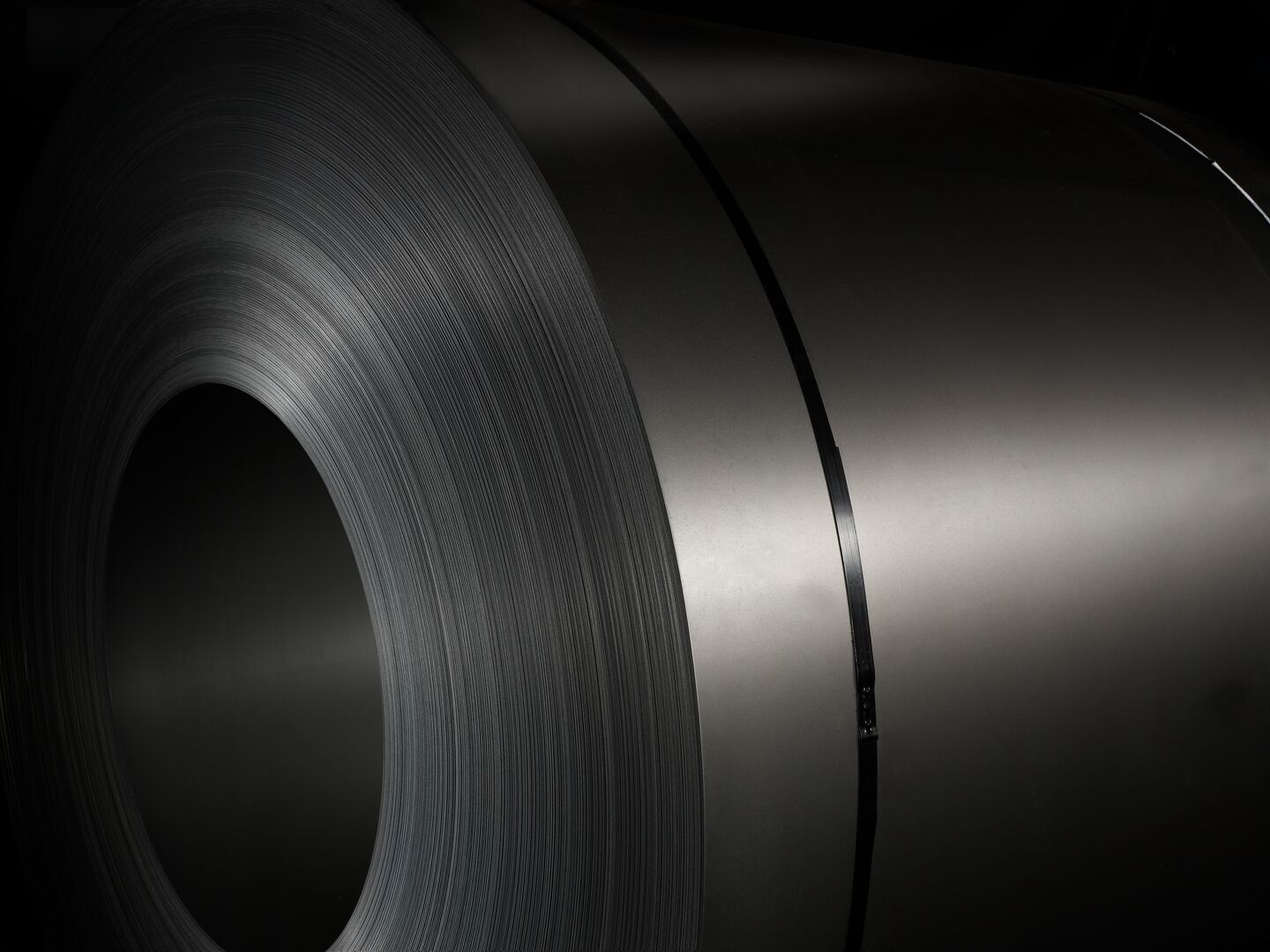

At Tata Steel Plating we have seven electro-plating lines on two continents producing copper, brass, nickel (cobalt) and nickel-zinc plated cold-rolled steel strip for demanding industries.

| Nickel (Cobalt) | Ni-Zn | Brass | Copper | |

|---|---|---|---|---|

| Gauge (mm) | 0.08 - 1.8 | 0.1 - 1.7 | 0.2 - 1.7 | 0.1 - 1.8 |

| Width (mm) | 3 - 800 | 3 - 724 | 3 - 724 | 3 – 830 |

| Plating (µm) | 0.2 - 6.0 | 0.5 - 5.0 | 1.5 - 5.0 | 1.0 - 6.0 |

| Locations | Hille & Müller | Thomas Steel | Apollo Metals | Apollo Metals |

| Thomas Steel | SC Wallau | SC Wallau | Hille & Müller | |

| SC Wallau | SC Wallau |

Note: not all width / gauge / plating combinations are available at all sites

EN-Plating-Brochure-Plating product range overview

Plating product range overview

Manufacturing Sites

Apollo Metals, Ltd., Bethlehem, Pennsylvania, USA

Apollo Metals has been electroplating continuous coil at its Bethlehem, Pennsylvania, facility for more than 80 years.

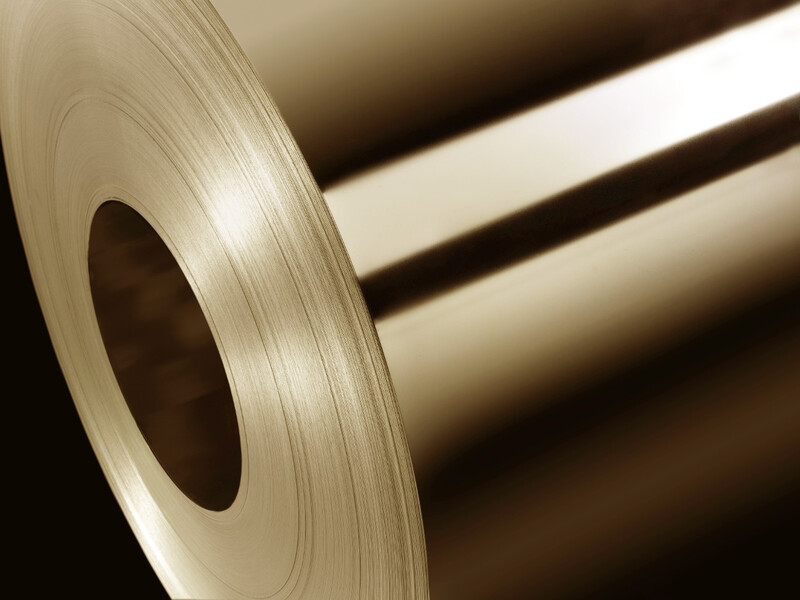

We produce copper and brass-plated cold rolled steel products in a diverse range of dimensions and surface finishes. Our products are used for:

- critical automotive and sporting ammunition applications

- a range of functional applications

- decorative product applications

Our electroplating process enables us to meet all customer expectations for product characteristics including:

- chemical properties

- corrosion resistance

- electrical conductivity

Apollo's state-of-the-art plating delivers optimised quality and overall product consistency. Our plating line configurations ensure extremely tight plating control.

We specialise in plating to exact tolerances - allowing our customers to produce at optimum efficiencies.

EN-Plating-Contact-Plating USA Apollo

Apollo Metals Ltd., USA

Apollo Metals Ltd.

1001 Fourteenth Avenue

Bethlehem, PA 18018

United States

Hille & Müller GmbH, Düsseldorf, Germany

Hille & Müller, Düsseldorf was founded in 1905 and is now the headquarters of Tata Steel Plating. It was the first company in the world to produce electroplated steel strip.

Over 115 years’ experience and a longstanding commitment to innovation have made Hille & Müller the world's leading expert in nickel-plated cold rolled strip. Excellent surface finish is a hallmark of our products. A wide choice of mirror finish and smooth, matte surfaces is available.

Our electroplating process enables us to meet all customer expectations for product characteristics including:

- chemical properties

- corrosion resistance

- electrical conductivity

Hille & Müller is renowned for consistently reliable manufacturing processes. These deliver customised products with exacting dimensional tolerances for diverse applications and requirements.

EN-Plating-Contact-Hille and Muller general

General enquiries

Tata Steel Plating

Head Office

c/o Hille & Müller GmbH

Am Trippelsberg 48

D-40589 Düsseldorf

Thomas Steel Strip Corp., Warren, Ohio, USA

With a history dating back to the early 1920s, Thomas Steel Strip is today recognised as a world-class industry leader in plating.

Whether your applications require cold-rolled or plated steel, you can be confident that Thomas Steel will provide products that meet the highest levels of dimensional and plating layer precision.

Our combination of equipment and capabilities ensures we can offer a flexible customer service. We can:

- meet customer needs for smaller volumes (much like a service centre)

- respond to customer production requirements for larger volumes

Our electroplating process enables us to meet all customer expectations for product characteristics including:

- chemical properties

- corrosion resistance

- electrical conductivity

As a pioneer of many new technologies, Thomas Steel Strip supplies a wide range of steel products. These are:

- cold rolled

- nickel-plated

- nickel-cobalt-plated

- nickel-zinc (NiZn)

EN-Plating-Contact-Plating USA Thomas Steel

Thomas Steel Strip Corp., USA

2518 West Market Street,

Warren, Ohio 44485

USA

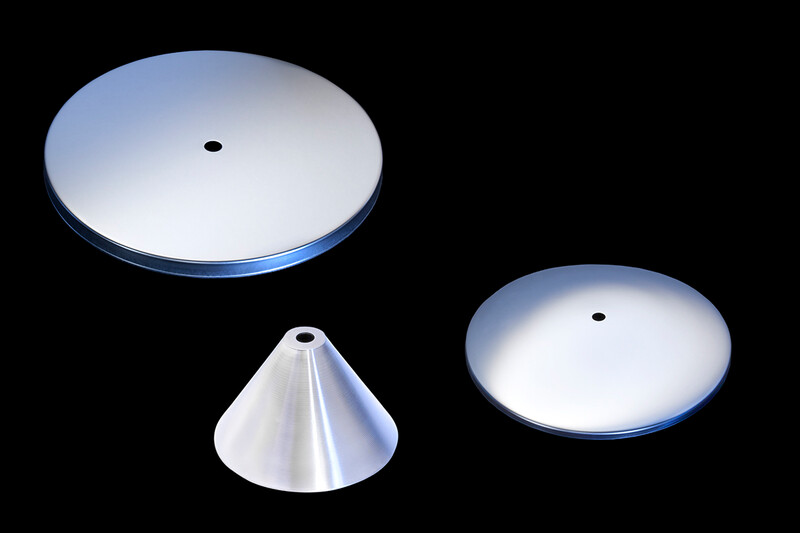

Plating's cold-rolled steel strip is used in a wide variety of end-user applications.

Our Hibrite® is a cold rolled steel with a brilliant surface appearance available in bright finish (BF) or mirror finish (MF) and enables our customers to eliminate additional processing steps such as grinding or polishing after grinding or forming.

EN-Plating-Contact-Hille and Muller general

General enquiries

Tata Steel Plating

Head Office

c/o Hille & Müller GmbH

Am Trippelsberg 48

D-40589 Düsseldorf