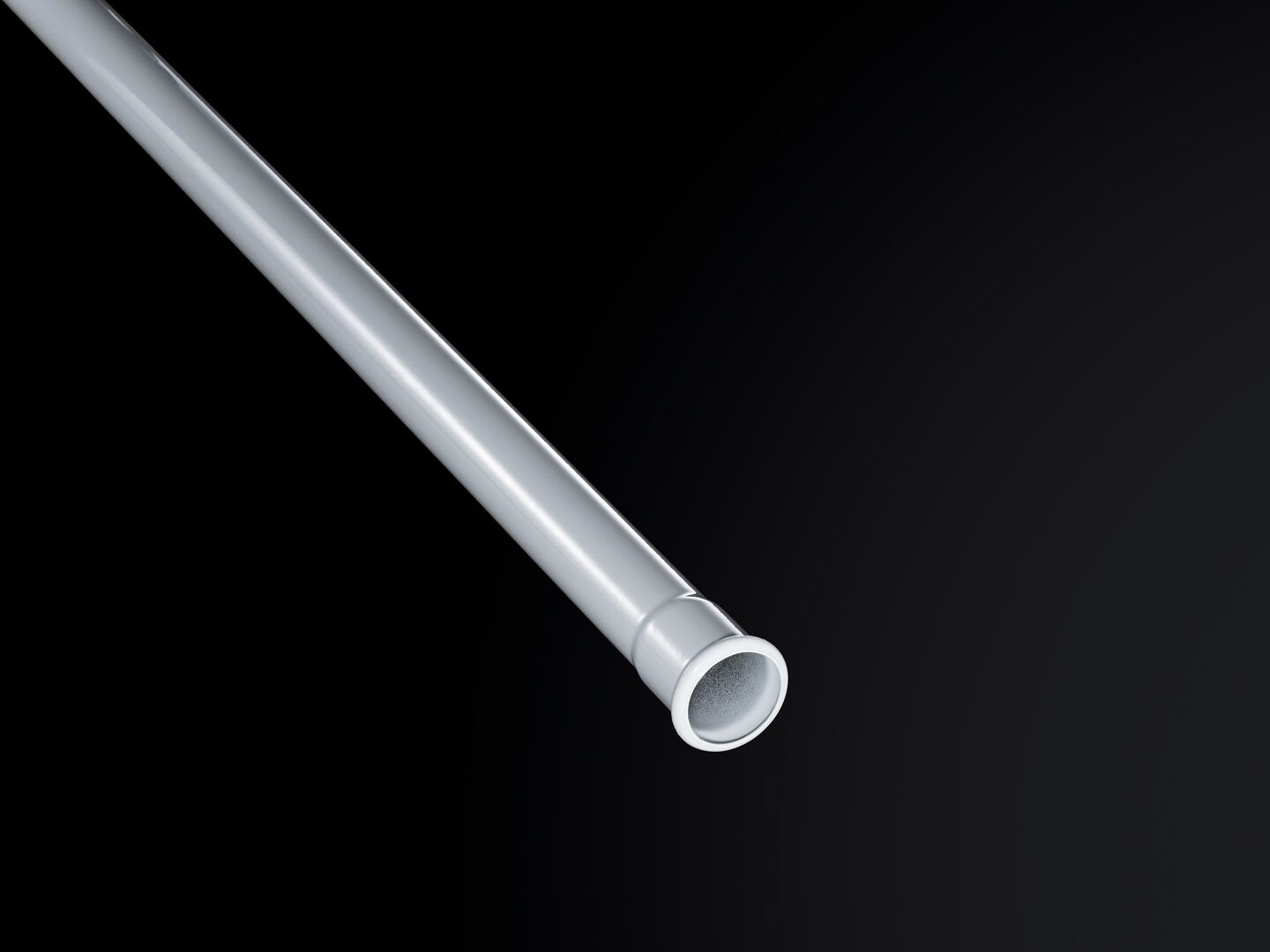

Contiflo®

Premium galvanised steel tubes for precision applications supplied to EN10305-3

Contiflo® is a steel precision tube, thermally zinc-coated in line. Manufactured in Oosterhout in the Netherlands, our range of Contiflo® pre-coated tubes offers superb corrosion resistance, great durability and excellent aesthetics.

Our special inline galvanising process ensures an exceptional robust and strong bond of the zinc layer and gives the tube a shiny finish. The tube is welded prior to the application of the coating; thus the weld area is as protected from corrosion as the rest of the tube body.

The galvanised surface of our tubes is passivated, offering further protection against the formation of unsightly white rust. This passivation process enhances the longevity and reliability of our tubes, making them an ideal choice for a wide range of applications, even in harsh environments.

EN-Tubes-Galvanised-Contiflo-Tubes

EN-Tubes-galvanised-Contiflo-Overview-TSN

Contiflo®

• Made with steel from a high quality production process

• Dimensional consistency and corner radius controlled 1.50-1.75x wall thickness

• High levels of bendability 2.0-2.5x external diameter

• Great surface quality

• Excellent corrosion resistance and great durability

• Available Extras: powder coating, cutting, marking, caps, customer-specific packaging etc.

Available Extras

- Fix lengths and lengths <4m

- Powder coating

- Marking

- Caps

- Customer specific packaging

- Digital solutions / EDI

- Zeremis® Carbon Lite: Our low carbon emission steel solution offering the potential for up to 90% reduction in CO2 intensity.

- Special Features for Specific Applications: We are happy to explore the capabilities to meet your specific requirements.

Dimensions

Lengths:

Standard from 4-10m

Optional fix lengths and lengths <4m

Size range:

Circular 10 – 76.10mm

Square 10x10 – 30x30mm

Rectangular 20x10 – 40x30mm

Other cross sections are also possible

EN-Tubes-Product-Galvanised-Tubes-applications

Contiflo®

- Central heating systems

- Industrial packaging

- Automotive parts

- Greenhouse construction

- Roof construction

- Recreational equipment

- Fencing

- Household appliances

Forcas®

- Greenhouse heating systems

EN-Tubes-Product-Galvanised-Properties

Contiflo®

Steel quality

Steel in accordance with EN10111 and EN10130

Zinc thickness:

7-12µm as standard

12-25µm semi heavy duty

>25µm heavy duty

External protection:

Durable protection of the zinc layer from white rust is provided by a passivating coating

Internal protection:

Dried synthetic emulsion treatment or an internal water based coating.

Finishing Options:

On request, powder coating, cutting, marking, caps etc.

Bendability:

2-2.5x external diameter

Customer specific packaging is possible

Forcas®

Steel quality

Steel in accordance with EN10111 and EN10130

The outside is in-line thermally galvanised (Contiflo®) and then coated with a white flexible powder coating

EN-Tubes-Product-Galvanised-Tolerances TSN

Contiflo®

Circular, square and rectangular precision tubes with tolerances according to EN10305-3

Corner radius of square and rectangular sections:

1.5-1.75 x wall thickness

Forcas®

Circular powder coated precision tubes with tolerances according to EN10305-3

EN-Tubes-Product-Galvanised-Supply conditions TSN

Certification

2.2 test report or, if specific inspection is agreed, an inspection certificate 3.1 in accordance with EN 10204

EN-Tubes-Contact-Contiflo-TSN

Tata Steel Nederland Tubes

Souvereinstraat 35

4903RH Oosterhout

Netherlands