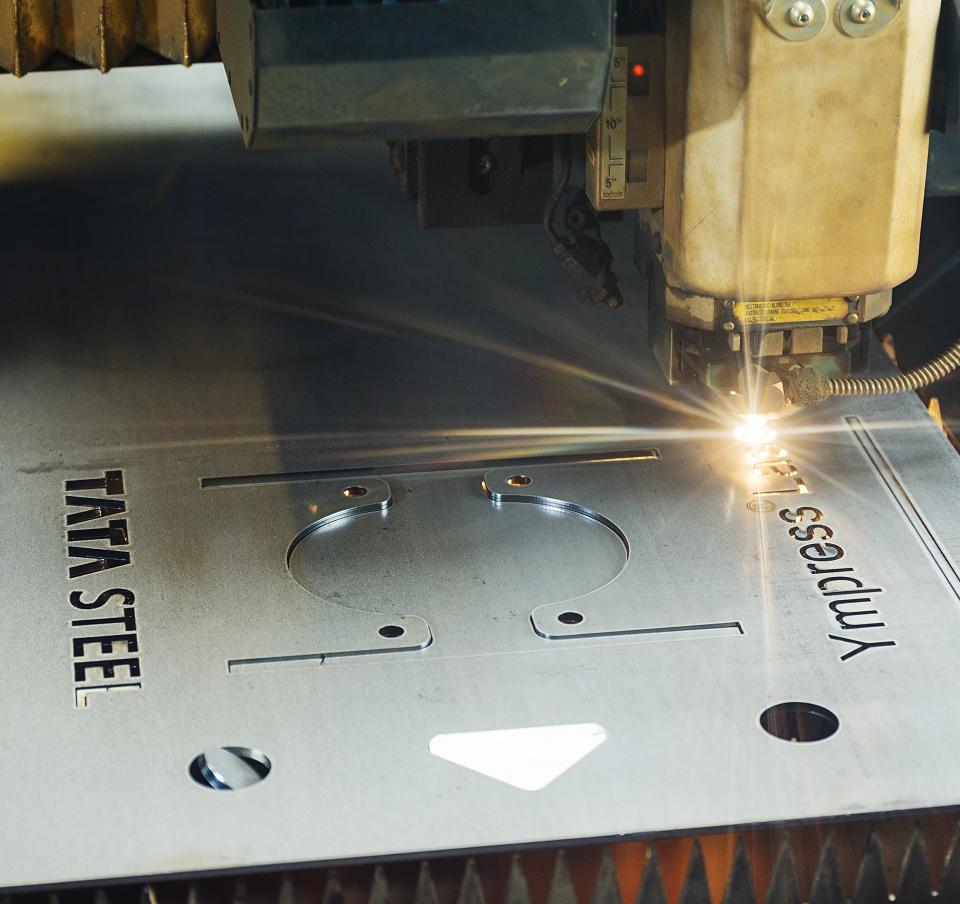

Ympress® Laser offers fast, efficient laser-cutting with superior performance

Specially prepared to enable fast cutting with a clean-cut edge, it is ideal for automated processing and guarantees production efficiency and consistency. Ympress Laser is tailor-made for efficient, high-speed laser cutting. This homogeneous, hot-rolled steel combines exceptional flatness with an excellent surface. It delivers improved end-product quality and trouble-free laser cutting for improved productivity and yield.

Manufactured and supplied to consistently high standards, Ympress Laser products are available from stock via approved distributors and backed by expert technical support.

Get in touch with us to discuss how Ympress Laser can support your needs.

The sheet-to-sheet consistency of Ympress Laser makes it ideal for unmanned cutting machines

It can be delivered to you fast through our dedicated supply chain which operates to stringent, audited service level standards.

The benefits of Ympress Laser include:

- Increased productivity

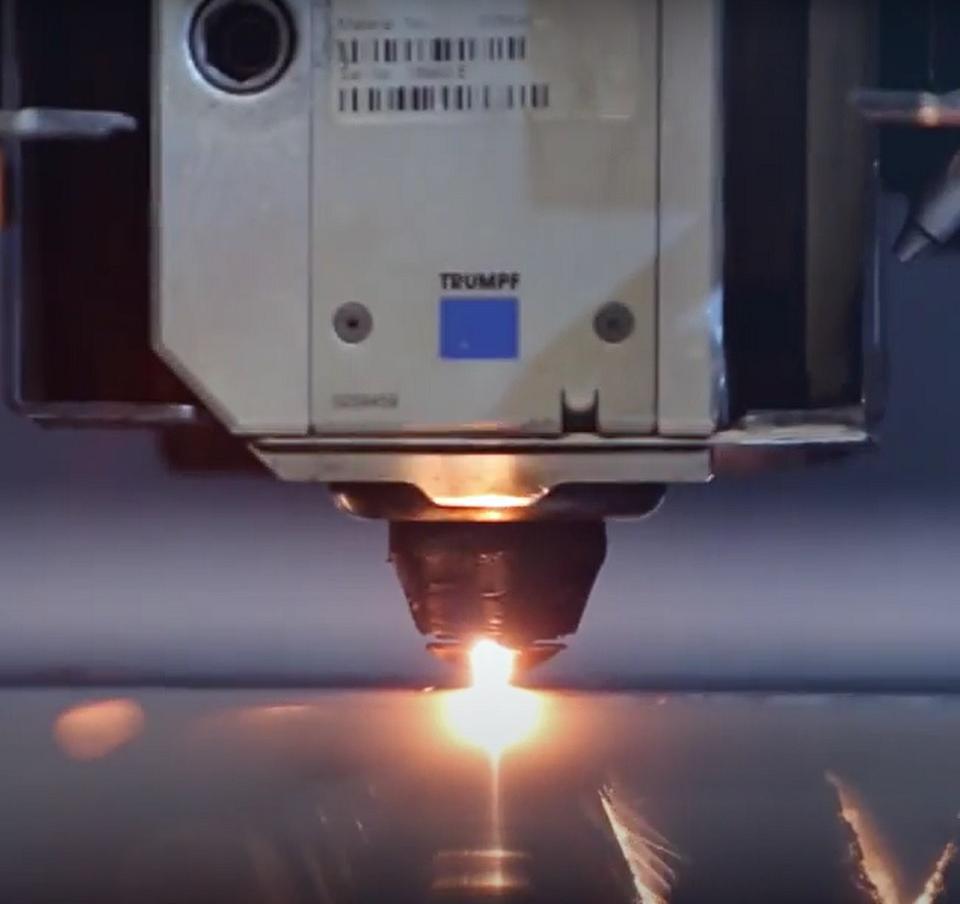

Reliable quality including a consistent oxide layer allows faster, continuous cutting with reduced set-up time and minimal operator intervention

- Improved part yield

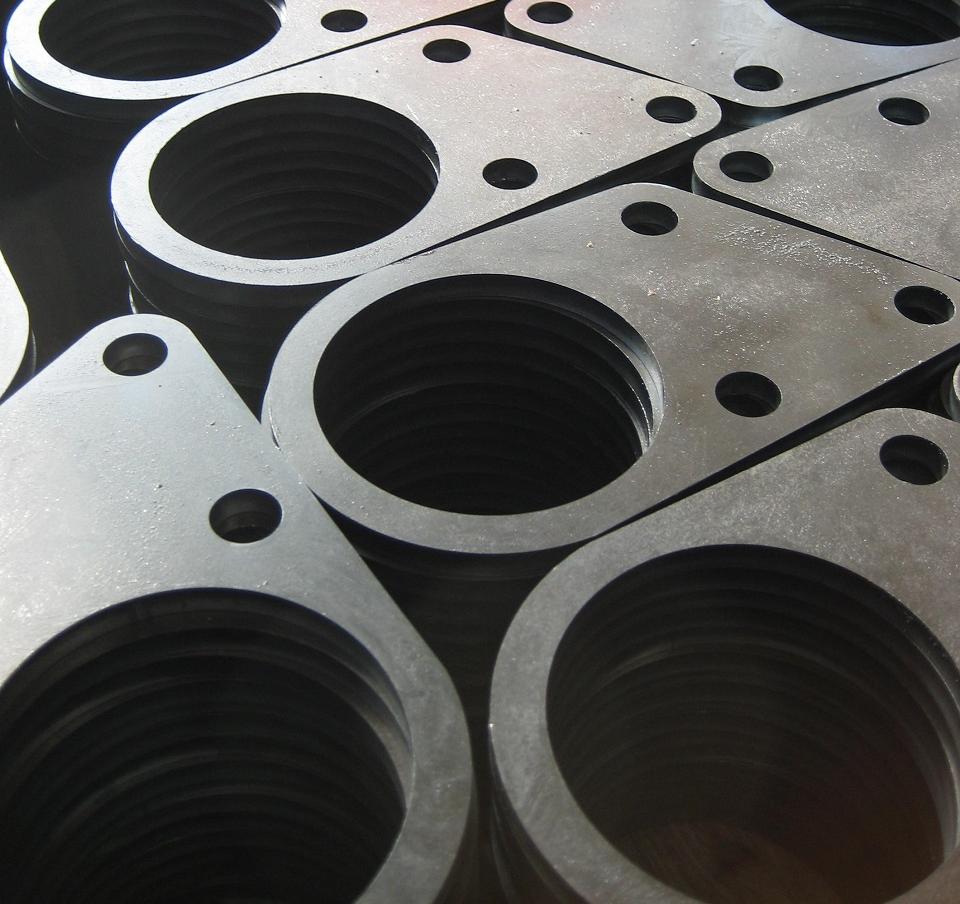

Flexible part nesting, more conforming parts and reliable extraction combine to boost yield

- Better end products

Ympress Laser delivers reliable flatness, surface and cut edge quality for improved product quality

- Reliability of supply

Available from stock through our dedicated supply chain - in standardised, recyclable packaging for product protection and brand recognition

- Proactive technical support

Our technical experts are always ready to assist you – helping you to optimise and maintain laser cutting efficiency

Manufactured with precision, Ympress Laser steels are ultra flat and ideal for part nesting

Stringent control of our manufacturing process and our controlled supply chain with approved processors and distributors means you can rely on Ympress Laser to perform.

The process offers:

- refined chemical composition with tighter tolerances

- enhanced process control at hot strip mill to provide a well-adhered oxide layer

- controlled storage to keep our steel in prime condition

The product offers:

- minimal residual stress for a flatness variation of no more than 3mm per metre in cut parts

- high levels of homogeneity for excellent surface and cut edge quality

- a dross-free surface after cutting for easy part extraction

Get in touch today to see how Ympress Laser can support your needs.

For Engineering downloads such as brochures, case studies and data sheets, please click below: