Easy processing of the toughest materials

Easy to weld

Lean chemistries ensure welding without pre-heating.

| Property | Valast 400 | Valast 450 | Valast 500 |

|---|---|---|---|

| CEV max | 0.42 | 0.45 | 0.50 |

| CET max | 0.30 | 0.33 | 0.37 |

| PCM max | 0.27 | 0.32 | 0.34 |

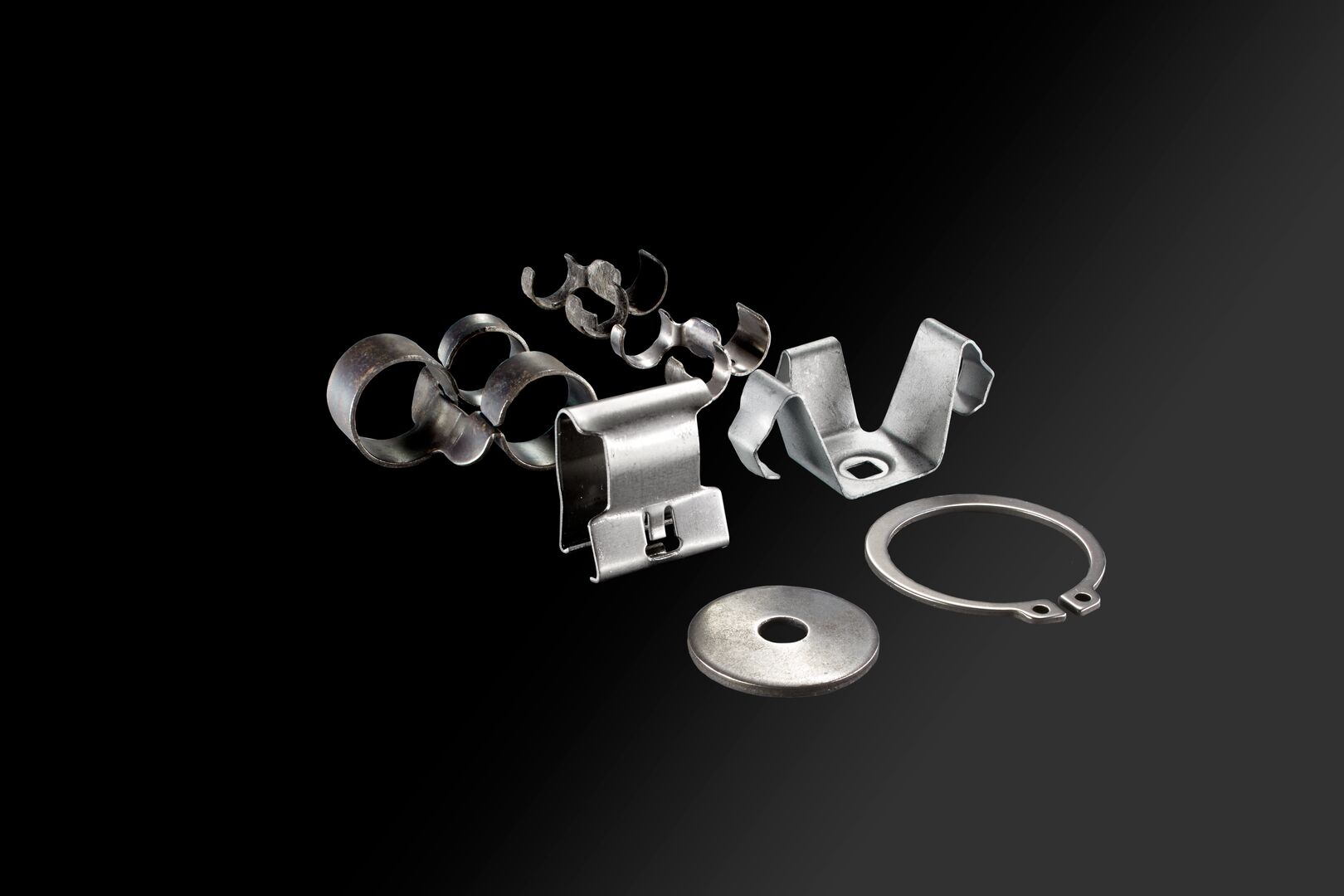

Easy to bend

Bending under tight angles, discover the possibities:

| Property | Valast 400 | Valast 450 | Valast 500 prelim |

|---|---|---|---|

| up to 8 mm | 3 t | 3.5 t | 4 t |

| 8 - 12 mm | 3.5 t | 4.5 t |

Easy and efficient laser cutting

- Benefit from the best steel strip nesting solutions.

- Stress-free over long lengths

- Produce long laser-cut parts without internal stress

Tolerances:

- 1/2 EN on gauge

- Special lengths, widths, shapes, and flatnesses upon request

Built to last, designed to impress

The machines that operate under tough conditions, also show how professional you work. This means they must look as good as they operate.

Tata Steel's Valast combines wear resistance with great surface appearance.

Valast is ideal for paint appearance of tippers and other vehicles with long uniform surfaces.

No pre-treatments are needed to remove surface imperfections or to avoid an orange peel paint effect.

More uniform scale and no surface imperfections

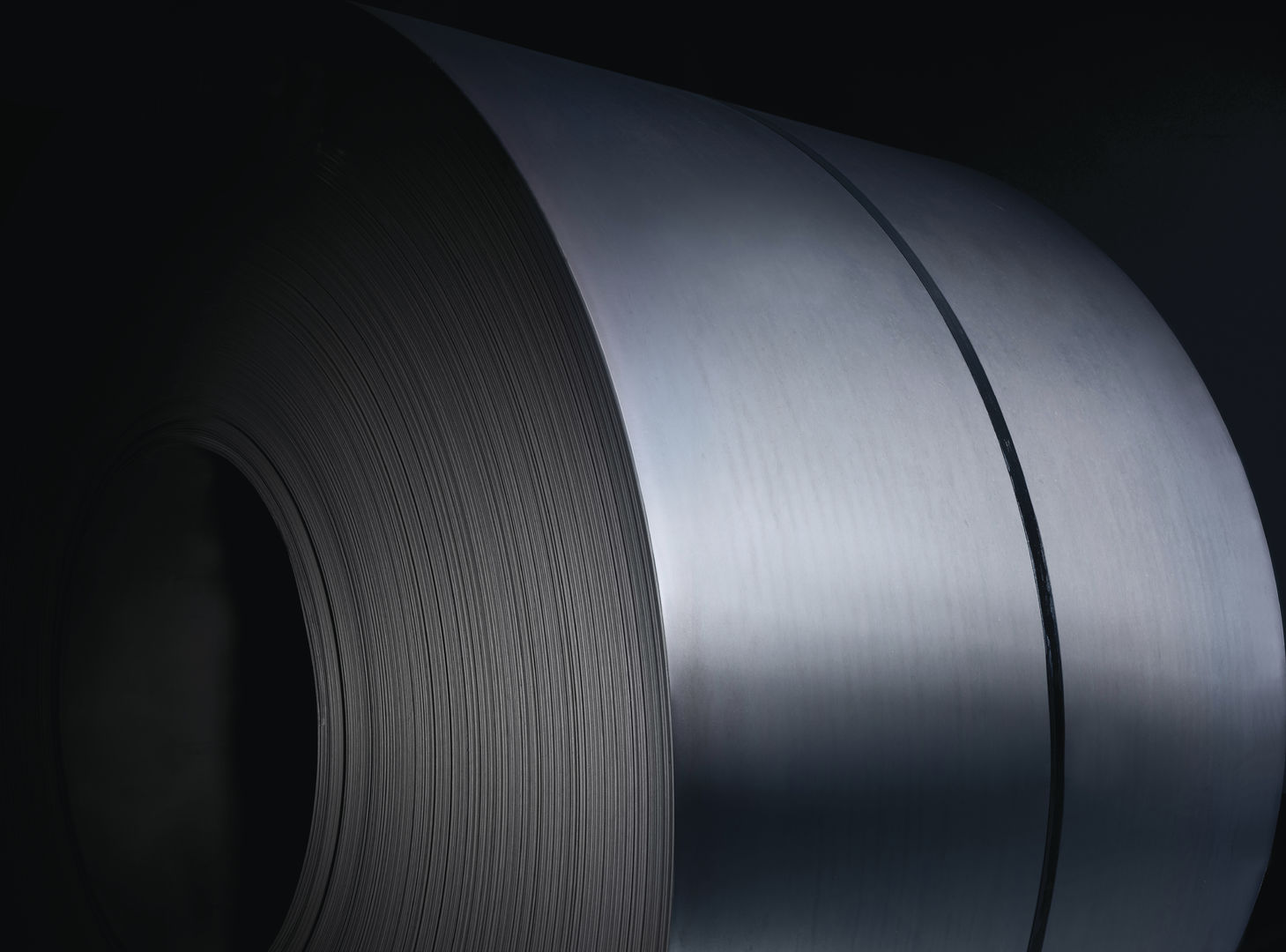

Valast offers a superior surface quality thanks to the uniform scale layer. In any steelmaking process, an oxide layer forms on the surface of the steel. Wear resistant steel is often produced in reversing plate mills and cooled and hardened with water and air. This process creates a thick and uneven scale formation. In contrast, Valast is produced in a hot strip mill, which replaces the quenching method of the reversing mill process with a direct cooling method. This results in a thinner and more homogeneous scale layer. State of art decoiling ensures any remaining uneven scale is removed prior to levelling and cutting the material to its ordered length

Valast is available in 400 - 450 - 500 HB (Brinell hardness) and can be supplied to you in custom sheet lengths and with shorter lead times due to our robust local supply chain.

EN-Engineering-Brochure-Valast

Valast - Brochure

EN-Engineering-Datasheet-Valast 450

Valast 450 - Datasheet

DE-Engineering-Datasheet-Valast 450

Valast 450 - Datasheet (DE)

FR-Engineering-Datasheet-Valast 450

Valast 450 - Datasheet (FR)

EN-Engineering-Datasheet-Valast 400

Valast 400 - Datasheet

DE-Engineering-Datasheet-Valast 400

Valast 400 - Datasheet (DE)

FR-Engineering-Datasheet-Valast 400

Valast 400 - Datasheet (FR)

EN-Engineering-Datasheet-Valast 500

Valast 500 - Datasheet

DE-Engineering-Datenblatt-Valast 500

Valast 500 - Datasheet (DE)

FR-Engineering-Datasheet-Valast 500

Valast 500 - Datasheet (FR)

EN-Engineering-Valast-Scorecard

Valast 450 Strip vs Plate - Scorecard