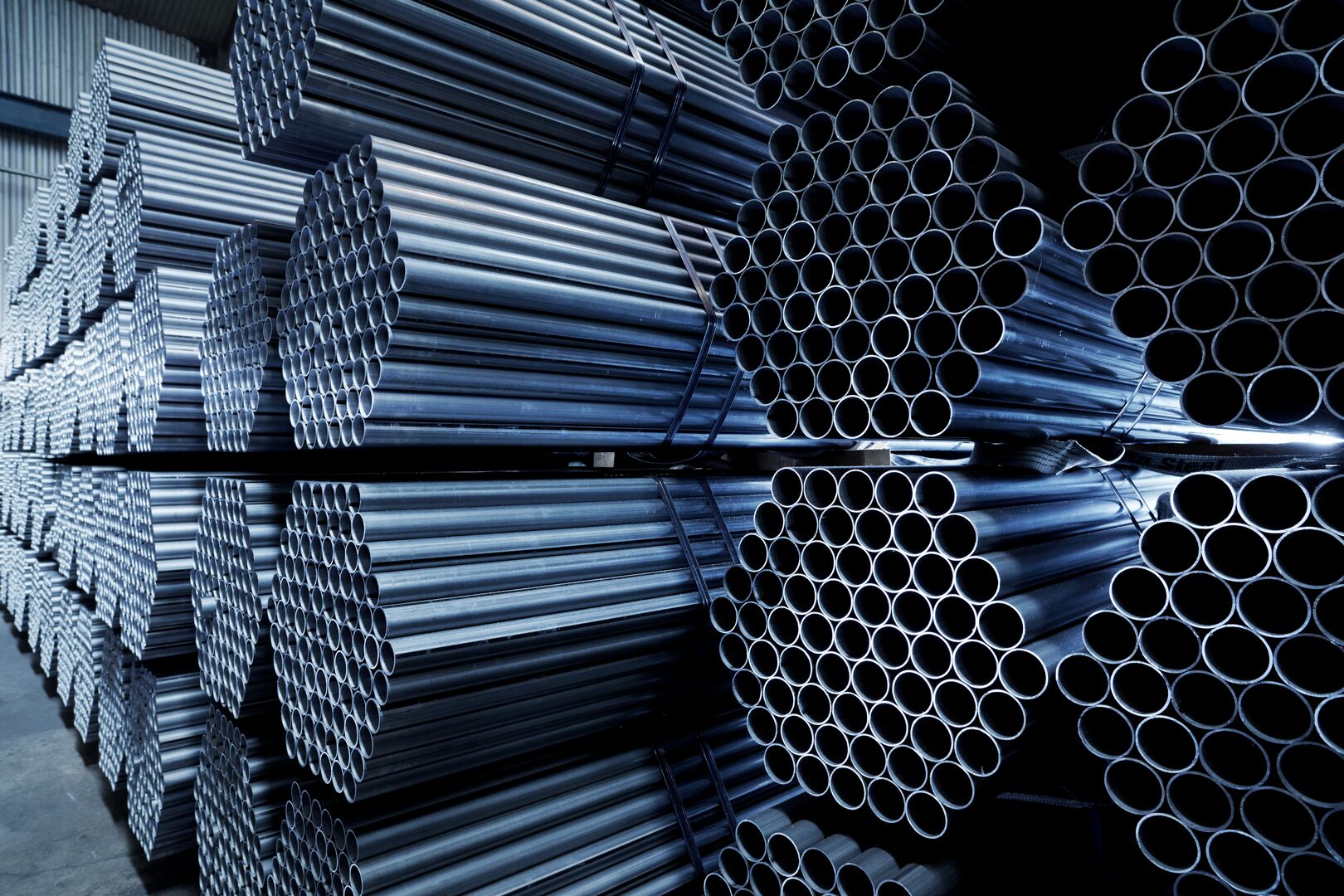

Structural Tubes

Cold formed welded steel structural hollow sections supplied to EN10219.

Produced with precision and expertise, our steel structural hollow sections offer a myriad of benefits for your construction and mechanical needs:

Dimensional consistency and controlled corner radii, excellent weldability even in the corner region, suitability for galvanizing, superior surface quality, batch traceability, etc. Ensuring quality in every piece, the reliable performance of our structural tubes allows you to process and build with confidence.

Our structural tubes are available in high strength qualities up to S700MH enabling strong and lightweight constructions.

EN-Tubes-Structural-Tubes-Forcon-S235JRH

EN-Tubes-Product-Structural-Forcon235-Overview-TSN

Key product features:

• Made with steel from a high quality production process

• Dimensional consistency and corner radius controlled

• High levels of formability and excellent weldability

• Great surface quality

• CE- and UKCA-marked and fully compliant with the Construction Products Regulation (CPR)

• Galvanising category A according to ISO 14713-2:2020

Dimensions:

CHS - Circular 31.8 – 323.9mm

SHS - Square 25x25 – 250x250mm

RHS - Rectangular 30x20 – 300x200mm

Standard lengths are 6m, 12m or 15m - depending on the size and production mill.

Special mill lengths from 4.5m up to 20m can be arranged upon request.

EN-Tubes-Product-Structural-SHS-applications

Building Industry (CE- / UKCA-mark)

- Columns

- Trusses

- Frames

- Piling

- Formwork construction

- Scaffolding

Mechanical Engineering

- Agricultural machinery

- Truck and trailer construction

- Bus construction

- Cranes and construction machinery

- Special vehicles

- Towbars

Renewable energy

- Solar parking

- Solar trackers

EN-Tubes-Product-Structural-SHS-S235JRH Properties TSN

Mechanical Properties

Min. yield strength (MPa) | Tensile strength (MPa) | Min. elongation (%) | impact strength | Carbon equivalent | ||

|---|---|---|---|---|---|---|

| ReH | Rm | L0 = 5,65 √S0 specimen | 10mm x 10mm | (CEV) max | ||

| T≤16mm | T˂3mm | 3mm≤T≤40mm | T≤40mm | °C | J | |

| 235 | 360-510 | 360-510 | 24 | +20 | 27 | 0.35 |

For wall thicknesses >3mm and section sizes D/T<15 (circular) and (B+H)/2T<12.5 (square/rectangular) min elongation is reduced by 2%.

Chemical composition % by mass

C | Si | Mn | P | S |

|---|---|---|---|---|

| max | max | max | max | max |

| 0.17 | - | 1.40 | 0.040 | 0.040 |

EN-Tubes-Product-Structural-SHS-Tolerances TSN

Circular, square and rectangular hollow sections with tolerances according to EN10219-2.

Our hollow sections are also available in the product version TT with tighter tolerances

Characteristic | Circular | Square/Rectangular | |

|---|---|---|---|

| Outside dimensions (D, B and H) | ±1% with a minimum of ±0.5mm | Side length (mm) H,B<100mm 100mm≤H,B≤200mm H,B>200mm | Tolerance ±1% with a minimum of ±0.5mm ±0.8% ±0.6% |

| Thickness (T) | For D≤ 406.4mm For D≤ 406.4mm | T≤5mm

T>5mm | ±10%

±0.50mm

|

| Out of roundness (O) | 2% for D/T<100, where D/T≥100 out-of-roundness tolerance to be agreed | - | |

Concavity/convexity (independent tolerance on outside dimensions) | - |

±0.8% with a minimum of 0.5mm | |

| Squareness of side | - | 90° ±1° | |

External corner profile (radius need to be tangential to the sides) EN10219: Part 2 Table 3 | T≤6.0mm T>10.0mm | 1.6T to 2.4T 2.0T to 3.0T 2.4T to 3.6T | |

| Twist (V) | - | 2mm plus 0.5mm/m length | |

| Straightness | 0.20% of total length and 3mm over any 1m length | 0.15% of total length and 3mm over any 1m length | |

| Mass (M) | ±6% on individual lengths | ±6% on individual lengths | |

| Length | -0 +50mm | -0 +50mm | |

EN-Tubes-Product-Structural-Forcon-235-Supply conditions-TSN

Certification:

2.2 test report according to EN10204

CE-marking in compliance with the European Construction Products Regulation (CPR EU)

UKCA-marking in compliance with the UK Construction Products Regulation (CPR UK)

Our structural hollow sections are also available as Tailored Tubes Forcon®TT with several extras customised to your needs.

EN-Tubes-Product-Structural-Forcon-Available Extras-TSN

Forcon® TT is a customised cold formed welded structural hollow section.

You can choose from several extras such as

- different weld seam options

- tighter dimensional tolerances

- an improved surface finish

- a bespoke chemical composition

- exact lengths

- extra testing

- special packaging

We are happy to explore how we can meet your specific requirements with our Tailored Tube options.

Please get in touch.

- Zeremis® Carbon Lite: Our low carbon emission steel solution offering the potential for up to 90% reduction in CO2 intensity.

For hollow sections according to EN10210 please visit Celsius® hot finished hollow sections | Tata Steel UK

EN-Tubes-Product-Structural-Forcon-235-Downloads-TSN

Documents for S235

The brochure and datasheets are also available in Dutch, German or French.

Please get in touch if you would like to receive them.

EN-Tubes-Product-Structural-ForconTT-Datasheet-InternalScarfing-TSN

Datasheet Forcon®TT Internal Scarfing

EN-Tubes-Product-Structural-Forcon-DoP-S235JRH-2.2cert-TSN

DoP - Declaration of Performance Forcon® 235

EN-Tubes-Product-Structural-ForconTT-DoP-S235JRH-2.2cert-TSN

DoP – Declaration of Performance Forcon®TT 235 with 2.2 certificate

EN-Tubes-Product-Structural-ForconTT-DoP-S235JRH-3.1cert-TSN

DoP – Declaration of Performance Forcon®TT 235 with 3.1 certificate

EN-ConstructionEngineering-Download-EPD-Tata Steel Structural hollow sections

EPD Forcon structural hollow sections

EN-Tubes-Structural-Tubes-Forcon-S275J0H/J2H

EN-Tubes-Product-Structural-Forcon235-Overview-TSN

Key product features:

• Made with steel from a high quality production process

• Dimensional consistency and corner radius controlled

• High levels of formability and excellent weldability

• Great surface quality

• CE- and UKCA-marked and fully compliant with the Construction Products Regulation (CPR)

• Galvanising category A according to ISO 14713-2:2020

Dimensions:

CHS - Circular 31.8 – 323.9mm

SHS - Square 25x25 – 250x250mm

RHS - Rectangular 30x20 – 300x200mm

Standard lengths are 6m, 12m or 15m - depending on the size and production mill.

Special mill lengths from 4.5m up to 20m can be arranged upon request.

EN-Tubes-Product-Structural-SHS-applications

Building Industry (CE- / UKCA-mark)

- Columns

- Trusses

- Frames

- Piling

- Formwork construction

- Scaffolding

Mechanical Engineering

- Agricultural machinery

- Truck and trailer construction

- Bus construction

- Cranes and construction machinery

- Special vehicles

- Towbars

Renewable energy

- Solar parking

- Solar trackers

EN-Tubes-Product-Structural-SHS-275 Properties TSN

Mechanical Properties

Min. yield strength (MPa) | Tensile strength (MPa) | Elongation (%) min | impact strength | Carbon equivalent | ||

|---|---|---|---|---|---|---|

| ReH min N/mm2 | Rm min N/mm2 | L0 = 5,65 √S0 specimen | 10mm x 10mm | (CEV) max | ||

| T≤16mm | T˂3mm | 3mm≤T≤40mm | T≤40mm | °C | J | |

| 275 | 430-580 | 410-560 | 20 | 0 | 27 | 0.40 |

For section sizes D/T<15 (circular) and (B+H)/2T<12.5 (square/rectangular) the minimum elongation is reduced by 2%.

Chemical composition % by mass

C | Si | Mn | P | S |

|---|---|---|---|---|

| 0.20 | - | 1.50 | 0.035 | 0.035 |

EN-Tubes-Product-Structural-SHS-Tolerances TSN

Circular, square and rectangular hollow sections with tolerances according to EN10219-2.

Our hollow sections are also available in the product version TT with tighter tolerances

Characteristic | Circular | Square/Rectangular | |

|---|---|---|---|

| Outside dimensions (D, B and H) | ±1% with a minimum of ±0.5mm | Side length (mm) H,B<100mm 100mm≤H,B≤200mm H,B>200mm | Tolerance ±1% with a minimum of ±0.5mm ±0.8% ±0.6% |

| Thickness (T) | For D≤ 406.4mm For D≤ 406.4mm | T≤5mm

T>5mm | ±10%

±0.50mm

|

| Out of roundness (O) | 2% for D/T<100, where D/T≥100 out-of-roundness tolerance to be agreed | - | |

Concavity/convexity (independent tolerance on outside dimensions) | - |

±0.8% with a minimum of 0.5mm | |

| Squareness of side | - | 90° ±1° | |

External corner profile (radius need to be tangential to the sides) EN10219: Part 2 Table 3 | T≤6.0mm T>10.0mm | 1.6T to 2.4T 2.0T to 3.0T 2.4T to 3.6T | |

| Twist (V) | - | 2mm plus 0.5mm/m length | |

| Straightness | 0.20% of total length and 3mm over any 1m length | 0.15% of total length and 3mm over any 1m length | |

| Mass (M) | ±6% on individual lengths | ±6% on individual lengths | |

| Length | -0 +50mm | -0 +50mm | |

EN-Tubes-Product-Structural-Forcon-275-Supply conditions-TSN

Certification:

S275J0H with 2.2 test report and S275J2H with 3.1 inspection certificate according to EN10204

CE-marking in compliance with the European Construction Products Regulation (CPR EU)

UKCA-marking in compliance with the UK Construction Products Regulation (CPR UK)

Our structural hollow sections are also available as Tailored Tubes Forcon®TT with several extras customised to your needs.

EN-Tubes-Product-Structural-Forcon-Available Extras-TSN

Forcon® TT is a customised cold formed welded structural hollow section.

You can choose from several extras such as

- different weld seam options

- tighter dimensional tolerances

- an improved surface finish

- a bespoke chemical composition

- exact lengths

- extra testing

- special packaging

We are happy to explore how we can meet your specific requirements with our Tailored Tube options.

Please get in touch.

- Zeremis® Carbon Lite: Our low carbon emission steel solution offering the potential for up to 90% reduction in CO2 intensity.

For hollow sections according to EN10210 please visit Celsius® hot finished hollow sections | Tata Steel UK

EN-Tubes-Product-Structural-Forcon-275-Downloads-TSN

Documents for S275

The brochure and datasheets are also available in Dutch, German or French.

Please get in touch if you would like to receive them.

EN-Tubes-Product-Structural-ForconTT-Datasheet-InternalScarfing-TSN

Datasheet Forcon®TT Internal Scarfing

EN-Tubes-Product-Structural-Forcon-DoP-S275J0H-2.2cert-TSN

DoP - Declaration of Performance Forcon® 275J0H

EN-Tubes-Product-Structural-Forcon-DoP-S275J2H-3.1cert-TSN

DoP - Declaration of Performance Forcon® 275J2H

EN-Tubes-Product-Structural-ForconTT-DoP-S275J0H-2.2cert-TSN

DoP – Declaration of Performance Forcon®TT 275J0H with 2.2 certificate

EN-Tubes-Product-Structural-ForconTT-DoP-S275J0H-3.1cert-TSN

DoP – Declaration of Performance Forcon®TT 275J0H with 3.1 certificate

EN-Tubes-Product-Structural-ForconTT-DoP-S275J2H-TSN

DoP – Declaration of Performance Forcon®TT 275J2H

EN-ConstructionEngineering-Download-EPD-Tata Steel Structural hollow sections

EPD Forcon structural hollow sections

EN-Tubes-Structural-Tubes-Forcon-S355J2H

EN-Tubes-Product-Structural-Forcon355-Overview-TSN

Key product features:

• Made with steel from a high quality production process

• Dimensional consistency and corner radius controlled

• High levels of formability and excellent weldability

• Great surface quality

• CE- and UKCA-marked and fully compliant with the Construction Products Regulation (CPR)

• Galvanising category A or B according to ISO 14713-2:2020

Dimensions:

CHS - Circular 31.8 – 323.9mm

SHS - Square 25x25 – 250x250mm

RHS - Rectangular 30x20 – 300x200mm

Standard lengths are 6m, 12m or 15m - depending on the size and production mill.

Special mill lengths from 4.5m up to 20m can be arranged upon request.

EN-Tubes-Product-Structural-SHS-applications

Building Industry (CE- / UKCA-mark)

- Columns

- Trusses

- Frames

- Piling

- Formwork construction

- Scaffolding

Mechanical Engineering

- Agricultural machinery

- Truck and trailer construction

- Bus construction

- Cranes and construction machinery

- Special vehicles

- Towbars

Renewable energy

- Solar parking

- Solar trackers

EN-Tubes-Product-Structural-SHS-S355J2H-Properties TSN

Mechanical Properties

Min. yield strength (MPa) | Tensile strength (MPa) | Min. elongation (%) | Impact strength | Carbon equivalent | ||

|---|---|---|---|---|---|---|

| ReH min N/mm2 | Rm min N/mm2 | L0 = 5,65 √S0 specimen | 10mm x 10mm | (CEV) max | ||

| T≤16mm | T˂3mm | 3mm≤T≤40mm | T ≤ 40mm | °C | J | |

| 355 | 510 - 680 | 470 - 630 | 20 | -20 | 27 | 0.45 |

For section sizes D/T<15 (circular) and (B+H)/2T< 12.5 (square/rectangular) minimum elongation is reduced by 2%.

Chemical composition % by mass

C | Si | Mn | P | S |

|---|---|---|---|---|

| 0.22 | 0.55 | 1.60 | 0.030 | 0.030 |

EN-Tubes-Product-Structural-SHS-Tolerances TSN

Circular, square and rectangular hollow sections with tolerances according to EN10219-2.

Our hollow sections are also available in the product version TT with tighter tolerances

Characteristic | Circular | Square/Rectangular | |

|---|---|---|---|

| Outside dimensions (D, B and H) | ±1% with a minimum of ±0.5mm | Side length (mm) H,B<100mm 100mm≤H,B≤200mm H,B>200mm | Tolerance ±1% with a minimum of ±0.5mm ±0.8% ±0.6% |

| Thickness (T) | For D≤ 406.4mm For D≤ 406.4mm | T≤5mm

T>5mm | ±10%

±0.50mm

|

| Out of roundness (O) | 2% for D/T<100, where D/T≥100 out-of-roundness tolerance to be agreed | - | |

Concavity/convexity (independent tolerance on outside dimensions) | - |

±0.8% with a minimum of 0.5mm | |

| Squareness of side | - | 90° ±1° | |

External corner profile (radius need to be tangential to the sides) EN10219: Part 2 Table 3 | T≤6.0mm T>10.0mm | 1.6T to 2.4T 2.0T to 3.0T 2.4T to 3.6T | |

| Twist (V) | - | 2mm plus 0.5mm/m length | |

| Straightness | 0.20% of total length and 3mm over any 1m length | 0.15% of total length and 3mm over any 1m length | |

| Mass (M) | ±6% on individual lengths | ±6% on individual lengths | |

| Length | -0 +50mm | -0 +50mm | |

EN-Tubes-Product-Structural-Forcon-355-Supply conditions-TSN

Certification:

3.1 inspection certificate according to EN10204

CE-marking in compliance with the European Construction Products Regulation (CPR EU)

UKCA-marking in compliance with the UK Construction Products Regulation (CPR UK)

Our structural hollow sections are also available as Tailored Tubes Forcon®TT with several extras customised to your needs.

EN-Tubes-Product-Structural-Forcon-Available Extras-TSN

Forcon® TT is a customised cold formed welded structural hollow section.

You can choose from several extras such as

- different weld seam options

- tighter dimensional tolerances

- an improved surface finish

- a bespoke chemical composition

- exact lengths

- extra testing

- special packaging

We are happy to explore how we can meet your specific requirements with our Tailored Tube options.

Please get in touch.

- Zeremis® Carbon Lite: Our low carbon emission steel solution offering the potential for up to 90% reduction in CO2 intensity.

For hollow sections according to EN10210 please visit Celsius® hot finished hollow sections | Tata Steel UK

EN-Tubes-Product-Structural-Forcon-355-Downloads-TSN

Documents for S355

The brochure and datasheets are also available in Dutch, German or French.

Please get in touch if you would like to receive them.

EN-Tubes-Product-Structural-ForconTT-Datasheet-InternalScarfing-TSN

Datasheet Forcon®TT Internal Scarfing

EN-Tubes-Product-Structural-Forcon-DoP-S355J2H-TSN

DoP - Declaration of Performance Forcon® 355

EN-Tubes-Product-Structural-ForconTT-DoP-S355J0H-TSN

DoP – Declaration of Performance Forcon®TT 355J0H

EN-Tubes-Product-Structural-ForconTT-DoP-S355J2H-TSN

DoP – Declaration of Performance Forcon®TT 355J2H

EN-Tubes-Product-Structural-ForconTT-DoP-S355K2H-TSN

DoP – Declaration of Performance Forcon®TT 355K2H

EN-Tubes-Product-Structural-ForconTT-DoP-S355MH-TSN

DoP – Declaration of Performance Forcon®TT 355MH

EN-Tubes-Product-Structural-ForconTT-DoP-S355MLH-TSN

DoP – Declaration of Performance Forcon®TT 355MLH

EN-ConstructionEngineering-Download-EPD-Tata Steel Structural hollow sections

EPD Forcon structural hollow sections

EN-Tubes-Structural-Tubes-Forcon-S500MH

EN-Tubes-Product-Structural-Forcon500-Overview-TSN

Key product features:

• Made with steel from a high quality production process

• Dimensional consistency and corner radius controlled

• High levels of formability and excellent weldability

• Great surface quality

• Galvanising category A according to ISO 14713-2:2020

Dimensions:

CHS - Circular 31.8 – 323.9mm

SHS - Square 25x25 – 250x250mm

RHS - Rectangular 30x20 – 300x200mm

Standard lengths are 6m, 12m or 15m - depending on the size and production mill.

Special mill lengths from 4.5m up to 20m can be arranged upon request.

EN-Tubes-Product-Structural-SHS-applications

Building Industry (CE- / UKCA-mark)

- Columns

- Trusses

- Frames

- Piling

- Formwork construction

- Scaffolding

Mechanical Engineering

- Agricultural machinery

- Truck and trailer construction

- Bus construction

- Cranes and construction machinery

- Special vehicles

- Towbars

Renewable energy

- Solar parking

- Solar trackers

EN-Tubes-Product-Structural-SHS-S500MH-Properties TSN

Mechanical Properties

Min. yield strength (MPa) | Tensile strength (MPa) | Min. elongation (%) | Min Impact energy KV2 (J) | ||

|---|---|---|---|---|---|

| A | at test temperature of -20°C | ||||

ReH |

| A long | A trans | Long | Trans |

500 | 580 - 760 | 11 | 9 | 40 | 20 |

For thicknesses ≥ 3mm; for section sizes D/T ≤ 10 (square and rectangular) the minimum elongation is reduced by 4 and the maximum tensile strength increased by 50 Mpa. For section sizes D/T> 10 to < 15 (square and rectangular) the minimum elongation is reduced by 2 and the maximum tensile strenght increased by 50 Mpa. For thicknesses < 3mm values shall be agreed between the purchaser and manufacturer.

Chemical composition % by mass.

C | Si | Mn | P | S | Cr | Mo | Ni | Aitot | Cu | Nb | Ti | V | N | CEV |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| max | max | max | max | max | max | max | max | max | max | max | max | max | max | max |

| 0.16 | 0.6 | 1.7 | 0.02 | 0.02 | 0.3 | 0.2 | 0.8 | 0.02 | 0.55 | 0.09 | 0.06 | 0.12 | 0.025 | 0.4 |

CEV exceeds the requirements of EN102219-3:2020; CEV= C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

EN-Tubes-Product-Structural-SHS-Tolerances TSN

Circular, square and rectangular hollow sections with tolerances according to EN10219-2.

Our hollow sections are also available in the product version TT with tighter tolerances

Characteristic | Circular | Square/Rectangular | |

|---|---|---|---|

| Outside dimensions (D, B and H) | ±1% with a minimum of ±0.5mm | Side length (mm) H,B<100mm 100mm≤H,B≤200mm H,B>200mm | Tolerance ±1% with a minimum of ±0.5mm ±0.8% ±0.6% |

| Thickness (T) | For D≤ 406.4mm For D≤ 406.4mm | T≤5mm

T>5mm | ±10%

±0.50mm

|

| Out of roundness (O) | 2% for D/T<100, where D/T≥100 out-of-roundness tolerance to be agreed | - | |

Concavity/convexity (independent tolerance on outside dimensions) | - |

±0.8% with a minimum of 0.5mm | |

| Squareness of side | - | 90° ±1° | |

External corner profile (radius need to be tangential to the sides) EN10219: Part 2 Table 3 | T≤6.0mm T>10.0mm | 1.6T to 2.4T 2.0T to 3.0T 2.4T to 3.6T | |

| Twist (V) | - | 2mm plus 0.5mm/m length | |

| Straightness | 0.20% of total length and 3mm over any 1m length | 0.15% of total length and 3mm over any 1m length | |

| Mass (M) | ±6% on individual lengths | ±6% on individual lengths | |

| Length | -0 +50mm | -0 +50mm | |

EN-Tubes-Product-Structural-Forcon-500/600/700-Supply conditions-TSN

Certification:

3.1 inspection certificate according to EN10204

Our structural hollow sections are also available as Tailored Tubes Forcon®TT with several extras customised to your needs.

EN-Tubes-Product-Structural-Forcon-Available Extras-TSN

Forcon® TT is a customised cold formed welded structural hollow section.

You can choose from several extras such as

- different weld seam options

- tighter dimensional tolerances

- an improved surface finish

- a bespoke chemical composition

- exact lengths

- extra testing

- special packaging

We are happy to explore how we can meet your specific requirements with our Tailored Tube options.

Please get in touch.

- Zeremis® Carbon Lite: Our low carbon emission steel solution offering the potential for up to 90% reduction in CO2 intensity.

For hollow sections according to EN10210 please visit Celsius® hot finished hollow sections | Tata Steel UK

EN-Tubes-Product-Structural-Forcon-500/600/700-Downloads-TSN

Documents for high strength steel

The brochure and datasheets are also available in Dutch, German or French.

Please get in touch if you would like to receive them.

EN-Tubes-Product-Structural-ForconTT-Datasheet-InternalScarfing-TSN

Datasheet Forcon®TT Internal Scarfing

EN-ConstructionEngineering-Download-EPD-Tata Steel Structural hollow sections

EPD Forcon structural hollow sections

EN-Tubes-Structural-Tubes-Forcon-S600MH

EN-Tubes-Product-Structural-Forcon600-Overview-TSN

Key product features:

• Made with steel from a high quality production process

• Dimensional consistency and corner radius controlled

• High levels of formability and excellent weldability

• Great surface quality

• Galvanising category A according to ISO 14713-2:2020

Dimensions:

CHS - Circular 31.8 – 193.7mm

SHS - Square 25x25 – 160x160mm

RHS - Rectangular 30x20 – 200x120mm

Standard lengths are 6m, 12m or 15m - depending on the size and production mill.

Special mill lengths from 4.5m up to 20m can be arranged upon request.

EN-Tubes-Product-Structural-SHS-applications

Building Industry (CE- / UKCA-mark)

- Columns

- Trusses

- Frames

- Piling

- Formwork construction

- Scaffolding

Mechanical Engineering

- Agricultural machinery

- Truck and trailer construction

- Bus construction

- Cranes and construction machinery

- Special vehicles

- Towbars

Renewable energy

- Solar parking

- Solar trackers

EN-Tubes-Product-Structural-SHS-S600MH-Properties TSN

Mechanical Properties

Min. yield strength (MPa) | Tensile strength (MPa) | Min. elongation (%) | Min Impact energy KV2 (J) | ||

|---|---|---|---|---|---|

| at test temperature of -20°C | |||||

ReH | Rm | A long | A trans | Long | Trans |

600 | 650 - 820 | 9 | 7 | 27 | 16 |

For thicknesses ≥ 3mm; for section sizes D/T ≤ 10 (circular) and (B+H)/2T ≤ 10 (square and rectangular) the minimum elongation is reduced by 4 and the maximum tensile strength increased by 50 Mpa. For section sizes D/T > 10 to < 15 (circular) and (B+H)/2T >10 to <15 (square and rectangular) the minimum elongation is reduced by 2 and the maximum tensile strenght increased by 50 Mpa. For thicknesses < 3mm values shall be agreed between the purchaser and manufacturer.

Chemical composition % by mass.

C | Si | Mn | P | S | Cr | Mo | Ni | Aitot | Cu | Nb | Ti | V | N | CEV |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| max | max | max | max | max | max | max | max | max | max | max | max | max | max | max |

| 0.16 | 0.60 | 1.90 | 0.020 | 0.015 | 0.30 | 0.50 | 0.80 | 0.015 | 0.55 | 0.090 | 0.22 | 0.20 | 0.025 | 0.40 |

CEV exceeds the requirements of EN10219-3:2020; CEV = C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

EN-Tubes-Product-Structural-SHS-Tolerances TSN

Circular, square and rectangular hollow sections with tolerances according to EN10219-2.

Our hollow sections are also available in the product version TT with tighter tolerances

Characteristic | Circular | Square/Rectangular | |

|---|---|---|---|

| Outside dimensions (D, B and H) | ±1% with a minimum of ±0.5mm | Side length (mm) H,B<100mm 100mm≤H,B≤200mm H,B>200mm | Tolerance ±1% with a minimum of ±0.5mm ±0.8% ±0.6% |

| Thickness (T) | For D≤ 406.4mm For D≤ 406.4mm | T≤5mm

T>5mm | ±10%

±0.50mm

|

| Out of roundness (O) | 2% for D/T<100, where D/T≥100 out-of-roundness tolerance to be agreed | - | |

Concavity/convexity (independent tolerance on outside dimensions) | - |

±0.8% with a minimum of 0.5mm | |

| Squareness of side | - | 90° ±1° | |

External corner profile (radius need to be tangential to the sides) EN10219: Part 2 Table 3 | T≤6.0mm T>10.0mm | 1.6T to 2.4T 2.0T to 3.0T 2.4T to 3.6T | |

| Twist (V) | - | 2mm plus 0.5mm/m length | |

| Straightness | 0.20% of total length and 3mm over any 1m length | 0.15% of total length and 3mm over any 1m length | |

| Mass (M) | ±6% on individual lengths | ±6% on individual lengths | |

| Length | -0 +50mm | -0 +50mm | |

EN-Tubes-Product-Structural-Forcon-500/600/700-Supply conditions-TSN

Certification:

3.1 inspection certificate according to EN10204

Our structural hollow sections are also available as Tailored Tubes Forcon®TT with several extras customised to your needs.

EN-Tubes-Product-Structural-Forcon-Available Extras-TSN

Forcon® TT is a customised cold formed welded structural hollow section.

You can choose from several extras such as

- different weld seam options

- tighter dimensional tolerances

- an improved surface finish

- a bespoke chemical composition

- exact lengths

- extra testing

- special packaging

We are happy to explore how we can meet your specific requirements with our Tailored Tube options.

Please get in touch.

- Zeremis® Carbon Lite: Our low carbon emission steel solution offering the potential for up to 90% reduction in CO2 intensity.

For hollow sections according to EN10210 please visit Celsius® hot finished hollow sections | Tata Steel UK

EN-Tubes-Product-Structural-Forcon-500/600/700-Downloads-TSN

Documents for high strength steel

The brochure and datasheets are also available in Dutch, German or French.

Please get in touch if you would like to receive them.

EN-Tubes-Product-Structural-ForconTT-Datasheet-InternalScarfing-TSN

Datasheet Forcon®TT Internal Scarfing

EN-ConstructionEngineering-Download-EPD-Tata Steel Structural hollow sections

EPD Forcon structural hollow sections

EN-Tubes-Structural-Tubes-Forcon-S700MH

EN-Tubes-Product-Structural-Forcon700-Overview-TSN

Key product features:

• Made with steel from a high quality production process

• Dimensional consistency and corner radius controlled

• High levels of formability and excellent weldability

• Great surface quality

• Galvanising category C according to ISO 14713-2:2020

Dimensions:

CHS - Circular 31.8 – 127mm

SHS - Square 25x25 – 100x100mm

RHS - Rectangular 30x20 – 140x60mm

Standard lengths are 6m, 12m or 15m - depending on the size and production mill.

Special mill lengths from 4.5m up to 20m can be arranged upon request.

EN-Tubes-Product-Structural-SHS-applications

Building Industry (CE- / UKCA-mark)

- Columns

- Trusses

- Frames

- Piling

- Formwork construction

- Scaffolding

Mechanical Engineering

- Agricultural machinery

- Truck and trailer construction

- Bus construction

- Cranes and construction machinery

- Special vehicles

- Towbars

Renewable energy

- Solar parking

- Solar trackers

EN-Tubes-Product-Structural-SHS-S700MH-Properties TSN

Mechanical Properties

Min. yield strength (MPa) | Tensile strength (MPa) | Min. elongation (%) | Min Impact energy KV2 (J) | ||

|---|---|---|---|---|---|

| at test temperature of -20°C | |||||

ReH | Rm | A long | A trans | Long | Trans |

700 | 750 - 950 | 7 | 5 | 27 | 16 |

For thicknesses ≥ 3mm; for section sizes D/T ≤ 10 (circular) and (B+H)/2T ≤ 10 (square and rectangular) the minimum elongation is reduced by 4 and the maximum tensile strength increased by 50 Mpa. For section sizes D/T > 10 to < 15 (circular) and (B+H)/2T >10 to <15 (square and rectangular) the minimum elongation is reduced by 2 and the maximum tensile strength increased by 50 Mpa. For thicknesses < 3mm values shall be agreed between the purchaser and manufacturer.

Chemical composition % by mass.

C | Si | Mn | P | S | Cr | Mo | Ni | Aitot | Cu | Nb | Ti | V | N | CEV |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| max | max | max | max | max | max | max | max | max | max | max | max | max | max | max |

| 0.16 | 0.60 | 2.1 | 0.02 | 0.015 | 0.3 | 0.5 | 0.8 | 0.015 | 0.55 | 0.09 | 0.22 | 0.2 | 0.025 | 0.42 |

CEV exceeds the requirements of EN10219-3:2020; CEV = C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

EN-Tubes-Product-Structural-SHS-275 Tolerances TSN

Our structural hollow sections are manufactured to the tolerances defined in EN 10219: Part 2.

Tighter tolerances are available on request and if you require specific tolerances in excess of this, please contact us.

Characteristic | Circular | Square/Rectangular |

|---|---|---|

| Outside dimensions (D, B and H) | ±1% with a minimum of ±0.5mm | H,B<100mm ±1% with a minimum of ±0.5mm 100mm≤H,B≤200mm ±0.8% H,B>200mm ±0.6% |

| Thickness (T) | T≤5mm ±10% T>5mm ±0.50mm | T≤5mm ±10% T>5mm ±0.50mm |

| Out of roundness (O) | 2% for D/T<100 To be agreed for D/T≥100 | - |

| Squareness of side | - | 90° ±1° |

| External corner profile | - | T≤6.0mm 1.6T to 2.4T 6.0mm< T≤10.0mm 2.0T to 3.0T T>10.0mm 2.4T to 3.6T |

| Concavity/convexity (x) | - | ±0.8% with a minimum of 0.5mm (independent of the tolerance on outside dimensions) |

| Twist (V) | - | 2mm plus 0.5mm/m length |

| Mass (M) | ±6% on individual lengths | ±6% on individual lengths |

| Straightness | 0.20% of total length and 3mm over any 1m length | 0.15% of total length and 3mm over any 1m length |

| Length | +50mm/-0mm | +50mm/-0mm |

EN-Tubes-Product-Structural-Forcon-500/600/700-Supply conditions-TSN

Certification:

3.1 inspection certificate according to EN10204

Our structural hollow sections are also available as Tailored Tubes Forcon®TT with several extras customised to your needs.

EN-Tubes-Product-Structural-Forcon-Available Extras-TSN

Forcon® TT is a customised cold formed welded structural hollow section.

You can choose from several extras such as

- different weld seam options

- tighter dimensional tolerances

- an improved surface finish

- a bespoke chemical composition

- exact lengths

- extra testing

- special packaging

We are happy to explore how we can meet your specific requirements with our Tailored Tube options.

Please get in touch.

- Zeremis® Carbon Lite: Our low carbon emission steel solution offering the potential for up to 90% reduction in CO2 intensity.

For hollow sections according to EN10210 please visit Celsius® hot finished hollow sections | Tata Steel UK

EN-Tubes-Product-Structural-Forcon-500/600/700-Downloads-TSN

Documents for high strength steel

The brochure and datasheets are also available in Dutch, German or French.

Please get in touch if you would like to receive them.

EN-Tubes-Product-Structural-ForconTT-Datasheet-InternalScarfing-TSN

Datasheet Forcon®TT Internal Scarfing

EN-ConstructionEngineering-Download-EPD-Tata Steel Structural hollow sections

EPD Forcon structural hollow sections

EN-Tubes-Contact-TSN

Tata Steel Nederland Tubes

Souvereinstraat 35

4903RH Oosterhout

Netherlands