Tubes for the next generation of transportation equipment

Tata Steel in Europe produces high-strength precision tubes for chassis and suspension applications. Our tubes excel in surface quality, fatigue performance and formability. Furthermore we can offer the following additional capabilities:

- Normalising

- Cut-to-length

- Bevelling

- Notching of tube ends

We can support you in the engineering phase with our R&D and processing expertise.

Tata Steel offers various specialised tube solutions for manufacturers of trucks and trailers in precision (EN 10305) and cold formed (EN 10219).

Our high-strength steel tubes made out of strip S700MC (EN 10149-2) are used by manufacturers to comply to the latest Run Under Protection Device (RUPD) legislations and helps save lives by withstanding high-impact forces in case of a collision.

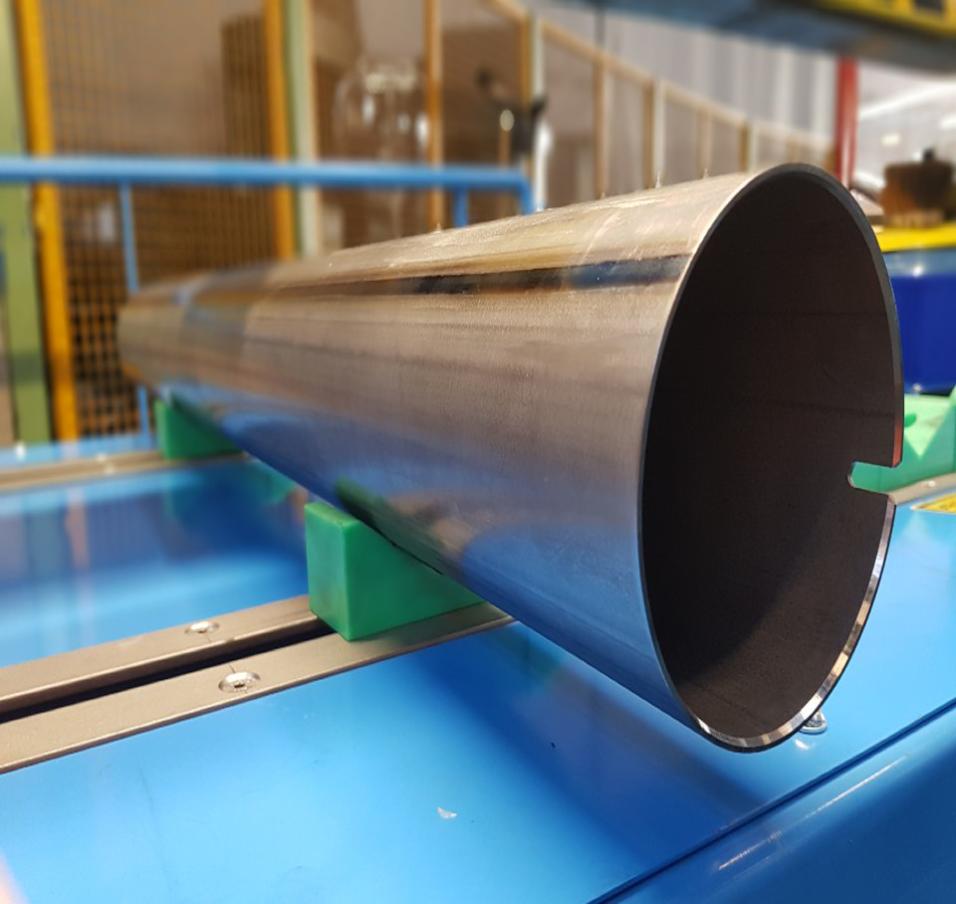

Using our capability to deliver tight tolerance tubes, we deliver telescopic tubes to manufacturers of landing gears for trailers. For truck/bus propeller shafts we supply tubes with special Mn/Si content to meet the fatigue performance requirements, as was shown in extensive fatigue studies performed on this application.

For transportation equipment we offer a full range of tube solutions, as can be viewed below and we understand other key requirements for our customers:

- Our supply solutions ensure you have your material when you need it

- Our technical team is there to support you in optimising your production

- Our Advanced Engineering team can help you to incorporate the best steel solutions into your current and future vehicle designs.

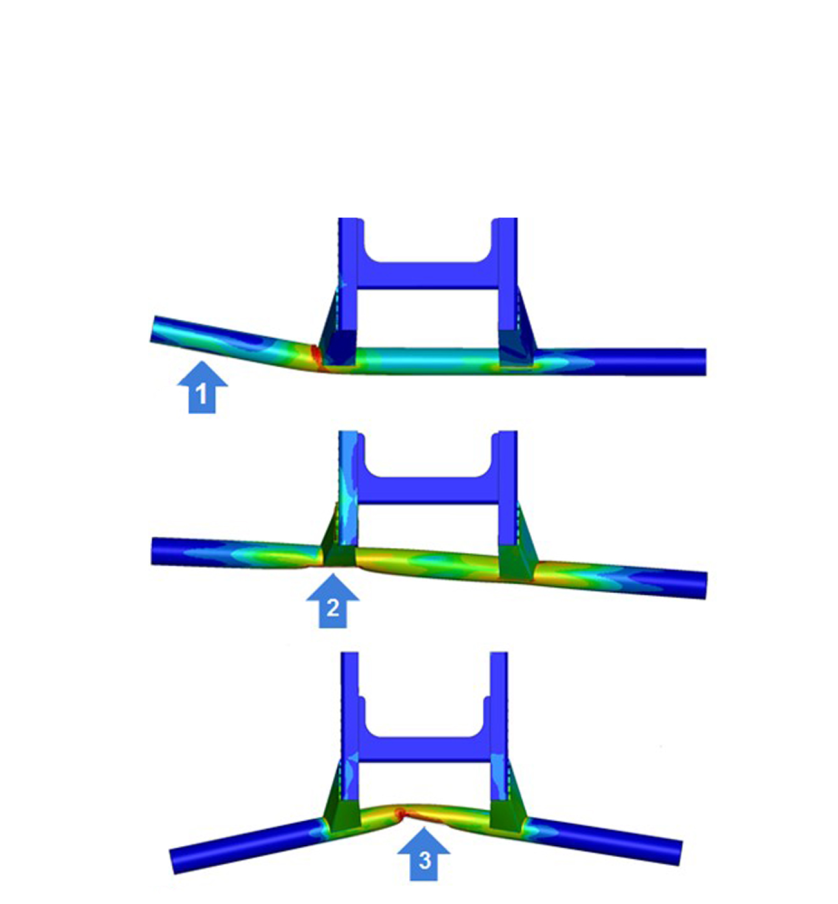

Run Under Protection Device

In the event of a rear-end collision the Run Under Protection Device prevents smaller vehicles from becoming lodged underneath the truck or trailer. The EU has introduced stricter regulations to improve safety of upcoming vehicles in case of a collusion, Tata Steel's Tubes supplies semi-finished product (precision tube) to truck and trailer OEM’s in a EN 10305-3 E700 or EN 10219-3 S700MH grade to fulfil the EU Norm ECE R58-3.

This high-strength steel is designed to withstand the impact of a collision. Typical dimensions are:

- Typical dimensions are: Ø120/121 x 3.5 up to 5 mm (OD x WT)

- 120x120 x 4 up to 6 mm (H x B x WT)

Different grades and/or dimensions are available. Available in fix lengths.

Tata Steel has detailed insight into the new ECE R58-3 legislation and is experienced in providing support to optimise the design of your RUPD. Together we can improve road safety for by using better Run Under Protection systems.

Our Advanced Engineering simulations provide valuable insights on which grade and dimension is suitable for your RUPD.

Telescopic Landing Gear

In our product portfolio we have several sizes/grades available for telescopic landing gears. Mainly these tubes are produced with tight tolerance according our Hybox TT specification:

- Several grades and /or dimensions are available

- Available in fix lengths

- Additional testing to ensure quality: weld test

- The tight tolerances of our Hybox TT make the product highly suitable for automatic processing like stamping and robot welding

Connection crossmember

In our product portfolio we have several sizes/grades available for connection crossmembers between the landing gears. Mainly these tubes are special products with tight tolerance according our Hybox TT specification:

- Several grades and /or dimensions are available

- Available in fix lengths

- Additional testing to ensure quality: weld test

Other tubular products available for trucks and trailers

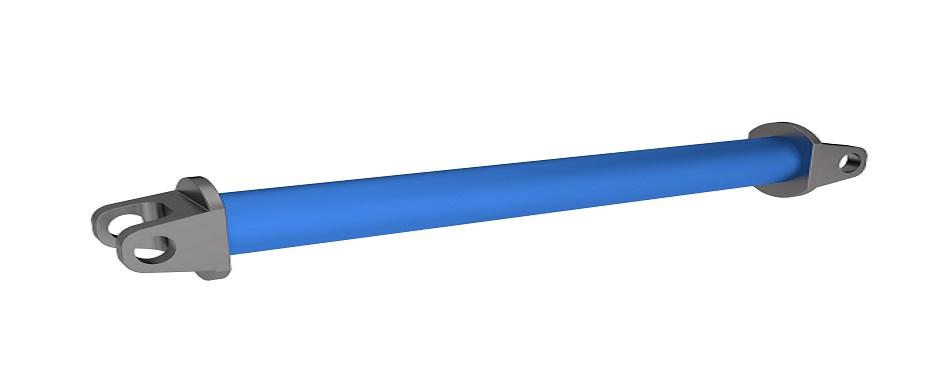

HFI welded precision tubes are used to manufacture propeller shafts for Automotive applications mostly for truck and busses.

Tata Steel feedstock consist of a favourable Si/Mn ratio to increase fatigue life of the propeller shaft.

Typical dimensions are (OD x WT):

- ø 89 x 4

- ø 100 x 4.75

- ø 100 x 5.5

- ø 108 x 5.5

- ø 114.3 x 5.5

HFI (High Frequency Induction) welded precision tubes are used to manufacture propeller shafts for automotive applications for truck, busses and other transportation vehicles. Using the Tata Steel R&D facilities and in collaboration with the truck market, Tata Steel'sTubes was able to demonstrate the optimal chemistry to maximise fatigue performance. Please contact for specific range of grades and dimensions available.

Our material experts are there available to support the deployment of our products in your specific application area. For more information contact our transportation tube experts.

READ MORE: HFI-welded tubes versus cold drawn tubes for automotive applications (Article from SCT 2017).

for lateral frame support.

Ø 90 x 3/4/5/6

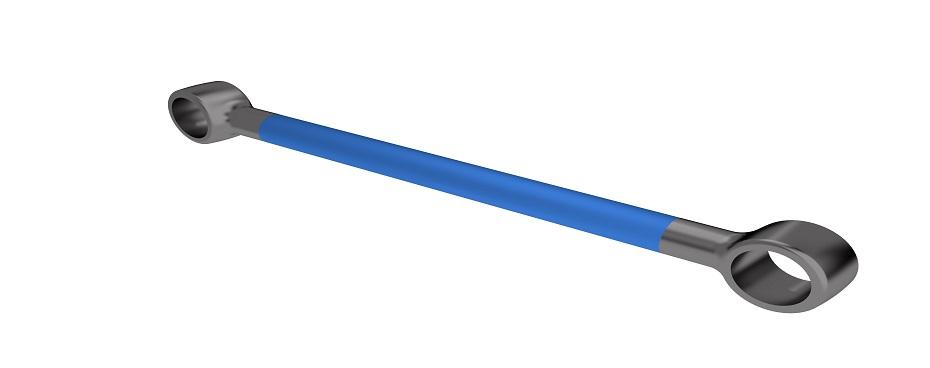

Controls driveline angles of the vehicle, in combination with torque rod.

Ø 52.5 x 4.75

Controls driveline angles of the vehicle, in combination with v-stay.

Specialised treatment (normalised: PJV) to increase fatigue life to avoid accident.

Ø 52 x 3/Ø 52 x 4/Ø 60 x 4

Protected and give structure to passenger compartment.

Connects ARB in a flexible way to the frame.

Part of a steering assembly connecting two parts to pivot.

Designing better performance, safer and more sustainable vehicles

Our Engineering experts have contributed to improving the design of numerous agricultural vehicles. They are open to both offer design advice on how our steel solutions will optimise your equipment towards even tougher, longer lasting vehicles. Our experts also advice on how our steel products will contribute to reducing the CO2 footprint of your vehicles and your manufacturing process.

For more information contact our advanced engineering support team.

Download section

EN-Engineering-Contact-Hans Holtkamp

CTS Tubes

Tubes Maastricht

Tubes Oosterhout

Tubes Zwijndrecht

Please contact us for further information, questions and enquiries.