Tata Steel has developed boron manganese steel products for agricultural machinery with consumables and spare parts specialist FRANK Walz- und Schmiedetechnik GmbH. Manufacturing expertise and Tata Steel’s excellent quality and delivery performance have been pivotal in this partnership.

FRANK Walz- und Schmiedetechnik GmbH

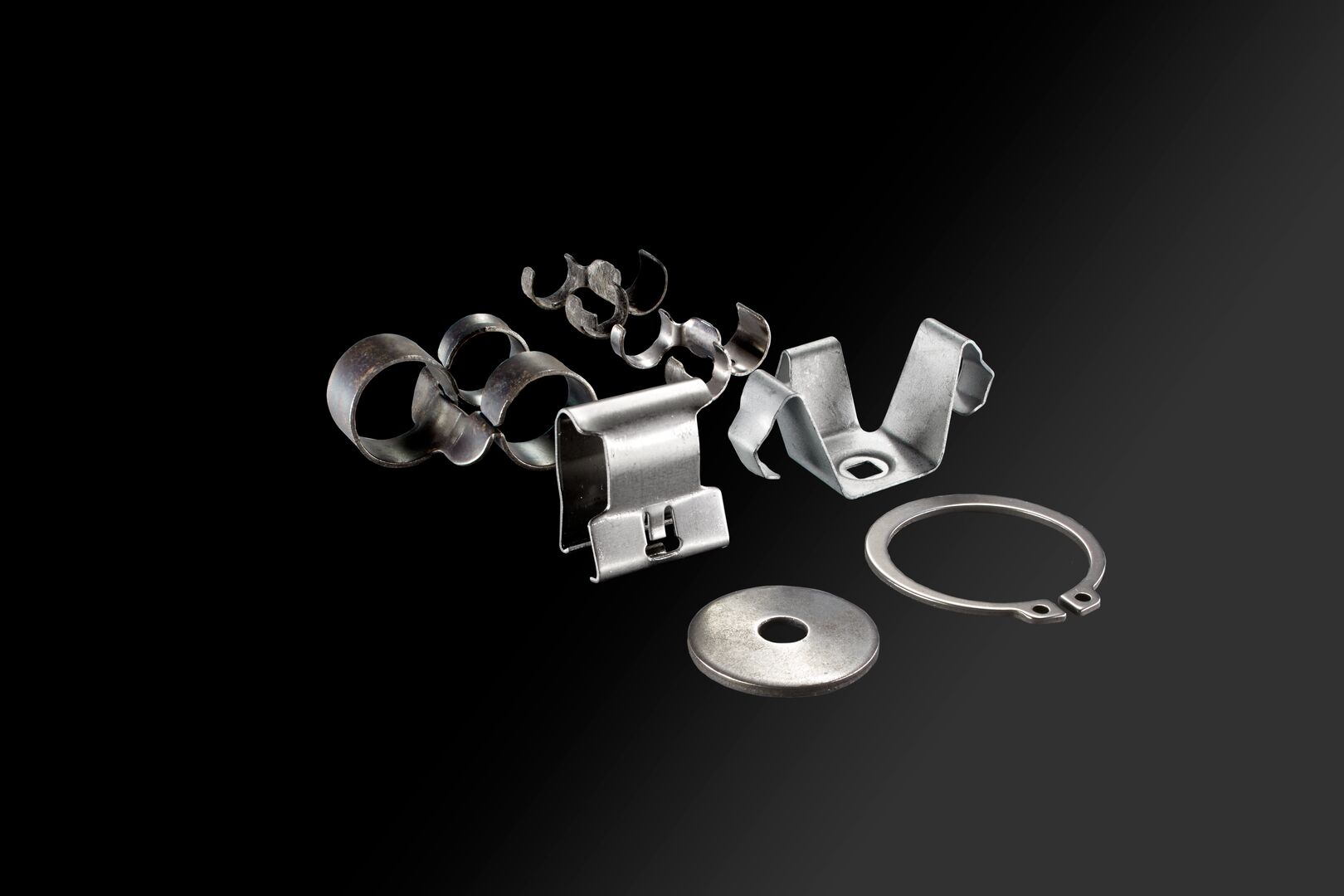

Agricultural equipment users expect their parts to be efficient, productive and robust. FRANK Walz- und Schmiedetechnik GmbH therefore uses boron manganese steel as one of its core materials when manufacturing its consumables and spare parts (e.g. 34MnB5). This traditional company from Hatzfeld (Eder) in Hessen, Germany, was looking for a reliable product development and production partner with excellent product and delivery quality in order to secure this strategically important supply chain in the longterm. It chose Tata Steel. The two companies joined forces to develop an individual boron manganese steel portfolio of flat steel products, tailored to end users’ requirements, which FRANK further processes on its own production sites.

EN-Engineering-Casestudy-MnB Frank Original

Boron manganese steel: Frank Original - Case study

DE-Engineering-Casestudy-MnB Frank Original

Bor-Mangan-Stähle: Frank Original - Fallstudie

The FRANK name has been synonymous with high-quality consumables and structural components for agricultural engineering and a wide range of industrial applications since 1836. The group currently employs around 500 people across six sites in Germany, Hungary, Ukraine and Russia. The product range consists of over 12,000 items, which are distributed to equipment manufacturers all over the world and to the aftermarket under the FRANK Original brand name. In order to maintain its leading position in terms of quality, the company focuses on making improvements throughout the entire value chain. Close, trusting cooperation with its suppliers is therefore an important part of FRANK’s quality assurance process.

Boron manganese steel increasingly used in agriculture

Agricultural equipment can be used day and night under varying conditions, whether that’s ploughing stony ground, mechanically weeding between delicate young plants or harvesting a potato crop. Boron manganese steel is increasingly used in agriculture to overcome these challenges and to prevent parts from becoming broken or worn too quickly. Boron manganese steel is a type of boron-alloyed tempered steel. These types of steel are characterised by their good formability at processing and solidity following heat treatment. The strength properties are provided by carbon and manganese additions with small quantities of boron amounting to a few thousandths of a percent.

Tata Steel as development and production partner

Boron manganese steel is critical for optimising complex structures of consumables and spare parts of ploughs, harrows and similar soil cultivation tools to ensure high-performance in agricultural engineering. This steel is therefore one of the core materials used by FRANK and for this reason is of strategic importance. This traditional company selected Tata Steel as its development and production partner to ensure long term, reliable supply of high-quality boron manganese steel.

True to its “Together we make the difference” strapline, Tata Steel added two new boron manganese steel products to its tempered steel portfolio in close cooperation with FRANK. Tata Steel currently offers hot-rolled dry boron manganese steel in 22MnB5, 26MnB5, 27MnB5, 27MnCrB5-2, 30MnB5, 34MnB5 and 38MnB5 grades. The steel is manufactured with a nominal thickness of 2.5 to 20.0 mm and in widths of 1000 to 2070 mm. The boron manganese steel produced by Tata Steel can be used in many different components for which FRANK needs flat steel, including plough shares, mouldboards, disc harrows or entire plough bodies. The steel is supplied by Tata Steel in Maastricht as hot-rolled dry cut-to-length sheets with a width of 1500 mm in several thicknesses and lengths. FRANK ensures that the hardness of the end product is achieved by the heat treatment carried out in its own factories.

34MnB5

One of the boron steel grades that is increasingly used by FRANK is 34MnB5. This kind of steel, which is not yet common in the agricultural equipment market, can be processed to create relatively complex shapes. Hardness values of 52 to 54 HRC (Rockwell hardness test) can be achieved after quenching and tempering. These values guarantee the hardness and high abrasion resistance of the end product, which are essential in challenging areas of application with high levels of component stress. The life expectancy of the end product will also have a positive effect on the sustainability values of customers as well as Tata Steel.

As a specialist, FRANK Walz- und Schmiedetechnik GmbH expects demand for boron manganese steel with varying degrees of hardness (not solely the workhorse 30MnB5) to increase further in future. For example, 26MnB5 or 34MnB5 flat steel is already used in precision tubes in the automotive industry, where hardness combined with lightweight properties are required. On the other hand, 38MnB5 or higher flat steel is currently used – because of its good formability and temperability – for mowing or chopping blades in agriculture, for example.

For further information and to discuss how boron manganese steel can help to improve your manufacturing efficiency and your end products, please contact us at: E:connect.engineering@tatasteeleurope.com.