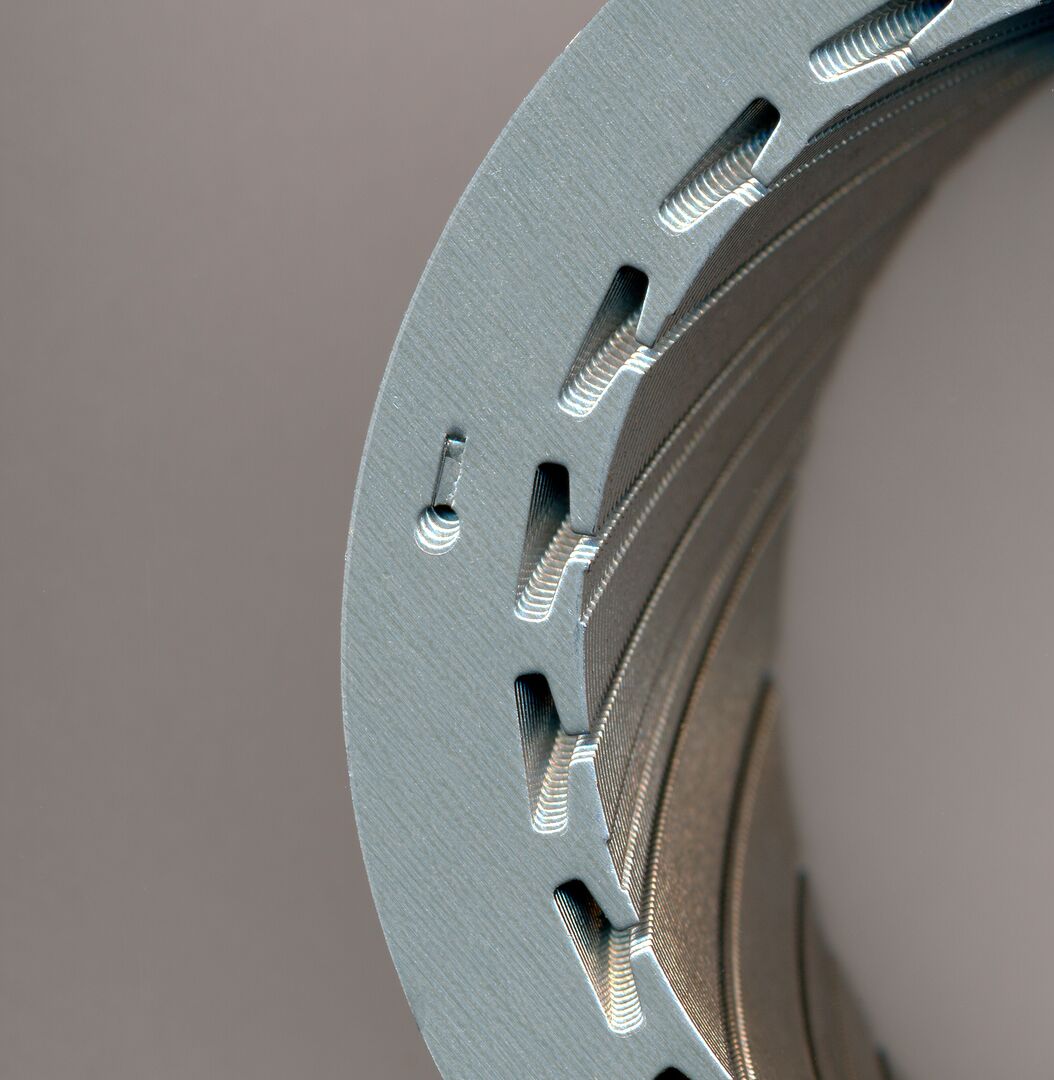

Reliable, highly efficient and powerful motors

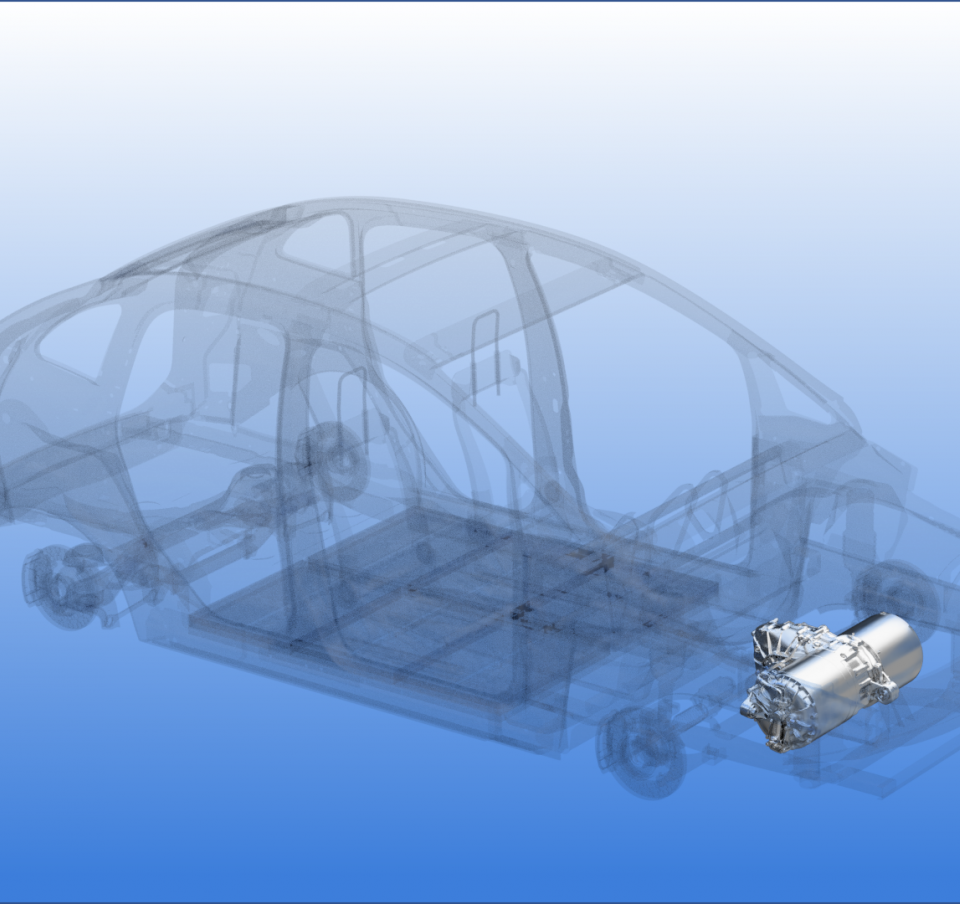

Continuous improvement often forms the basis of successful technology. It’s the same for electric motors in automotive applications. Even as the first surge of electric vehicles is entering the market, engineers are already designing the next generation of electric motors to be more sustainable, more efficient and to perform better. The application of next generation non-oriented electrical steels in electric motors, with further optimised designs, is key to achieving these goals. Partnerships between material suppliers, stampers and e-motor designers can make a difference.

Electrical steel for next generation designs

Today’s electric motors in automotive are always designed for a specific application. Different material requirements will arise depending on the chosen technology and motor design. The requirements will vary in permeability, magnetic losses and yield strength, among others. The material’s gauge is also important, not only to meet performance but for processing requirements. This wide range of options requires electrical steels to be versatile, which is exactly what our Hi-Lite product range of non-oriented electrical steels aims for. Hi-Lite opens up a world of possibilities when designing high frequency applications. It helps you achieve harmony between size, weight, energy efficiency and performance.

Making your product better

Our main focus is finding the solutions that will improve your product. We have a wide variety of versatile thin gauge electrical steel with unprecedented material characteristics. We also have years of experience in material science and application design. Choose Hi-Lite to tap into a new way of working, and gain immediate access to the “best of the best” in materials science, design, tooling and stamping.

We can offer expert knowledge and readily available sample material to enable design iterations to be made efficiently and effectively. Backed by the multiple skills of our international network, we’ll help transform your innovative visions into commercial reality.

Please contact us to find out how we can support you.

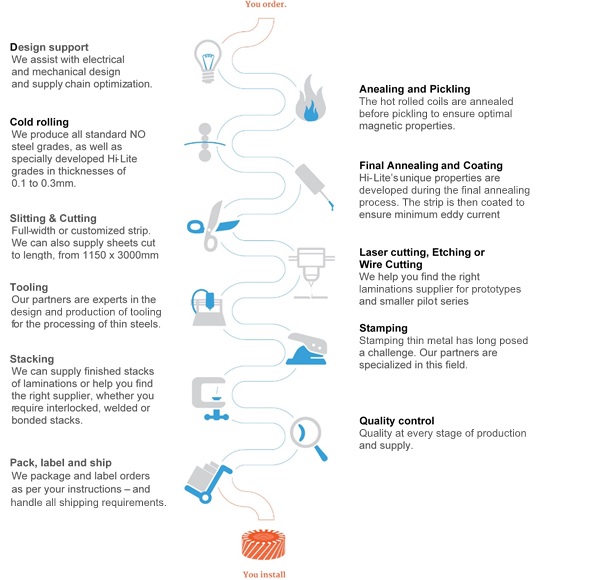

Supporting you every step of the way

Working with thin materials can be challenging. Achieving industrial volumes in a given timespan is never certain. Make life easy for yourself. Less stress, more cost efficiency. Contact Tata Steel's team of dedicated experts. Backed by the multiple skills of our international network, we’ll help transform your innovative visions into commercial reality. We can even help set up pilot units prior to you establishing your own production facilities. From single elements to the design, manufacture and supply of complete components, the choice is yours.

The whole process is available to you: it’s your choice.