MagiZinc® is an innovative replacement for conventional galvanised steels. It provides superior corrosion protection even in harsh environments

Its unique formulation means that MagiZinc outperforms the protection of conventional galvanised steel.

Suitable for a wide range of indoor and outdoor applications, it can be used to reduce coating weight or extend product life. This means less use of valuable resources and reduced environmental impact.

Get in touch with us to discuss how MagiZinc can support your needs.

MagiZinc delivers significant benefits for both end-product performance and material processing

Its superior corrosion protection – even at cut edges - will extend product life and it offers excellent formability and weldability for efficient processing.

MagiZinc benefits include:

- Extended end-product life – delivering reduced maintenance and / or replacement costs

- Reduced production time and cost – through elimination of external batch galvanizing

- Ability to produce complex-shaped components with ease – saving assembly time and providing the opportunity to down-gauge

- Reduced environmental impact – through extended product life and reduced raw material consumption

Talk to our team about how MagiZinc can support your needs.

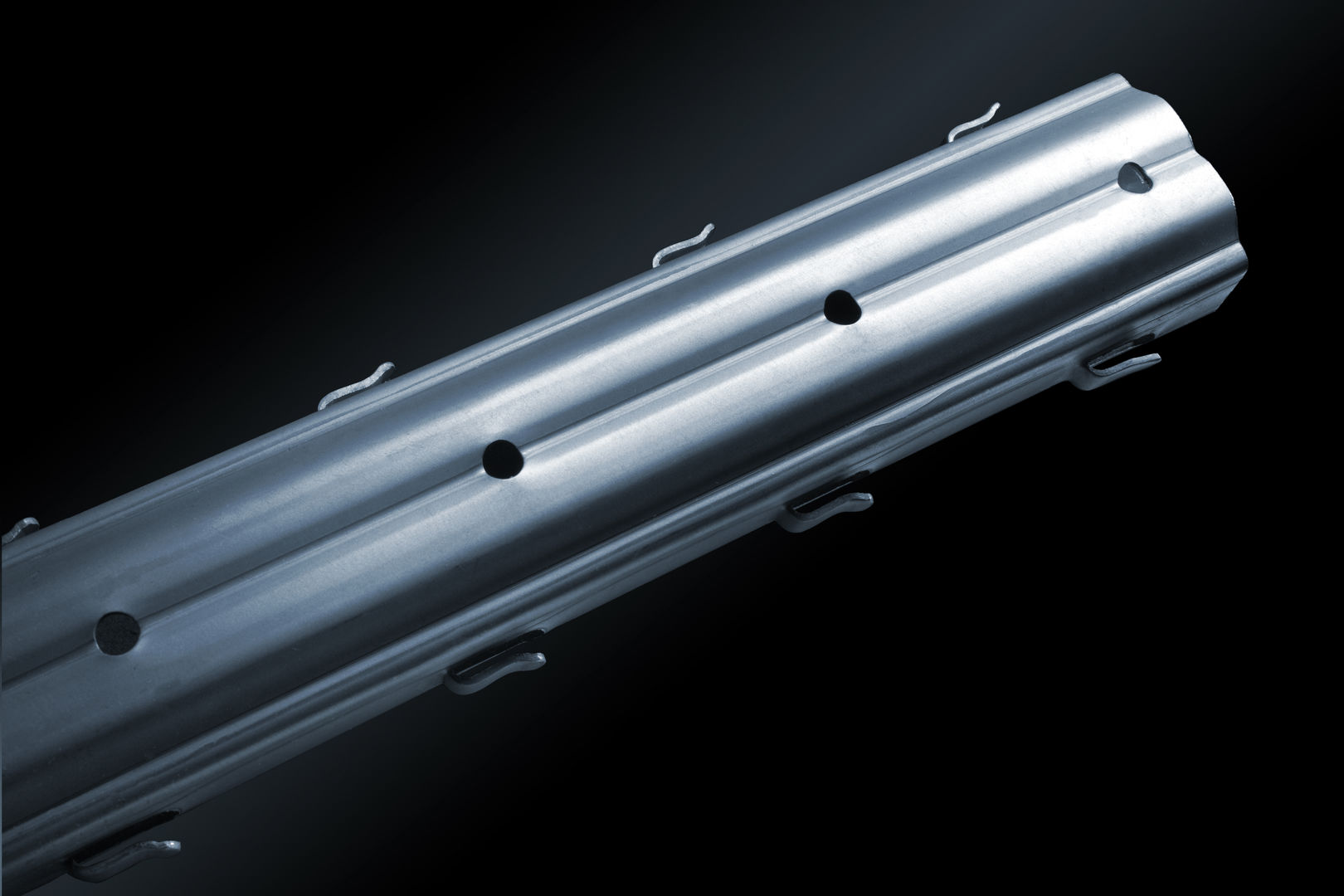

MagiZinc is a popular choice for the production of cold-formed steel profiles for solar panel supports

These structures are constantly exposed to the elements and are expected to perform for at least 25 years. The long-lasting corrosion protection provided by MagiZinc, combined with excellent formability, reduces component costs.

During its development, MagiZinc was subjected to extensive material application trials – including welding, roll forming and deep drawing - to ensure that it can be processed with ease. The surface hardness contributes to low tool pollution and low friction during deep drawing and roll forming – offering outstanding formability. The reduced coating thickness allows for a smooth welding process. A chromium-free passivating agent means MagiZinc is compatible with common paint systems.

During its development, MagiZinc was subjected to extensive material application trials – including welding, roll forming and deep drawing - to ensure that it can be processed with ease

The surface hardness contributes to low tool pollution and low friction during deep drawing and roll forming – offering outstanding formability. The reduced coating thickness allows for a smooth welding process. A chromium-free passivating agent means MagiZinc is compatible with common paint systems.

The superior protection levels delivered by MagiZinc mean increased product life expectancy. It offers an attractive alternative for outdoor applications where batch galvanised components are currently used or where components are produced from galvanised sheet with a thick zinc layer. MagiZinc delivers extended product life compared with conventional galvanised steel, even in demanding environments. For example, the unique barrier properties mean it offers long-lasting performance in ammonia-rich agricultural settings.

For engineering downloads such as brochures, case studies and data sheets, please click below: