Lower CO2, seamless integration

European biomethane is a clean, renewable gas that is produced through anaerobic digestion or gasification of organic matter without causing deforestation or competing with food production. As it is chemically identical to natural gas, locally sourced biomethane can be seamlessly fed into the existing gas grid. This process is already underway across Europe, including at Tata Steel Nederland.

Wherever natural gas is used, biomethane can serve as a direct replacement, significantly reducing our CO2e footprint. Unlike burning natural gas, which releases CO2 stored underground for millennia, burning biomethane releases CO2 that was recently absorbed from the atmosphere by organic matter. This supports the natural carbon cycle and enhances sustainability.

From waste to value

Our use of biomethane goes beyond a simple fuel switch. It has become a cornerstone of our circular economy strategy. Biomethane production captures methane from decomposing mainly manure, agricultural residues, food waste, and other organic materials, preventing greenhouse gas emissions while generating valuable renewable energy. This approach transforms waste streams into economic value while mitigating environmental impact.

Locally produced

We endorse the use of biomethane sourced from local and regional European producers, supporting European farmers. This approach minimises transportation emissions related to feedstock transportation, fosters resilient supply chains and strengthens local economies in the regions where we operate.

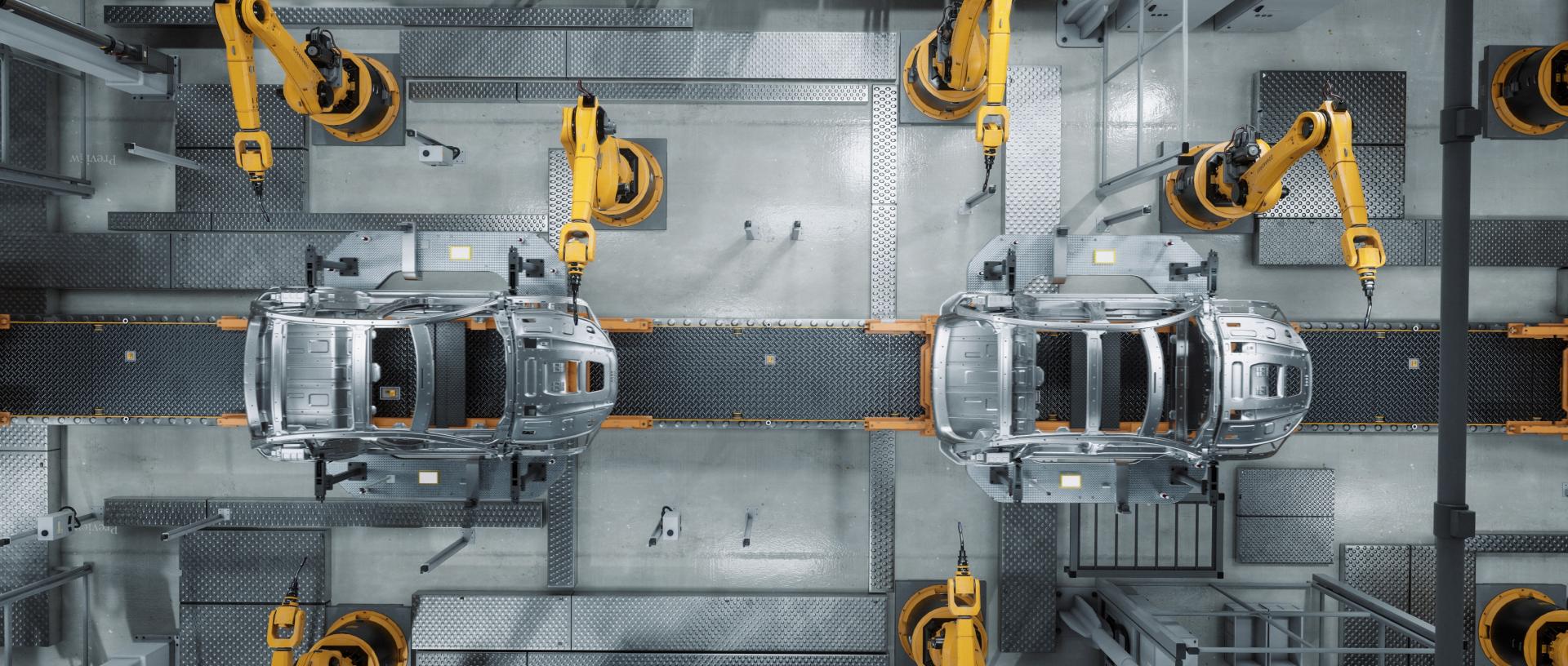

Making steel with biomethane

At Tata Steel Nederland, we have explored multiple pathways to replace natural gas with biomethane in various heating processes. In 2024, we achieved CO2 reductions through two key projects. In IJmuiden, we replaced natural gas with biomethane for heating processes, adding the CO2 savings to our carbon bank to help customers lower their carbon footprint through our Zeremis Carbon Lite solution. Additionally, our Steel Service Centres, MultiSteel and Feijen in Maastricht, achieved carbon neutrality for Scope 1 and 2 emissions by switching to biomethane.

We now foresee a substantial role for biomethane in both our current and future steelmaking processes. However, while biomethane is the most cost-effective sustainable alternative to natural gas, it remains significantly more expensive. As a result, scaling up its use depends heavily on support from Zeremis funding.

By applying our carbon reduction solution, Zeremis Carbon Lite, our customers reduce their Scope 3 emissions. At the same time, they contribute to the broader adoption of biomethane in steel production and other decarbonisation initiatives at Tata Steel Nederland.

Ultimately, biomethane is set to become one of the most relevant renewable gases, now and in the future. Its adoption enhances circularity and supports Tata Steel Nederland’s ambition to become a green, clean, and circular steel producer.

Independently assured

In Europe, biomethane must meet strict sustainability criteria under the EU Renewable Energy Directive (RED), including compliance with a list of approved sustainable feedstocks. Tata Steel Nederland exclusively sources biomethane certified by an EU-recognised voluntary or national certification scheme, ensuring compliance with RED requirements. For example, the EU-recognised ISCC EU scheme not only meets but exceeds RED criteria by incorporating additional ecological and social standards. At the same time, our carbon bank and Carbon Lite scheme, which facilitate transparent customer reporting, are independently assured by DNV (Det Norske Veritas).

Implement now through Carbon Lite

Given last year’s successful sourcing of the first sustainable volumes, we have paved the way for subsequent biomethane purchases, which now can be directly and easily implemented via our Carbon Lite scheme. We are exploring the purchase of larger volumes of biomethane to replace natural gas usage at various units across our sites in IJmuiden and at our downstream locations. Also in the long run, we aim to replace natural gas with biomethane at various points throughout our process. Looking ahead, our long-term goal is to integrate biomethane into various stages of our production process, further advancing our transition towards sustainable steelmaking.