The XPF steel family is a major breakthrough in automotive structural material technology, suitable for chassis, body-in-white and seating applications

XPF's superior and robust product characteristics expand the potential to downgauge whilst improving product performance and productivity.

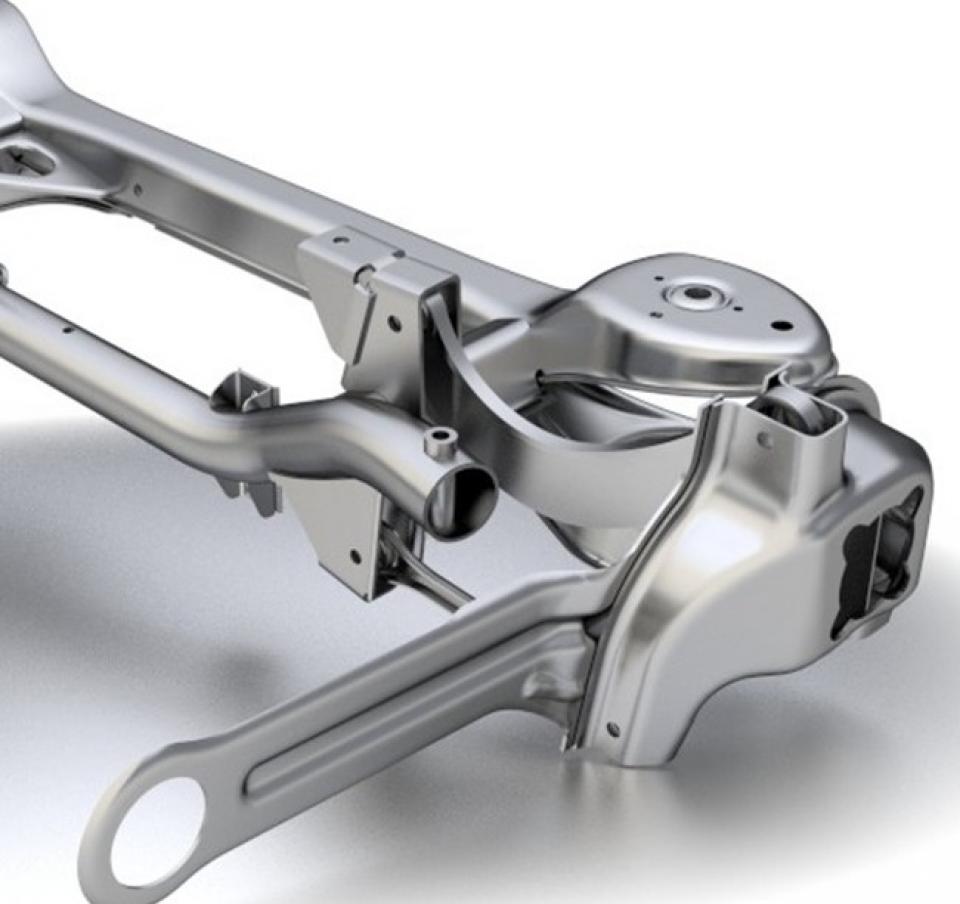

Its high strength and excellent levels of formability - with increased edge ductility and elongation - enable the production of robust components with complex geometry. This supports freedom in design by increasing the lightweighting potential of a part. XPF offers weight savings of over 10% when compared with other AHSS of the same strength, and even more when replacing lower strength steels. XPF steels also provide scope for part consolidation, offering further opportunities for lightweighting and cost savings.

XPF steels can help to improve productivity and increase press shop yields. Their consistently reliable mechanical properties and minimised springback allow improved control of blanking and forming processes for optimised productivity.

XPF's unique and patented concepts result in a robust high-strength steel

Its single phase ferrite matrix with nanoparticipation (800 and 1000 MPa) results in a robust high-strength steel with increased levels of elongation and stretch flangeability compared to equivalent strength materials. These characteristics are important when looking for further lightweighting potential or increased energy absorption.

The highly homogeneous mechanical properties and excellent flatness allow improved control of blanking and forming processes, and tighter tolerances on part geometry. XPF also offers improved roll-forming capability and weldability when compared with equivalent strength complex phase steels.

Versatile steels for chassis, body-in-white and seating

Tata Steel's XPF800 and XPF1000 single-phase, hot-rolled steels offer a superior mix of strength and formability. These versatile steels are suitable for chassis, body-in-white (BIW) and seating applications. Available in the biggest width and thickness range on the market.

Coating

XPF has been developed to support further downgauging of complex parts. This sometimes leads to concerns around corrosion. That is why we are developing a XPF-GI range as well. Please contact us for the latest details.

Slitting blanking and further processing

XPF steels can also be slit and cut to length via our service centre network. High strength, high formality and process ability are also important for tubular applications such as twist beams. Learn more about our tubular offering here.

Our material experts are there to support the deployment of our products in your specific application area. For more information contact our XPF experts.

Are you interested in reducing your total cost of ownership?

XPF steels provide opportunities to reduce total cost of ownership (TCO) through improved productivity and design flexibility, lightweighting and part consolidation.

Tata Steel has developed the TCO Scan, a process to review and quantify how its steel grades perform against objectives of weight, cost and performance. Tata Steel engineers using this method concluded that XPF grades can yield two significant TCO benefits:

- Safer component with increased performance at the same gauge

- Mass reduction at equivalent performance

Rely on our team of material experts to assist you in finding the optimal solution tailored to your specific requirements.

When selecting steel for your chassis part, consider our hot-rolled AHSS product, which provides exceptional manufacturing robustness. Our HyperFlange® brand stands out for its superior edge ductility, high-quality cuting-edges, and various other beneficial features.

For automotive downloads such as brochures, case studies and data sheets, please click below: