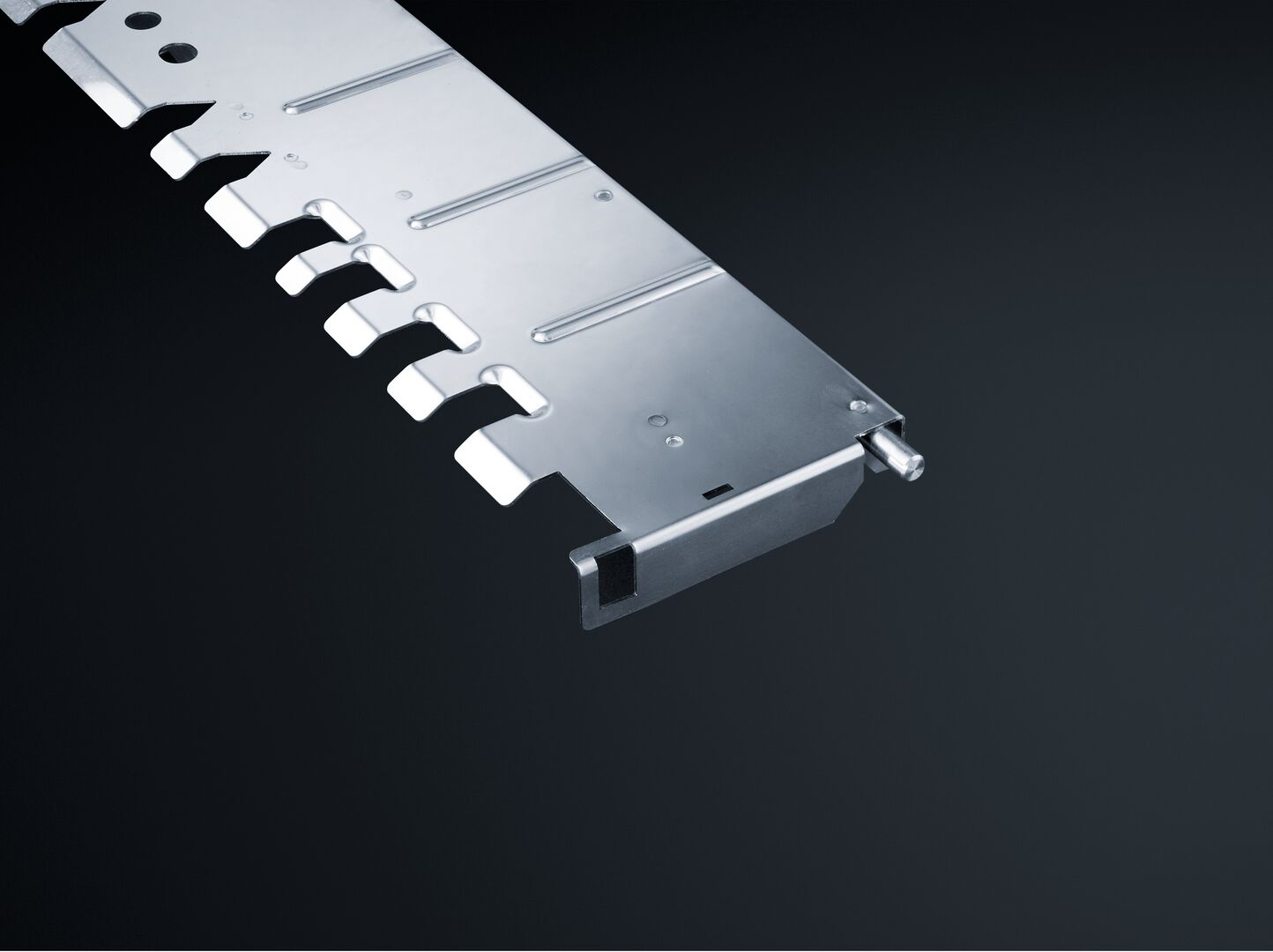

Nickel-plated steel applications include electronic components, automotive components, battery components, telecommunications equipment, ICT products and office equipment.

Quality products

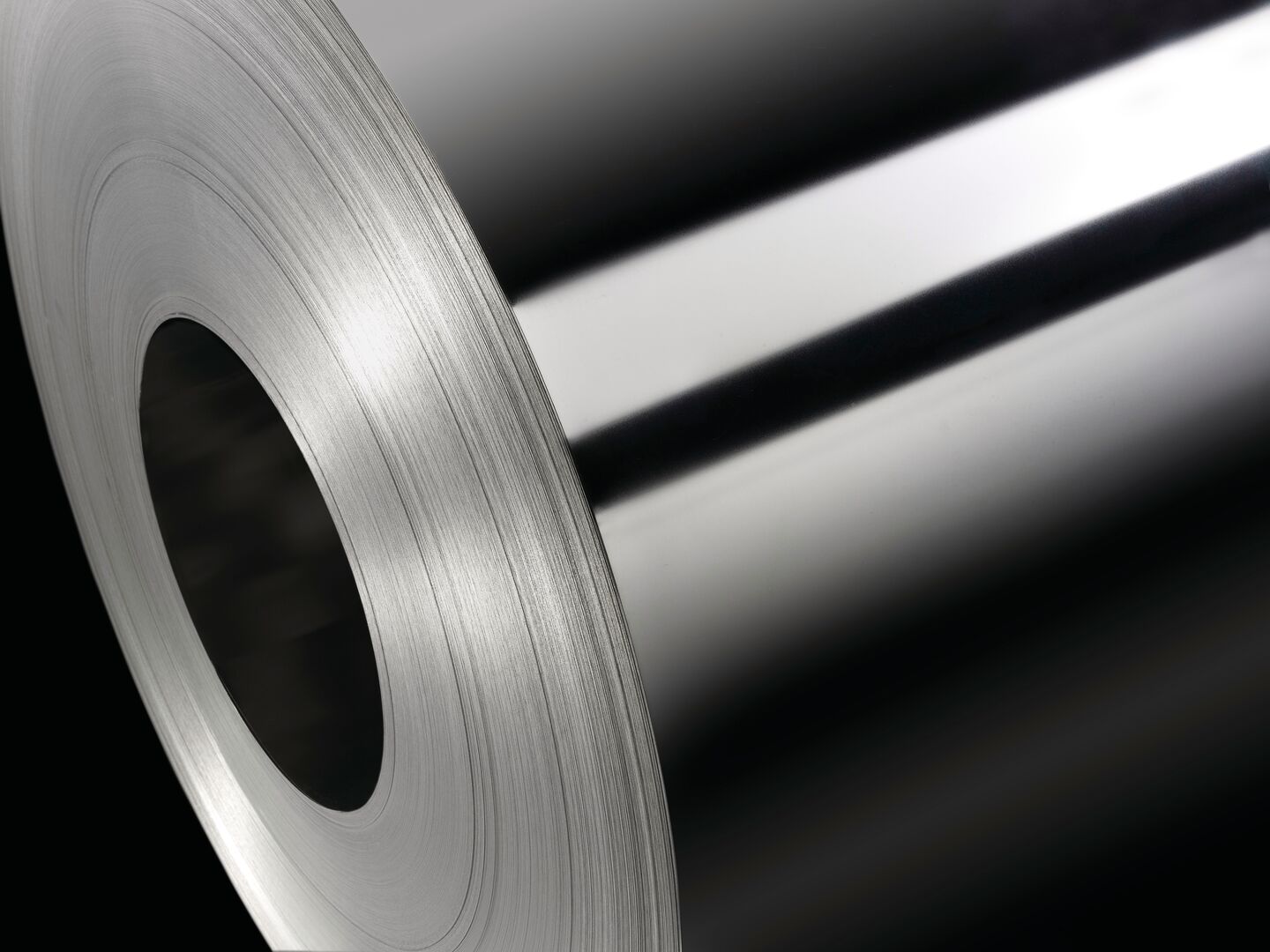

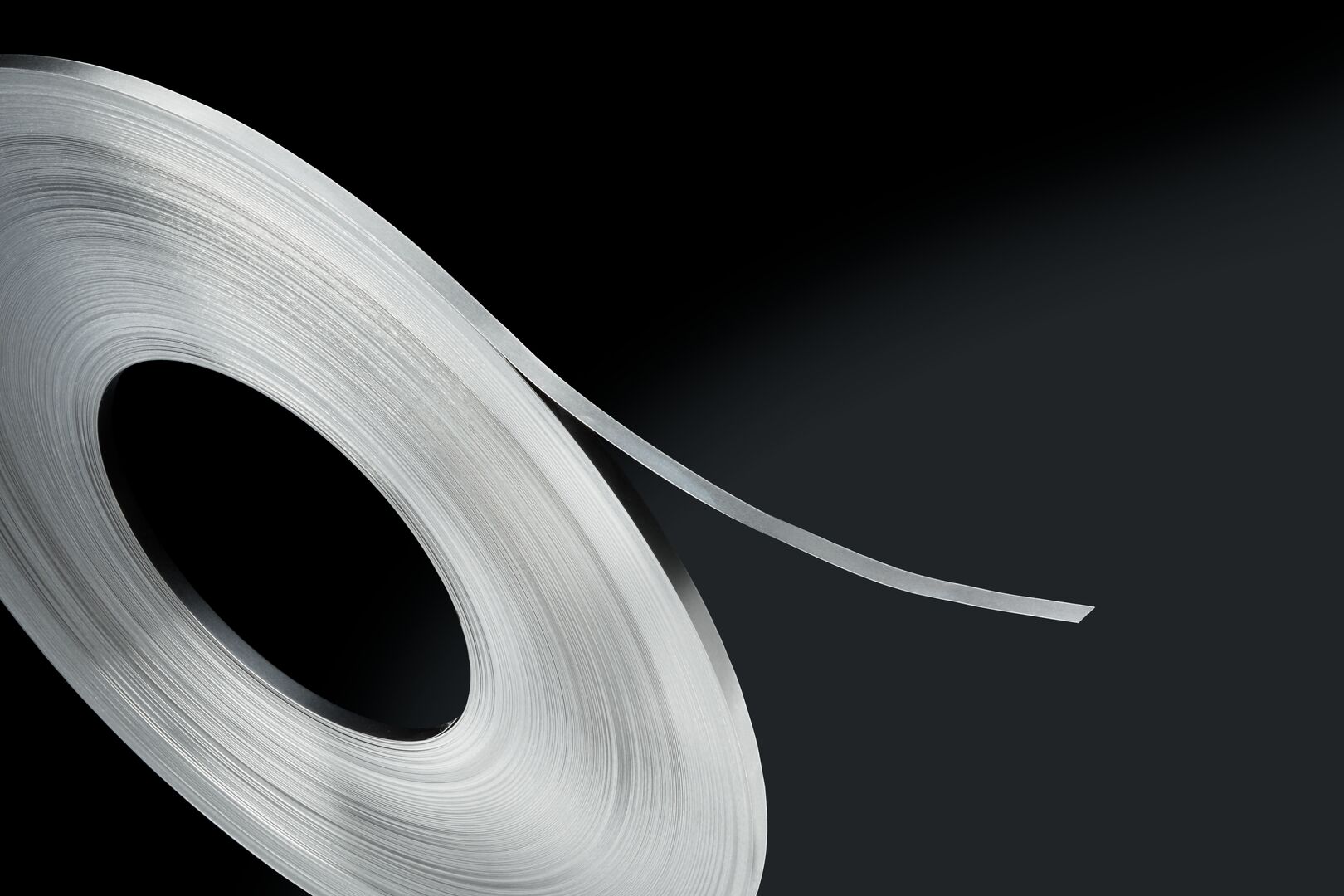

Tata Steel produces two cold-rolled, nickel-plated and heat-treated steel strip products - NICOR® and HILUMIN®. To ensure a good basis for your end-product quality, our cold-rolled steel sheet is produced only from high-grade hot-rolled steel strip. Our optimised rolling and finishing technologies mean we achieve extremely tight dimensional tolerances and perfect, homogeneous consistency of the nickel layers. NICOR and HILUMIN provide an excellent basis for further processing. They also give you semi-finished, electro nickel-plated end-products of superior quality.

Functional, efficient and cost-effective

NICOR and HILUMIN are designed to make further processing more efficient and cost-effective. Cold rolling, electroplating with nickel and diffusion annealing provide excellent deep drawing capability and corrosion resistance. The consistent quality of these products means you can rely on them to perform time and again. NICOR and HILUMIN offer:

- inseparable bonding between nickel layer and steel substrate

- temperature resistance to over 200°C

- tight tolerances and optimal consistency of layer thickness

- improved corrosion resistance because of diffusion annealing

- extra deep drawing capability

- good scratch and abrasion resistance

- very good further processing characteristics (weldable, brazeable)

- excellent resistance against aggressive fuels such as bio diesel

The heat treatment ensures an inseparable bond between the homogeneous nickel layer and the steel substrate. This delivers benefits in further processing. It also means you can rely on NICOR for semi-finished end-products of superior quality.

Reliable performance

Tata Steel Plating has proven expertise in the production of nickel-plated diffusion annealed steel and other electro plated steel products. The cold-rolled steel sheet that forms the basis of NICOR is produced from top quality hot-rolled strip. Rigorous control of our cold rolling, electroplating and diffusion annealing processes means that NICOR offers:

- excellent corrosion resistance

- temperature resistance to over 200°C

- tight tolerances and optimal consistency of layer thickness

- improved corrosion resistance

- extra deep drawing capability

- good scratch and abrasion resistance

- very good further processing characteristics (weldable, brazeable)

- excellent resistance against aggressive fuels such as bio diesel

Main benefits of NICOR include:

- improved end-product functionality

- end-products of consistent and reliable quality

- trouble-free, repeatable processing

- scope to optimise processes

- minimised yield loss

EN-Plating-Datasheet-Nicor

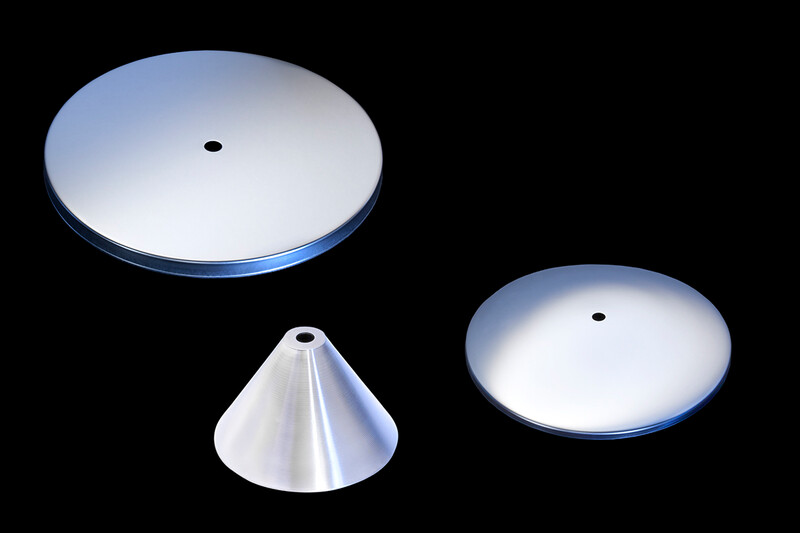

Battery cans demand a very special plated steel product to ensure the best performance, corrosion resistance, non-leakage and deep drawing capabilities. HILUMIN meets these needs through a combination of ultra clean specially-cast steel and a dedicated plating and heat treatment process. HILUMIN is:

- available for any type of battery (alkaline, NiMH, Nid and Li-Ion)

- custom-made for each individual application

- available for connector strips or as perforated steel strip

- available in a wide variety of finishes

For an even more advanced coating performance, HILUMIN Cobalt has an additional cobalt plating as a top coating. HILUMIN Cobalt outperforms the traditional alkaline battery can by enhancing the age performance considerably.

HILUMIN offers:

- outstanding formability for high-speed can-making and cell assembly

- excellent corrosion resistance and low contact resistance

- high product reproducibility and tight tolerances

- low earing characteristics for minimised scrap rates

EN-Plating-Datasheet-Hilumin

The bright nickel-plating creates an extra hard and extra bright surface with superb strength. When you need a great looking finish for a visible surface, HILAN provides the answer at a competitive price. HILAN is ideally suited for decorative applications. You can also utilise HILAN for stamping and deep drawing.

Main benefits of HILAN include:

- end-products of consistent and reliable quality

- improved end-product performance

- trouble-free, repeatable processing

- opportunities to reduce processing steps

- longer tool life

- opportunities for cost savings

EN-Plating-Contact-Hille and Muller general

General enquiries

Tata Steel Plating

Head Office

c/o Hille & Müller GmbH

Am Trippelsberg 48

D-40589 Düsseldorf