Custom-made for batteries

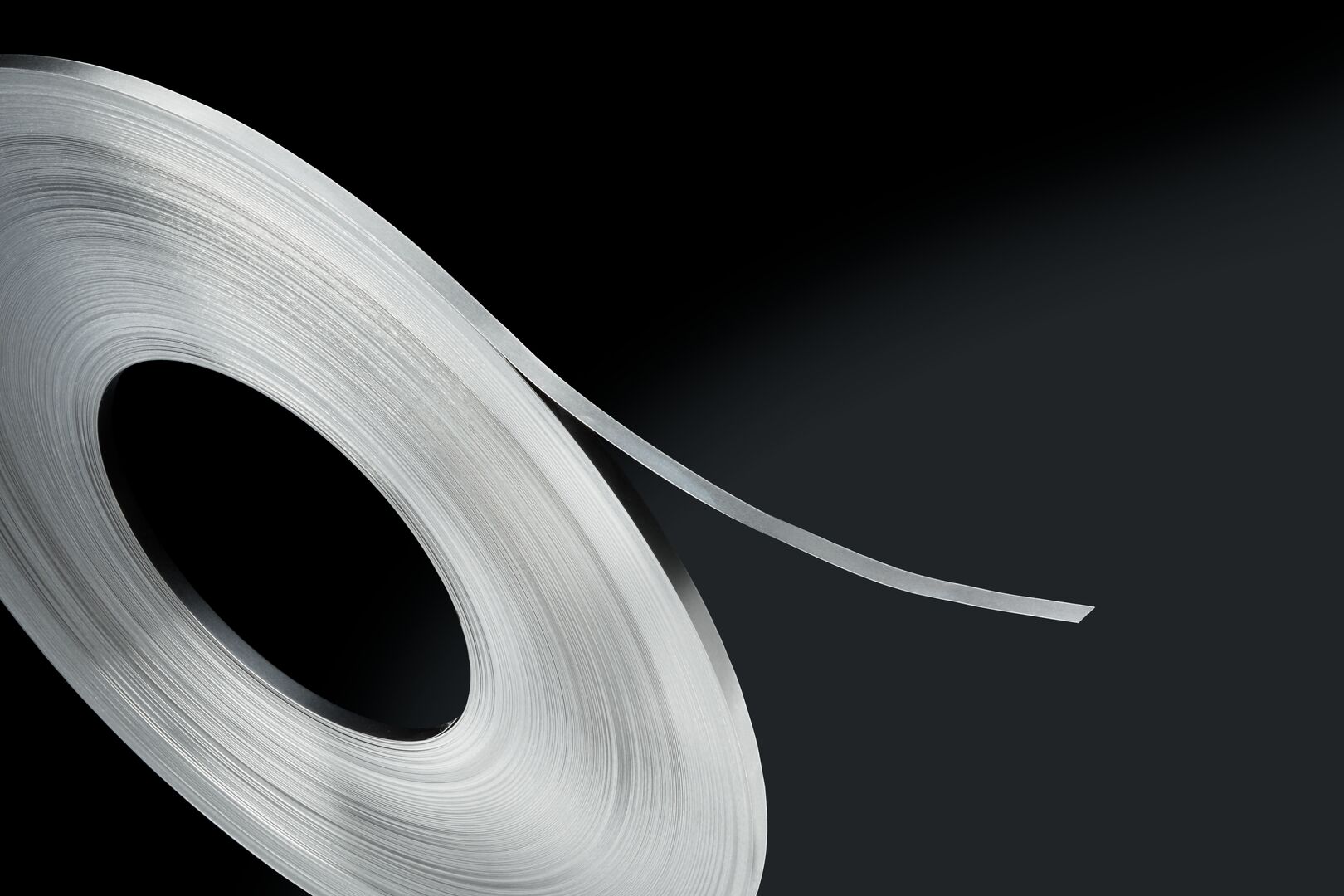

Tata Steel Plating is the world's leading supplier of materials for the production of battery cases. HILUMIN, the nickel-coated steel strip is specifically developed for battery applications. It is created by electroplating cold-rolled battery quality steel with nickel and diffusion annealing. HILUMIN offers low contact resistance and high corrosion resistance. It is used in alkaline battery cans (including AA, AAA, C, D and 9V) and all other battery types including rechargeable and ZincAir.

HILUMIN Cobalt has an additional thin Cobalt layer on top of the nickel coating for extended shelf life.

HILUMIN offers the coating and mechanical properties that you require for high speed can making and contribute to cell reliability so our customers can guarantee up to ten years of shelf life .

HILUMIN is produced from ultra-clean, specially-cast steel. Our proven and dedicated plating and heat treatment process ensures high corrosion resistance for long battery life. The consistent quality of HILUMIN also meets the demands of high volume, high speed battery component production. HILUMIN is custom-made for each application and is available for any battery type (alkaline, lithium, NiMH, NiCd and Li-Ion, Zn Air). It is also available as perforated steel strip. HILUMIN comes in a wide variety of finishes and offers:

-

outstanding formability (with excellent adhesion) for high-speed can-making and cell assembly

-

excellent corrosion resistance and low contact resistance

-

excellent deep drawing capability

-

consistent mechanical properties and tight tolerances

-

low earing characteristics

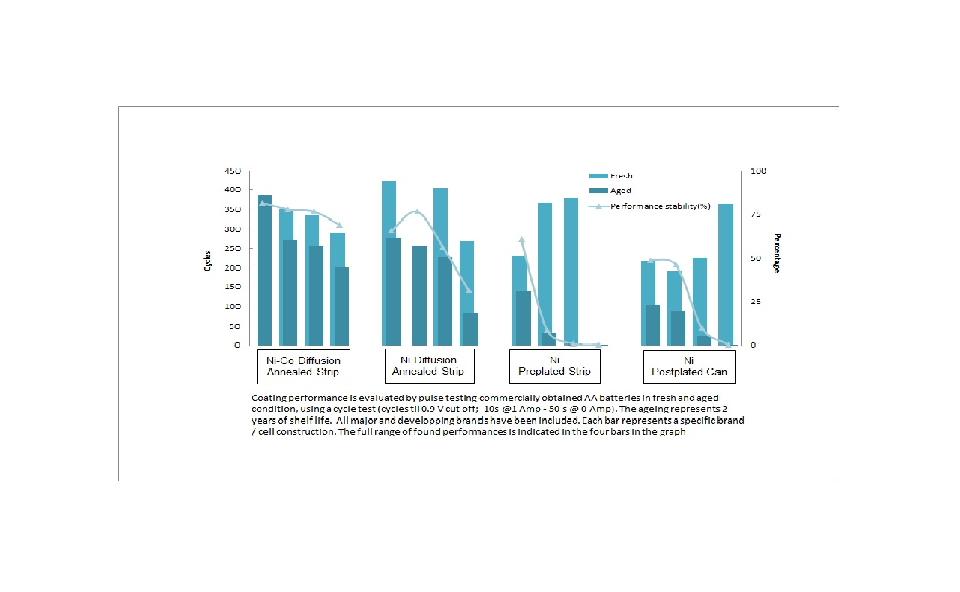

Extended shelf life

For an even more advanced coating performance, HILUMIN Cobalt offers additional cobalt plating as a top coating. This HILUMIN cobalt strip outperforms the traditional alkaline battery can - enhancing cell performance considerably after ageing. If you are concerned about edge corrosion, we can also provide our HILUMIN coating on top of stainless steel.

Main benefits of HILUMIN include:

-

end-products of consistent and reliable quality

-

opportunities to enhance end-product performance

-

trouble-free, repeatable processing

-

scope to optimise processes

-

minimised yield loss

Delivery conditions

|

Delivery condition |

Available temper |

Thickness range |

Nickel plating thickness |

Width range |

|||

|---|---|---|---|---|---|---|---|

|

|

|

mm |

inch |

μm |

µinch |

mm |

inch |

|

A, LC, C290, C340, C390 |

2T, 3T, 4T, 5T |

0.080 – 1.000 |

0.003 – 0.040 |

0.2 – 4.0 |

8 – 160 |

3 – 800 |

0.10 – 31.5 |

Surface appearance

|

Surface Finish |

Code |

Ra (µm) |

Description |

|---|---|---|---|

|

Bright finish (BF) |

KR 0.5 |

≤ 0.2 |

very smooth surface |

|

Fine stone finish |

KR 4 / #2 Finish |

0.15 - 0.45 |

smooth surface |

|

Matte finish |

KR 7 / #1 Finish |

0.6 - 1.8 |

matte surface |

|

Rough matte finish |

KR 8 / #1 Finish |

1.0 - 2.5 |

rough matte surface |

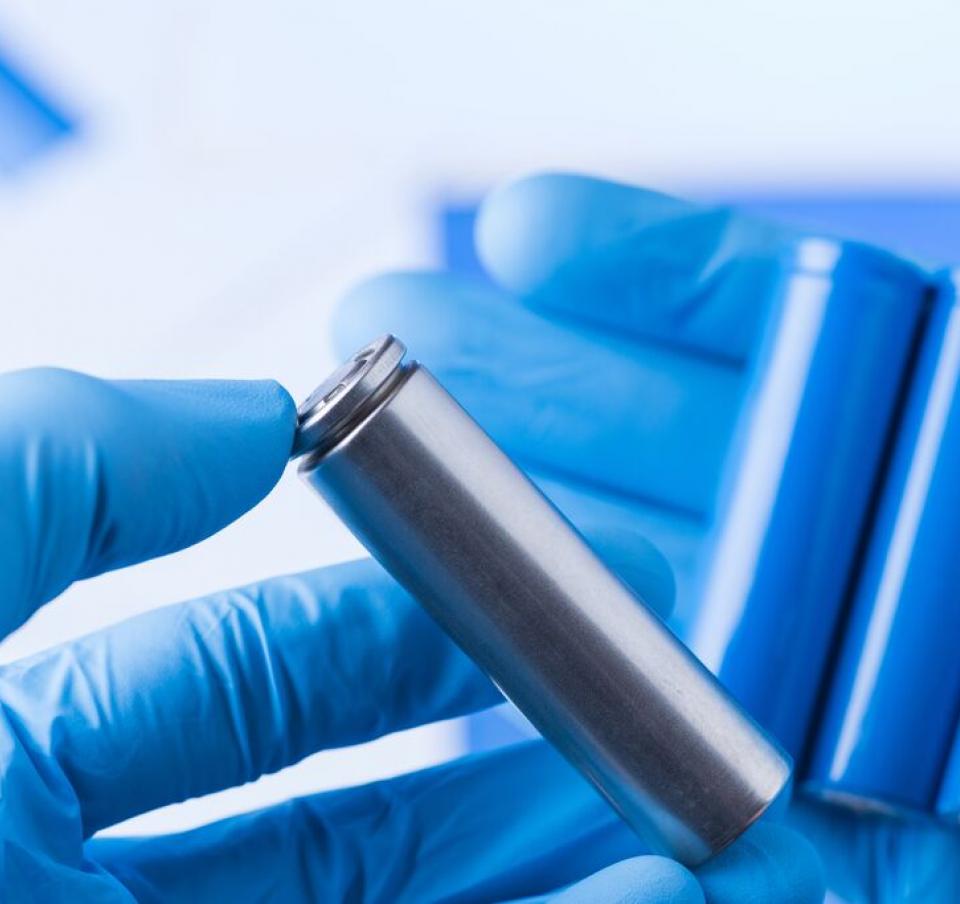

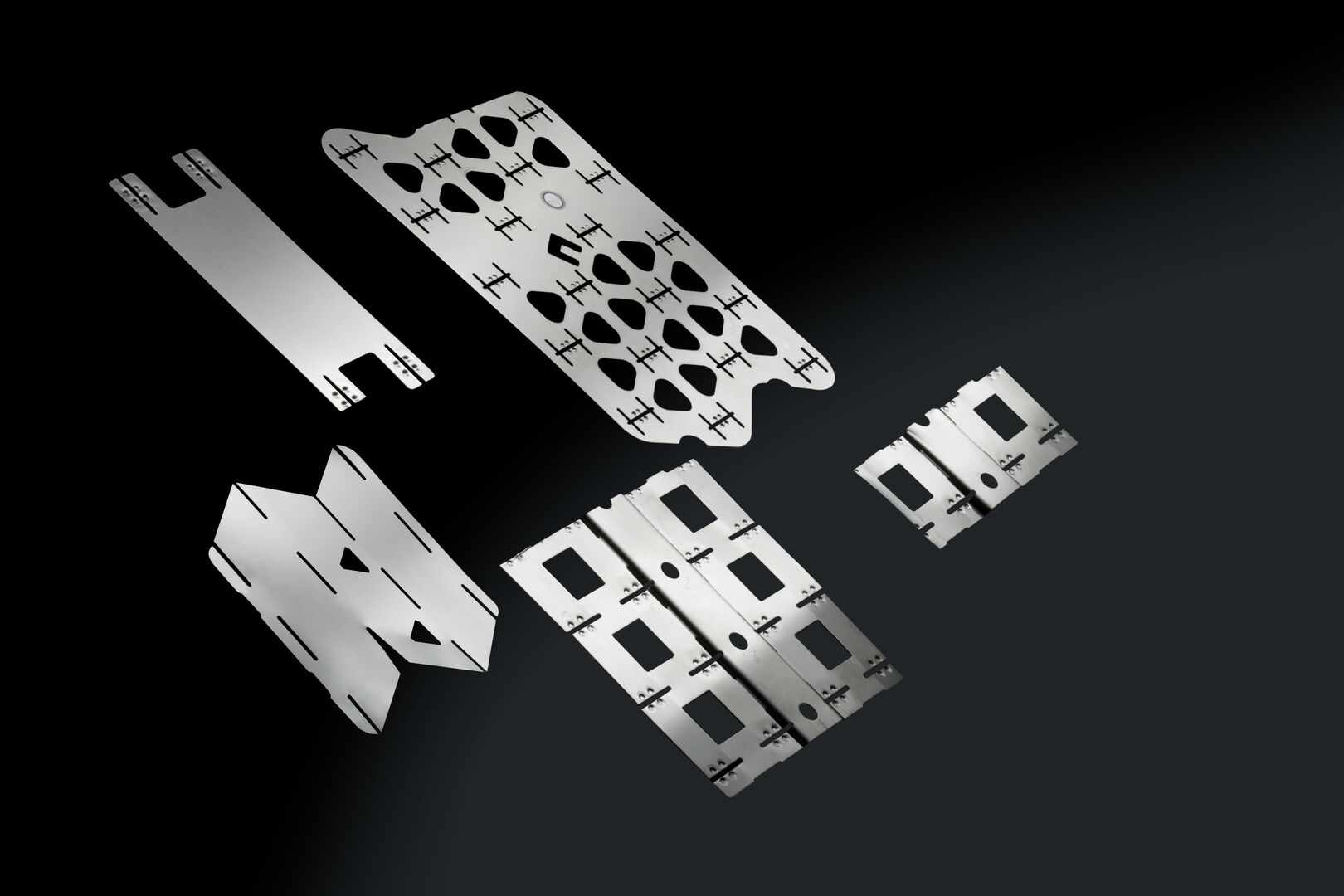

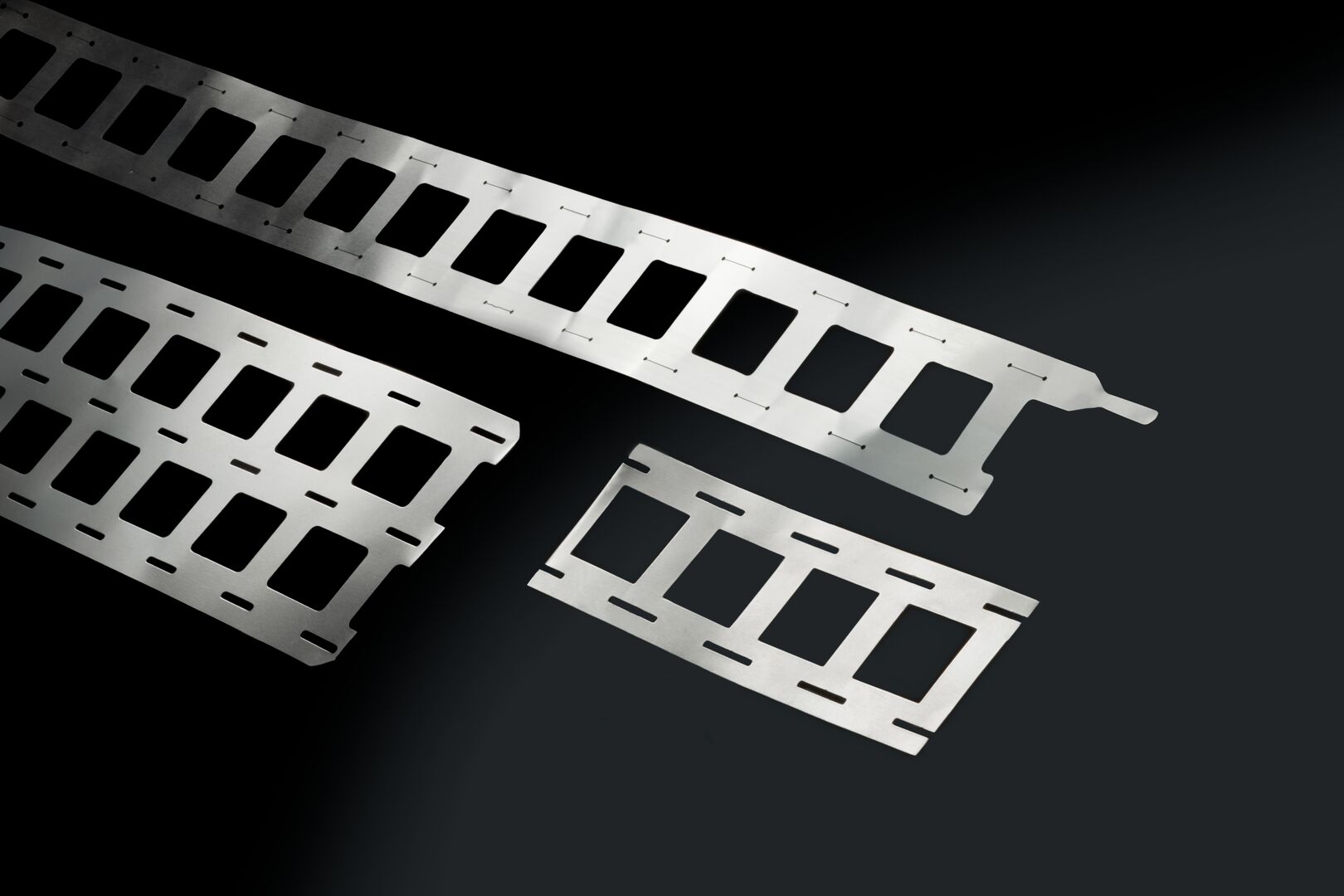

Applications

HILUMIN is used in a variety of battery related products. It low contact resistance does not only make it the material of choice for battery cases, but also for different types of battery cell connectors.

- Battery cell cases

- Alkaline

- Lithium ion

- Nickel Metal Hydride

- Zinc Air

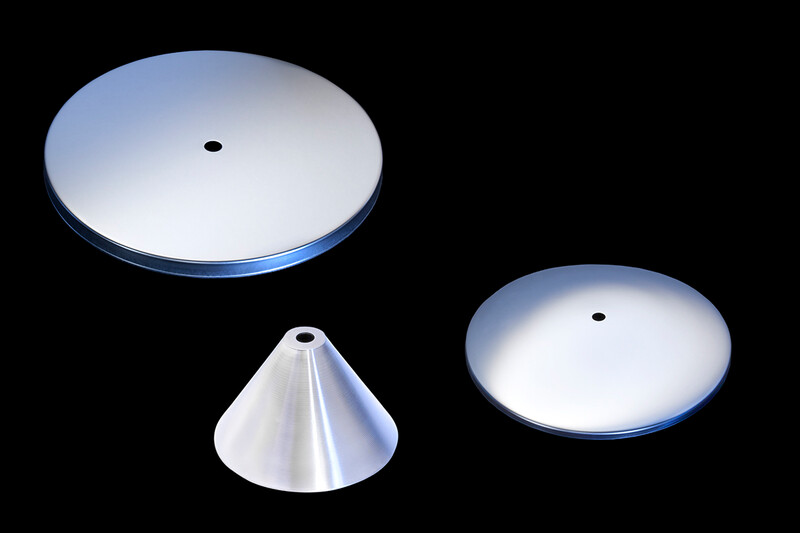

- Battery cell covers

- Battery cell connectors

- Battery system connectors

- Battery bi-polar plates

EN-Plating-Contact-Hille and Muller general

General enquiries

Tata Steel Plating

Head Office

c/o Hille & Müller GmbH

Am Trippelsberg 48

D-40589 Düsseldorf