Tata Steel partnered with road transport trailer manufacturer BERGERecotrail® to substantially increase the carrying capacity of the customer’s products, while radically reducing fuel consumption and carbon emissions. As a result BERGERecotrail expects a significant rise in demand over coming years – growth that Tata Steel is well placed to support.

The challenge

Commercial and regulatory pressures mean the road haulage industry is increasingly committed to cutting fuel costs and the environmental impact of freight transport. The manufacture of lightweight semi-trailers is a commercially beneficial solution to this pressing issue.

The solution

A ten-year relationship with BERGERecotrail enabled Tata Steel to supply the customer with the Ympress® S700MC product. As a result, BERGERecotrail is marketing technically advanced products, while making a valuable contribution to Europe’s low carbon economy.

The product

The strength and outstanding formability of Ympress S700MC means BERGERecotrail can design its components with lower wall thickness, while guaranteeing the required stability and safety.

EN-Engineering-Casestudy-Ympress BERGERecotrail

Ympress S700MC: BERGERecotrail - Case study

Fewer journeys needed

Ympress® S700MC steel ensures ultra-low unladen weight, for seven per cent fewer journeys.

Fuel consumption reduced

Fuel consumption significantly reduced due to trailer’s own unladen weight.

Cost saving benefits

6.1% cost saving from fewer journeys and lower fuel consumption.

Fuel saving potential

54 million litres of fuel could be saved in Germany alone if 50% of semi-trailers were payload optimised.

Payload optimisation – improving the carrying capacity of a vehicle – is the most urgent and demanding issue facing the freight transport sector.

The goals of payload optimisation are to:

- Increase the amount of freight that can be transported per tractor-trailer

- Raise vehicle payload to reduce the weight of tractors and semi-trailers

- Develop lightweight semi-trailer construction – vital in a competitive and environmentally sensitive market

Innovation is the key to market leadership

BERGERecotrail® is regarded as the benchmark business in the design and production of semi-trailers. Tata Steel’s role was to help the customer maintain its market-leading position by continuing to innovate leading-edge products.

Having supplied BERGERecotrail with all sheet products for more than ten years, Tata Steel identified its Ympress® S700MC product as ideal material for the customer’s lightweight and payload-optimised semi-trailers.

High performance steel to create top quality semi-trailers

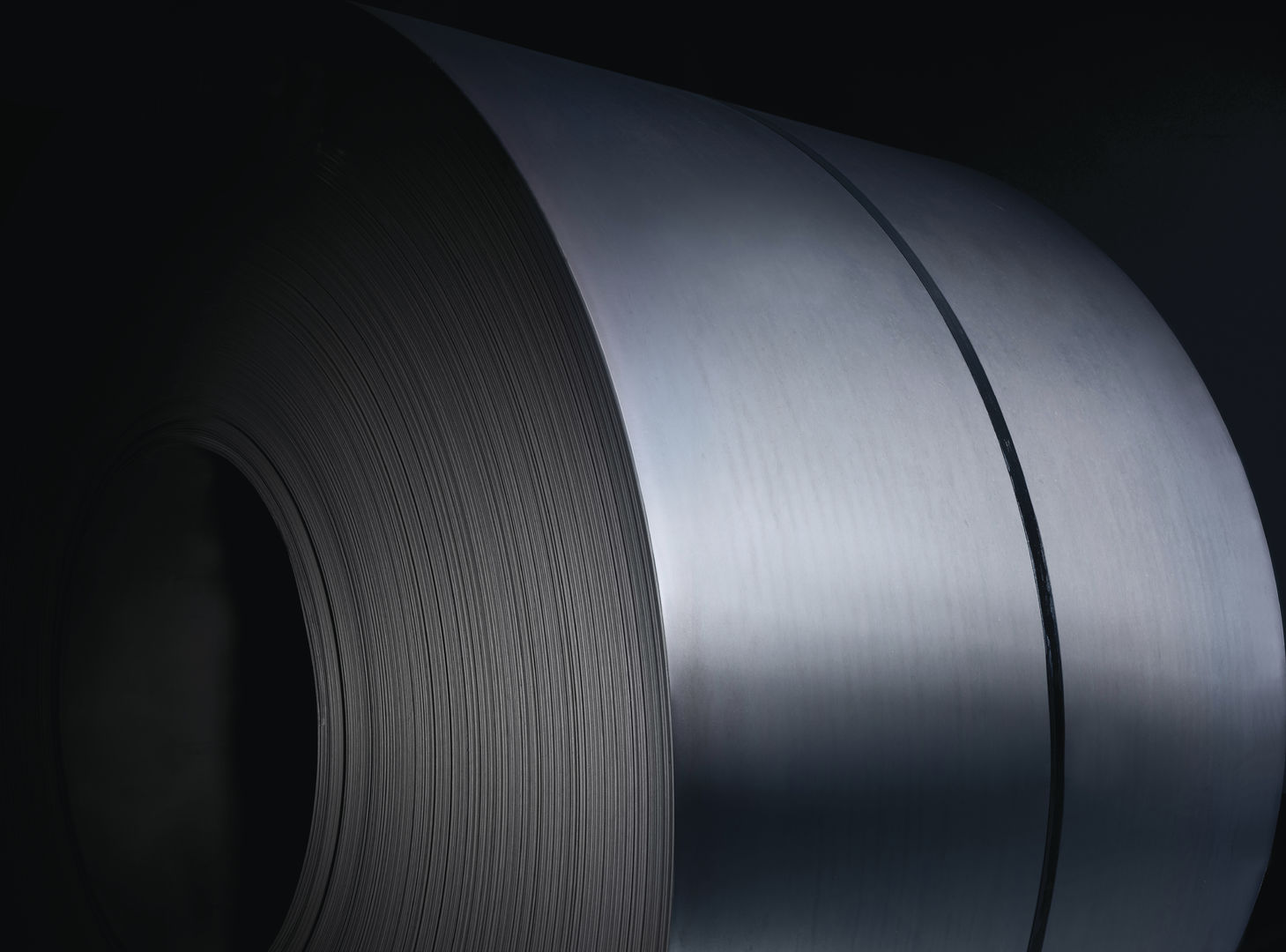

The Ympress product range consists of hot-rolled, high-strength and low-alloy steels notable for their outstanding formability. Moreover, product characteristics – such as mechanical properties, steel chemistry and the tightest dimensional tolerances – remain consistent.

The high strength and outstanding formability of Ympress S700MC would enable BERGERecotrail to:

- Design components with lower wall thickness

- Guarantee required stability and safety

- Build semi-trailers with an extremely low unladen weight – less than 4.7 tonnes

- Demonstrate very high fatigue strength

An extra benefit is that BERGERecotrail could use Ympress S700MC to produce a design containing only hollow, U and Z profiles. This would stop water leaking into the structure and – by painting all exposed parts – deliver an excellent corrosion protection.

Using Ympress® S700MC to manufacture BERGERecotrail® semi-trailer bodies and welded-frames for the chassis delivers a number of benefits, including:

- More goods transported per journey

- Average journey numbers reduced by 7%

- A marked reduction in fuel consumption on journeys with lower loads

- Overall cost savings of 6.1% on average

Versatility of fine-grained steel delivers major benefits

Tata Steel also handles the entire management of the supply chain for the production and delivery of a number of different gauges of Ympress S700MC. Our Service Centre Maastricht (Feijen) manages:

- Production of the Ympress S700MC coils and de-coiling

- Needs-based stock holding and transport logistics

- Just-in-time delivery

- Transport of completed parts to the customer’s trailer production plant in Austria

Development of payload-optimisation pays dividends

One particular highlight in the design of the payload-optimised semi-trailer is the two longitudinal beams. The 13.6-metre long components are designed to be very slender and feature cut-outs in the shape of Reuleaux triangles for further weight savings, combined with a high degree of stiffness.

The laser cutting of the webbing is handled by a qualified supplier. Tata Steel functions as an intermediary between BERGERecotrail and the laser facility to ensure the material is completely satisfactory.