Improved formability and strength to achieve manufacturing reliability

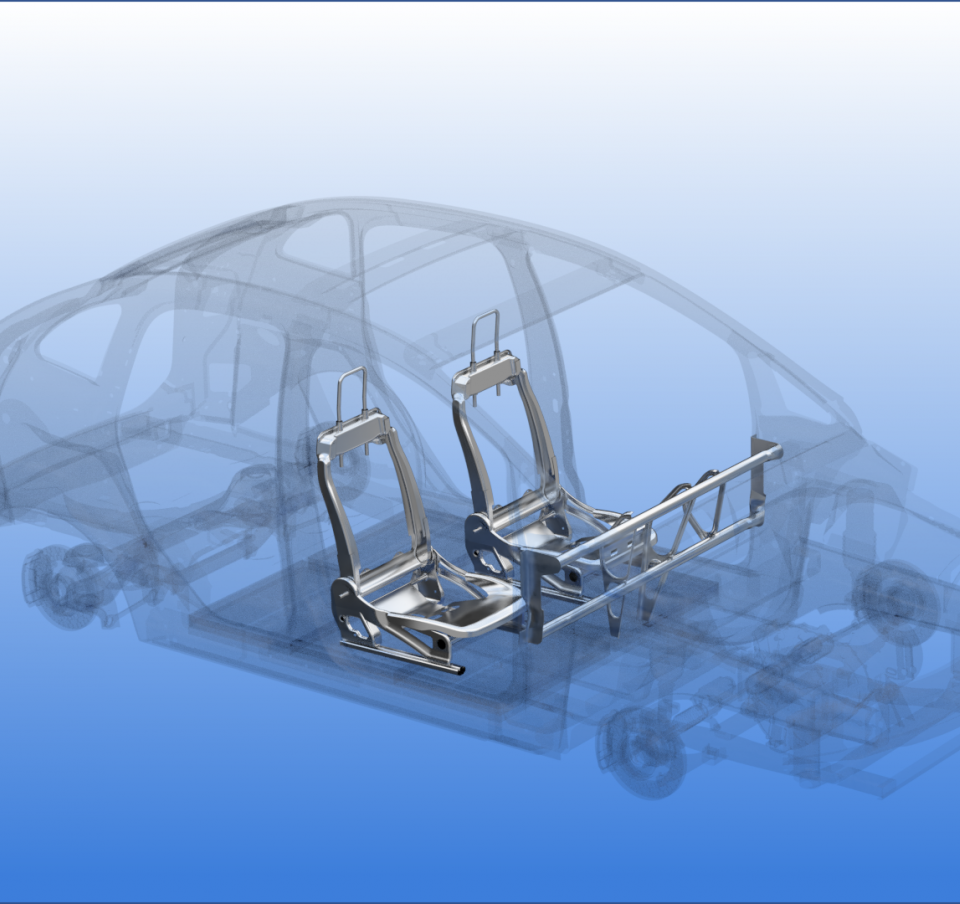

The design of cars is undergoing unprecedented change as a result of emissions legislation and advances in technology enabling autonomous driving. These design changes affect automotive seating and interiors.

Seating manufacturers need steel solutions for their new designs. Tata Steel’s experts can support you to realise the optimum steel solution. Our expertise in steel properties and behaviour in manufacturing and in-use supports optimal grade selection to achieve in-use safety performance, lightweighting and reliable manufacturing of parts.

Unlocking the potential of steel for seating

Our comprehensive range of steels for seating, including advanced high-strength steel (AHSS) and supporting engineering services, offer seating manufacturers:

- Lightweighting opportunities

- Improved processability of demanding parts

- Optimised design for space efficiency

Advanced high-strength steel for lightweighting

Lightweighting to reduce CO2 emissions is a priority in seating design. Tata Steel offers a range of advanced high-strength steels (AHSS) such as thin gauge dual phase steels and thick gauge formability enhanced steels. In the latter category, the XPF family can deliver lightweighting for seating mechanisms and other thicker gauge components.

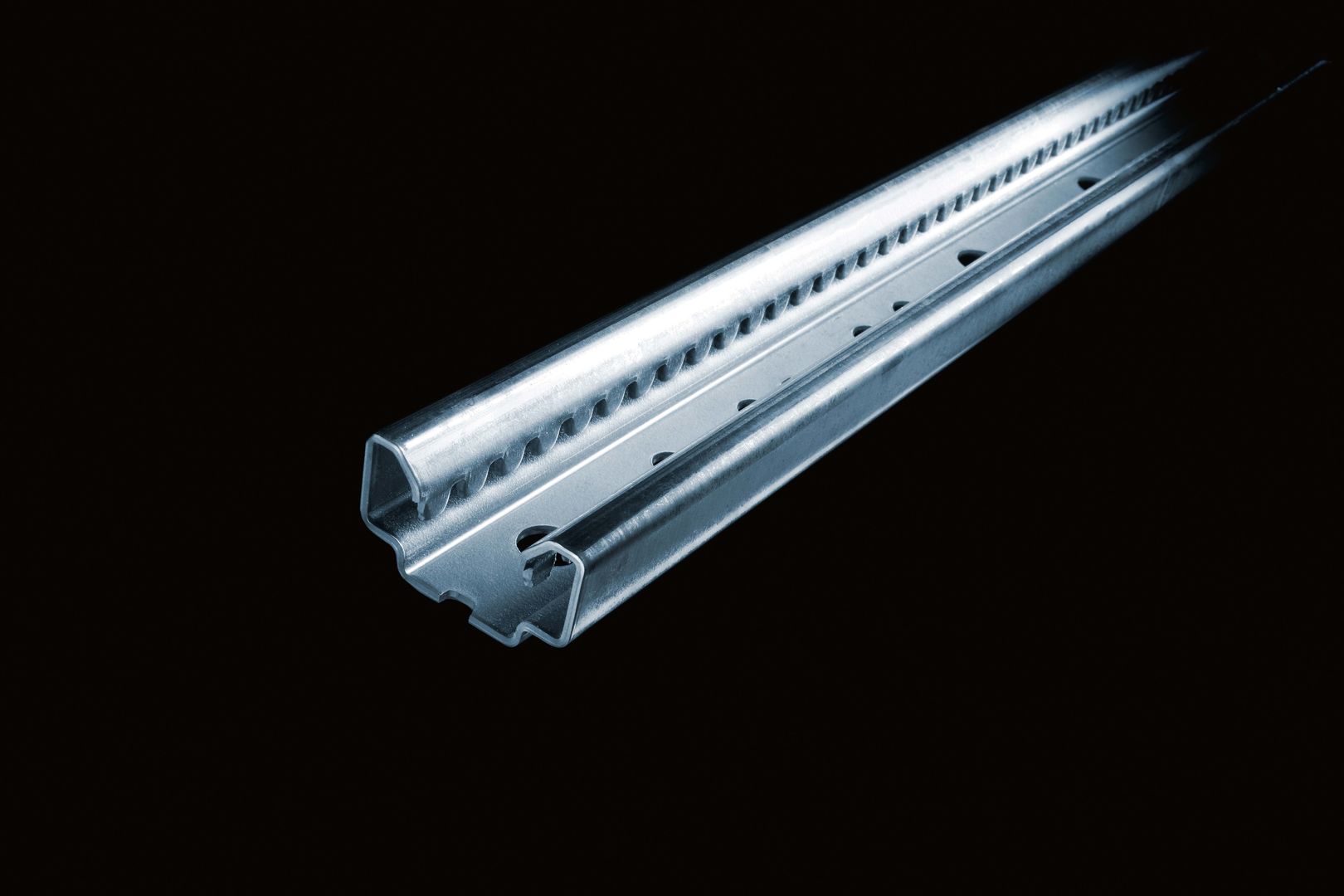

Material selection to improve processing reliability

Consistent manufacturing of components from advanced high-strength steel (AHSS) through deep drawing or with deep collars can be challenging. Our XPF products guarantee both high strength and excellent formability. Along with other important processing parameters such as weldability, they ensure smooth processing of the most challenging parts. Our Ymagine range of direct-rolled products has tight tolerances and consistent quality which ensures reliable processing, making it ideal material for seat tracks.

Space efficient designs enabled by high-strength formable steels

Seating design must be delivered within the constraints of the vehicle package. Electric vehicles have a different floor construction to internal combustion engine vehicles to accommodate the battery packs usually under the floor or located in the tunnel area. These body-in-white changes mean the seat frames need to be more compact but still have the same functionality leading to an increase in the complexity of frame geometry. Our cold-rolled advanced high-strength and ultra high-strength steels (AHSS/UHSS) provide enhanced formability in grades specifically for lightweight seat frames.

A comprehensive portfolio of steel grades for seating

We offer a wide range of hot-rolled (thick gauge), direct-rolled (intermediate gauges) and cold-rolled (thin gauge) steels for seating and interior components in the high-strength steel (HSLA) grades predominantly used in seat frames. Additionally our range of steel grades includes:

- AHSS such as dual phase steels

- uncoated boron steels

- high formability XPF steels

- AHSS and HSLA tubes for seating headrests

- HSLA HC420LA tubes for IP beams

Our material experts are here to support the deployment of our products in seating and interior applications. For more information, contact our seating and interior experts.

Local service centres and direct delivery

We supply steel to customers throughout Europe. We also support customer programmes across the globe. Our steelmaking sites in the Netherlands and the UK are close to major ports – with direct access to a global transport infrastructure. We supply our seating and interior customers:

- Wide coil directly from our mills

- Slit coils and blanks via our steel service centres

- Precision tubes through Tubes/our dedicated automotive service centres

Expertise to optimise your steel design and manufacture

Tata Steel supports the automotive industry with advanced engineering services to fully exploit the benefits of advanced steels. We have extensive seating application knowledge and our services include:

- Aurora materials database with ready-to-run input decks to save hours on CAD simulation preparations

- Value analysis/value engineering to optimise designs for your preferred balance between performance, weight and costs

- Material yield optimisation analysis and recommendations for your press shop

- Life cycle analysis – to determine the impact of material and processing types from material and seat production through to use phase and recycling.

For more information contact our seating experts.

Our materials database, Aurora® Online, gives you fast and easy access to reliable material data. Its comprehensive, up-to-date material files, data sheets and ready-to-run input decks, enable you to set up accurate, reliable simulations.