Forcon®

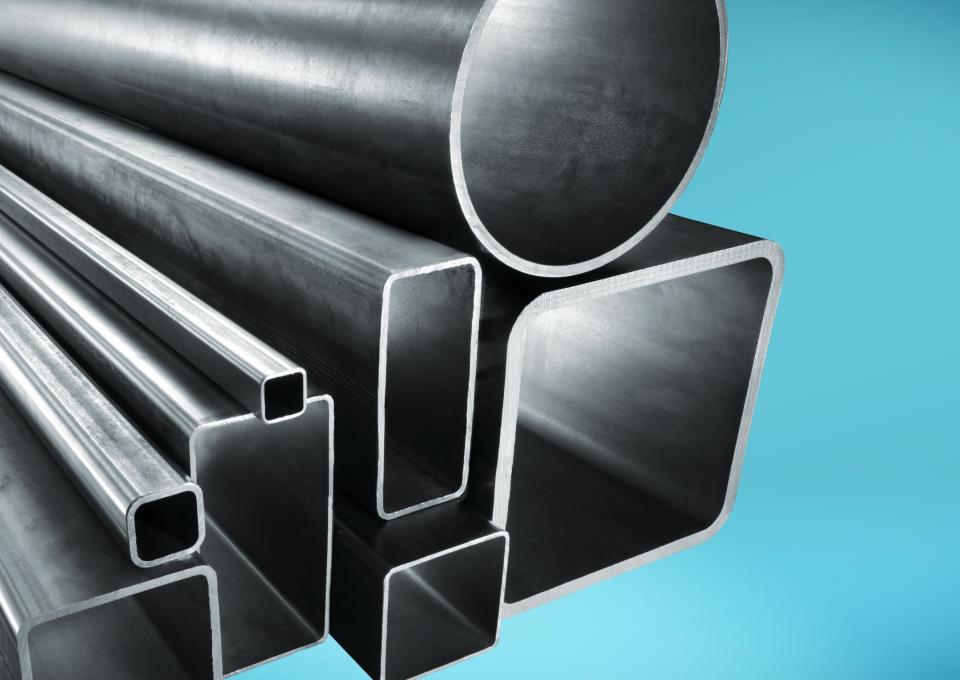

The consistent hollow section to EN10219 is available with minimum yield strengths ranging from 235 MPa to 700 MPa. Proven over many years in the field, this premium cold formed welded structural hollow section is perfect for a wide range of construction and engineering applications.

Forcon® TT

The tailored tube with additional features to Forcon®, customised to your requirements. You can choose from several premium options - for example tighter dimensional tolerances, a certain position of the weld seam or a scarfed internal weld bead, a superior surface finish or special bundling. This delivers multiple benefits for automated manufacturing processes.

EN-Construction-Product-Forcon-default

Forcon®

EN-Construction-Product-Forcon | Features and benefits

Reliable quality

Our Forcon® grades are manufactured to exacting standards, delivering consistent quality and precise dimensional tolerances for optimal results.

Efficient for processing, fabrication, assembly and end use

The optimum fit with advanced dimensional consistency and surface quality, excellent weldability and galvanisability, the variety of steel grades including high strength and the availability of long lengths.

Tailored to meet your needs

Whether it's future designs requiring low weight, high strength and automated processing or renovation projects with unique challenges - we have the solutions to meet your needs.

Knowledgeable experts who understand your business

With over a century of expertise in tube manufacturing and a deep commitment to customer collaboration and research, we support you every step of the way. Our commercial and technical service team is here to help and speaks numerous languages.

Made in the Netherlands

Forcon® is locally produced in our tube mills in Maastricht and Zwijndrecht. Our fully integrated steel works in IJmuiden ensures the quality and traceability of our products throughout the whole supply chain.

EN-Construction-Product-Forcon | Technical specifications

Forcon® fully complies with the European standard for cold formed welded structural hollow sections, EN 10219.

Backed by our extensive customer service and technical expertise, this product is ideal for a variety of structural and engineering applications, especially those requiring consistent and reliable performance.

Forcon® are manufactured to high quality standards and are made from fully killed steel.

They are easy to process, offering high levels of formability, excellent weldability and galvanisability.

Size range:

Circular 31.8 – 323.9mm

Square 25x25 – 250x250mm

Rectangular 30x20 – 300x200mm

Lengths:

Standard lengths are 6m, 12m or 15m, depending on the size and production mill.

Special mill lengths from 4.5m up to 20m can be arranged upon request.

There are several premium extras. For example tighter dimensional tolerances, different weld seam options, a superior surface finish, a bespoke chemical composition, extra testing or special packaging. These are available as Tailored Tubes Forcon® TT .

Our team is ready to assist you to customise Forcon® TT to your needs.

EN-Construction-Product-Forcon-downloads

Documents for Forcon®

Please get in touch if you would like to receive the Dutch, German or French version of these publications

EN-Tubes-Product-Structural-ForconTT-Datasheet-InternalScarfing-TSN

Datasheet Forcon®TT Internal Scarfing

EN-ConstructionEngineering-Download-EPD-Tata Steel Structural hollow sections

EPD Forcon structural hollow sections

EN-Construction-Product-Forcon-DoPs

DoPs for Forcon®

EN-Tubes-Product-Structural-Forcon-DoP-S235JRH-2.2cert-TSN

DoP - Declaration of Performance Forcon® 235

EN-Tubes-Product-Structural-Forcon-DoP-S275J0H-2.2cert-TSN

DoP - Declaration of Performance Forcon® 275J0H

EN-Tubes-Product-Structural-Forcon-DoP-S275J2H-3.1cert-TSN

DoP - Declaration of Performance Forcon® 275J2H

EN-Tubes-Product-Structural-Forcon-DoP-S355J2H-TSN

DoP - Declaration of Performance Forcon® 355

EN-Tubes-Product-Structural-Forcon-DoP-S420MH-TSN

DoP – Declaration of Performance Forcon® 420

EN-Tubes-Product-Structural-Forcon-DoP-S460MH-TSN

DoP – Declaration of Performance Forcon® 460

EN-Tubes-Product-Structural-ForconTT-DoP-S235JRH-2.2cert-TSN

DoP – Declaration of Performance Forcon®TT 235 with 2.2 certificate

EN-Tubes-Product-Structural-ForconTT-DoP-S235JRH-3.1cert-TSN

DoP – Declaration of Performance Forcon®TT 235 with 3.1 certificate

EN-Tubes-Product-Structural-ForconTT-DoP-S275J0H-2.2cert-TSN

DoP – Declaration of Performance Forcon®TT 275J0H with 2.2 certificate

EN-Tubes-Product-Structural-ForconTT-DoP-S275J0H-3.1cert-TSN

DoP – Declaration of Performance Forcon®TT 275J0H with 3.1 certificate

EN-Tubes-Product-Structural-ForconTT-DoP-S275J2H-TSN

DoP – Declaration of Performance Forcon®TT 275J2H

EN-Tubes-Product-Structural-ForconTT-DoP-S355J0H-TSN

DoP – Declaration of Performance Forcon®TT 355J0H

EN-Tubes-Product-Structural-ForconTT-DoP-S355J2H-TSN

DoP – Declaration of Performance Forcon®TT 355J2H

EN-Tubes-Product-Structural-ForconTT-DoP-S355K2H-TSN

DoP – Declaration of Performance Forcon®TT 355K2H

EN-Tubes-Product-Structural-ForconTT-DoP-S355MH-TSN

DoP – Declaration of Performance Forcon®TT 355MH

EN-Tubes-Product-Structural-ForconTT-DoP-S355MLH-TSN

DoP – Declaration of Performance Forcon®TT 355MLH

EN-Tubes-Product-Structural-ForconTT-DoP-S420MH-TSN

DoP – Declaration of Performance Forcon®TT 420MH

EN-Tubes-Product-Structural-ForconTT-DoP-S420MLH-TSN

DoP – Declaration of Performance Forcon®TT 420MLH

EN-Tubes-Product-Structural-ForconTT-DoP-S460MH-TSN

DoP – Declaration of Performance Forcon®TT 460MH

EN-Tubes-Product-Structural-ForconTT-DoP-S460MLH-TSN

DoP – Declaration of Performance Forcon®TT 460MLH

EN-Tubes-Contact-TSN

Tata Steel Nederland Tubes

Souvereinstraat 35

4903RH Oosterhout

Netherlands