Our well-proven packaging steel products include tinplate for drawn and wall ironed (DWI) cans and flow-brightened material for 3-piece cans. Our extra-wide tinplate (up to 1200mm) allows you to boost production output.

Short Lead times - Flexible, multi-site operations and a robust supply chain infrastructure mean we offer a responsive service. We can supply tinplate to match your production demands – in as little as two weeks.

Reliable performance - Our proven tinplate packaging steel offers reliable quality including homogeneous coating and consistently good shape – helping to ensure efficient processing and end-product performance.

We offer an extensive range of foodsafe tinplate to suit your packaging applications and processes. Our well-proven packaging steel products include tinplate for drawn and wall ironed (DWI) cans and flow-brightened material for 3-piece cans. Our extra-wide tinplate (up to 1200mm) allows you to boost production output.

Applications:

• DWI food and beverage

• 2-piece DRD, 3-piece bodies (including shaped bodies)

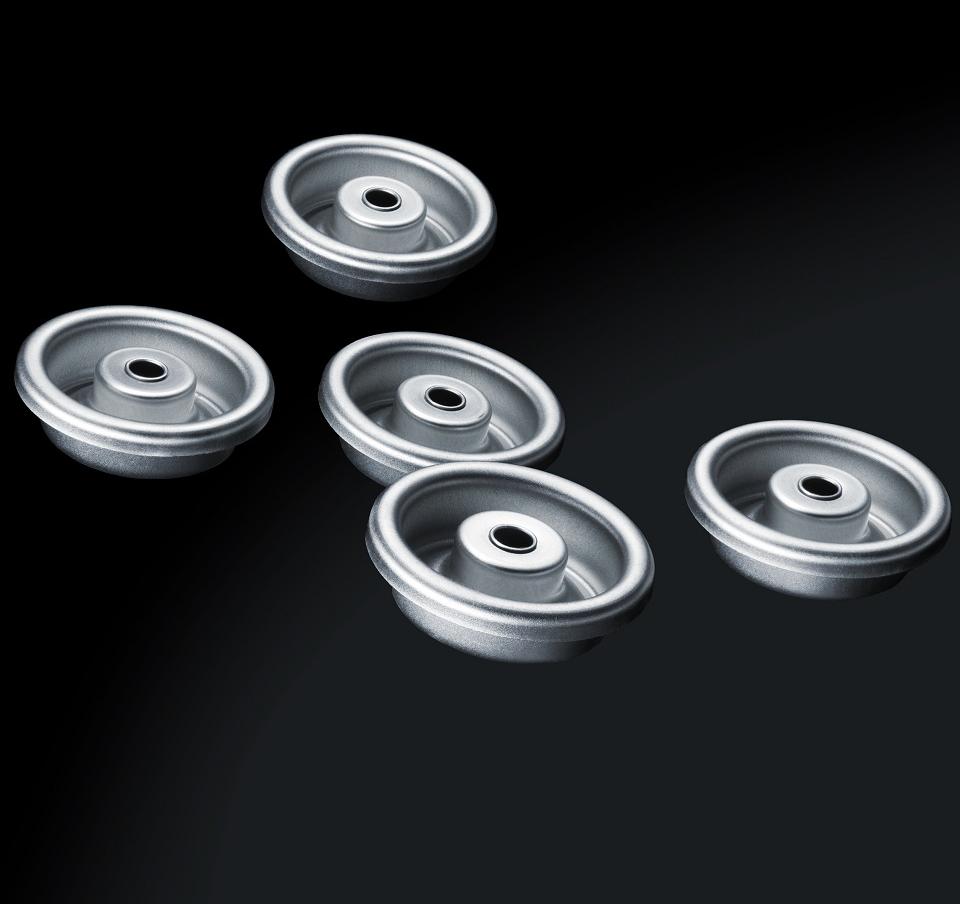

• aerosols

• easy-open ends, classic (standard) ends

• twist-off caps, • crown corks

• speciality packaging

Wide choice to meet your needs

We offer a wide choice of tinplate – tailoring our products to meet your required strength, surface finish and forming requirements. Our tinplate is produced using Tata Steel’s blackplate.

Bespoke tempering and investment in both batch and continuous annealing mean we can match requirements for a variety of tinplate applications.

We supply tinplate in a choice of:

- single reduced and double reduced steel grades – with material tempered to match your strength and ductility requirements

- thickness (gauge) – with scope for downgauging thanks to our direct rolling operations which produce thin-gauge material with increased strength

- coating weight – matching your corrosion-resistance requirements, with differential coatings clearly identified

- surface finish – to meet your processing needs and product performance requirements

- width - up to 1200mm for optimised operational flexibility and output

- oils – for protection in transit

Specialist operations at our rolling mills provide added choice and meet demands for:

- longer shelf life – through our optional passivation process which stabilises the tinplate surface and impedes growth of ‘yellowing’ tin oxide

- flow-brightened tinplate – produced through our flow-melting process which achieves the shiny, lustrous appearance and improved corrosion performance for welded 3-piece cans

Reliable quality for efficient canmaking and product performance

We have decades of experience in the manufacture of packaging steels. Our fully-traceable tinplate products benefit from the dependable quality of our blackplate feedstock and ongoing investment at our dedicated mills.

All of our processes – from initial pickling, through rolling, annealing, tempering and electrolytic tinning – are carefully controlled and monitored. Combined with rigorous inspection, including coating line auto-inspection equipment developed by Parsytec, this delivers tinplate with:

- reliable mechanical properties – including formability for DWI cans and earing properties for 2-piece drawn can production

- consistently good shape and dimensional tolerances – for efficient processing

- homogeneous tin coating – for reliable corrosion resistance, surface lacquering or printing

- excellent surface finish – at a roughness to match your requirement and achieved through careful control of both direct and temper mill rolling

New tinplate developments to serve you better

We continue to invest in our tinplate products and processes. This ensures ongoing product improvement – helping you to meet new challenges. In a world of tightening legislation for packaging material, it also means you can rest assured that our products will always be compliant.

Recent and current tinplate developments at Tata Steel include:

- development and implementation of a chromium-free passivation alternative to meet the European REACH regulation for chemicals

- ongoing low-weight coating optimisation – for cost-effective corrosion protection

- induction flow-brightening – delivering improved surface quality and enabling lower coating weights

Responsive service to suit your production demands

Our flexible, multi-site operations and robust supply chain infrastructure mean we can offer short lead times (as little as two weeks) to suit your production demands.

Tata Steel tinplate can be supplied in:

- coil or sheets

- DOS or ATBC oil

Our approachable tinplate experts are happy to advise you on the best products to meet your needs. Please contact us to discuss your requirements.

Our steel is supplied in accordance with the following standards:

| Tinplate and ECCS (TFS) | Blackplate |

|---|---|

| Euronorm 10202 | Euronorm 10205 |

| ASTM 623 (on request) | - |

Our operations are ISO 9001 certified.

Mechanical properties

| Yield / Proof | Tensile | Range | |||||

|---|---|---|---|---|---|---|---|

| Special | AISI / ASTM | BA / CA | SR / DR | strength (MPa) | strength (MPa) | (MPa) | |

| TS200 | Bake ware and extreme deformations | BA | SR | 200 | 320 | +/- 50 | |

| TS230* | T1 | BA | SR | 230 | 325 | +/- 50 | |

| TS245* | T2 | BA | SR | 245 | 340 | +/- 50 | |

| TS260* | BA | SR | 260 | 360 | +/- 50 | ||

| TS275* | T3 | BA | SR | 275 | 375 | +/- 50 | |

| TS290* | BA | SR | 290 | 390 | +/- 50 | ||

| TS345 | Aerosol components | BA | DR | 345 | 400 | +/- 50 | |

| TS480 | More formable DR grade | BA | DR | 480 | 505 | +/- 50 | |

| TS520 | Formable DR Grade | DR 7.5 | BA | DR | 520 | 545 | +/- 50 |

| TS550* | DR 8 | BA | DR | 550 | 575 | +/- 50 | |

| TH415* | T4 | CA | SR | 415 | 435 | +/- 50 | |

| TH435* | T5 | CA | SR | 435 | 460 | +/- 50 | |

| TH465N | Easy open ends | T5 | CA | SR | 465 | 495 | +/- 50 |

| TH465 | Sanitary ends | CA | DR | 465 | 480 | +/- 50 | |

| TH480 | Easy open and sanitary ends | CA | DR | 480 | 500 | +/- 50 | |

| TH520* | DR 7.5 | CA | DR | 520 | 540 | +/- 50 | |

| TH550* | DR 8 | CA | DR | 550 | 570 | +/- 50 | |

| TH550N* | Easy open ends | DR 8 | CA | DR | 550 | 560 | +/- 50 |

| TH580* | CA | DR | 580 | 590 | +/- 50 | ||

| TH620* | DR 9 | CA | DR | 620 | 625 | +/- 50 |

*Euronorm designation

Mechanical properties - D&I grades

Our tinplate for drawn and wall ironed (D&I) applications includes boron alloyed extra low carbon, continuously-annealed products to ensure excellent formability and highly efficient processing.

| D&I grades | Yield / Proof | Tensile | Range | ||

|---|---|---|---|---|---|

| (B&B and food) | BA / CA | SR / DR | strength (MPa) | strength (MPa) | (MPa) |

| TH340 | CA | SR | 340 | 360 | +/- 40 |

| TH360 | CA | DR | 360 | 380 | +/- 40 |

| TH380 | CA | DR | 380 | 400 | +/- 40 |

| TH415 | CA | SR | 415 | 435 | +/- 40 |

We can supply other packaging steels with special properties such as minimum earing and deep drawing properties – please contact us.

| Product | Coils/sheets1 | Sheets | |

|---|---|---|---|

| Thickness | Width | Cut length | |

| Single reduced (SR) | 0.17 - 0.49 mm | 700 - 1200 mm | 457 - 1137 mm (width max. 1018 mm) |

| Double reduced (DR) | 0.13 - 0.26 mm | 700 - 1200 mm | 457 - 1137 mm (width max. 1018 mm) |

| Wide DWI | - | Up to 1219 mm | - |

| Width tolerance | Standard trim | (- 0.00, + 3.00 mm) | |

| Special trim | (- 0.00, + 1.00 mm) | ||

| Super trim | (- 0.25, + 0.00 mm) | ||

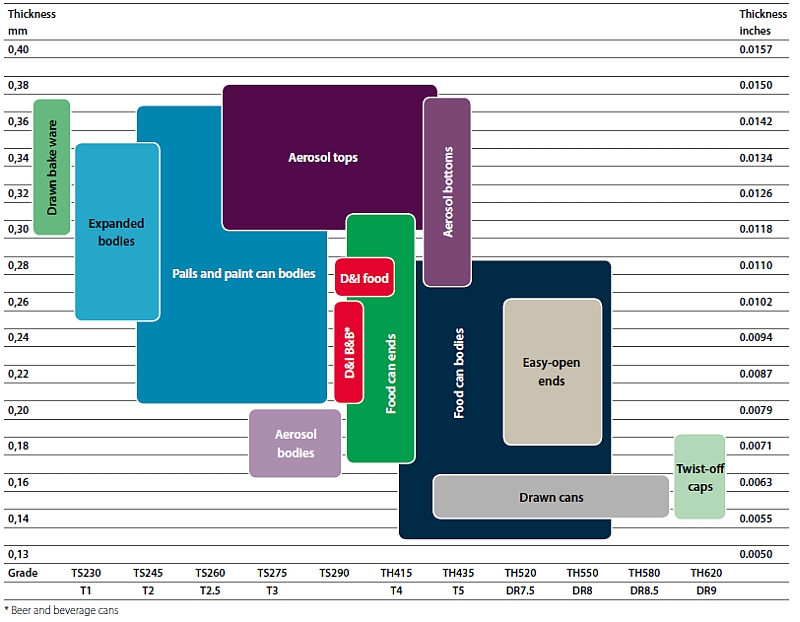

General specification window for packaging applications

Customer Technical Support

Our Customer Technical Support team supports you to get the most out of our packaging steels. Knowledgeable, approachable engineers provide practical advice to ensure the best product match for your application. We can work with you to optimize your processing efficiency and help improve your product’s performance. Supported by world-class research facilities at our Centre for Packaging Technology, we offer:

- material recommendations for smooth can-making processes

- process technology assessment to realize can-making line efficiencies

- can design reviews to improve can performance.

- logistics assessment to improve supply chain performance

- sustainability assessment to optimize today's can-making operations

Supply Chain Support

The day-to-day dynamics of the packaging supply chain demand a flexible supplier who can quickly anticipate changes in demand and specifications. We understand this – and that’s why you can count on us to meet deadlines. We have also developed innovative tools to simplify and shorten order lead times and improve information flow.

Our Supply Chain Support teams work with customers to:

- improve existing processes

- implement new supply chain processes for optimized efficiency, flexibility and performance

- reduce costs

The following downloads are available:

EN-Packaging-Brochure-Product range overview

Packaging steel - Product range overview

EN-Packaging-Datasheet - CFPA

CFPA tinplate for packaging datasheet

EN-Packaging-Brochure-APEAL - Chrome free passivation alternative

APEAL - Chrome free passivation alternative

Applications

EN-Packaging-Contact TSE

Contact our sales department

Packaging

PO Box 10000

1970 CA IJmuiden

The Netherlands