Steel for safe, strong and durable applications

Steel in industrial applications relies on consistent quality:

- Safety is important in pressure vessels where safe operating pressure is critical

- Strength is crucial in racking and shelving applications where steel can be used to support heavy item storage or allow for higher shelving solutions

- Durability is key to build steel frames for solar panels so they can outlast the panel itself and withstand extreme weather.

Tata Steel’s products for industrial market segments are characterised by an excellent quality-cost ratio helping you succeed in your market. We make steel you can rely on to manufacture your products to the high standards your applications demand. We're ready to help you make your best choices.

Meeting high standards

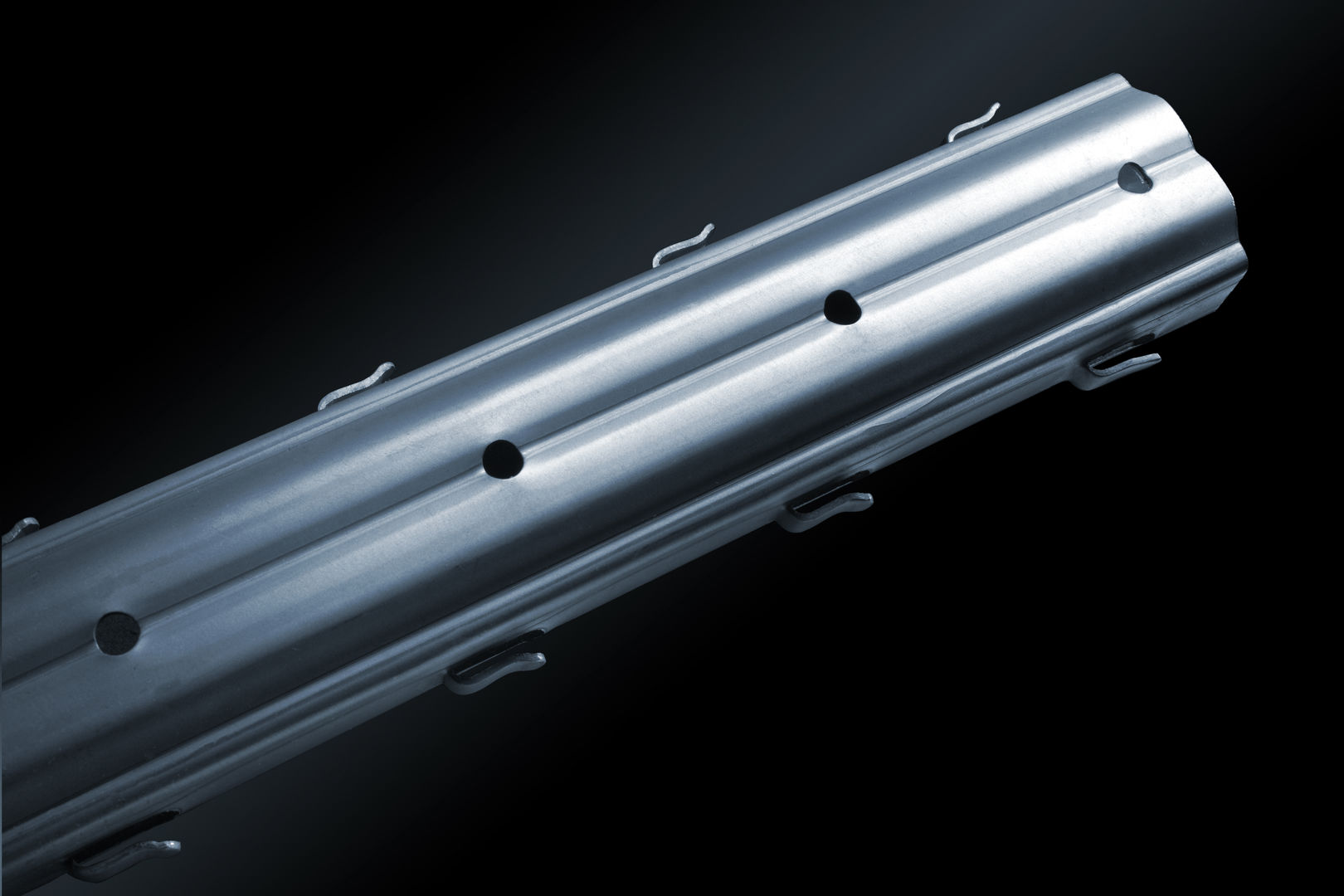

A number of factors have to be considered when designing pressure vessels and gas bottles. Not only does this include the size and weight of the vessel and bottles and its contents, but also the internal and external forces, temperatures that they will be exposed to, both ambient and operational, stresses, corrosion and much more. Our structural steel for pressure vessels and gas bottles delivers excellent impact toughness and weldability. They are designed to withstand immense internal pressure.

Silos may be subjected to lower pressures, but the strength requirements can be very high. Silos are increasingly designed for cost effectiveness while at the same time providing excellent reliability for their purpose of storing more and more challenging products.

Securing sustainable growth

The solar energy industry is expanding fast. Many homeowners and companies considering solar panels are looking for a product that will both generate energy and offer an aesthetic improvement for their property.

We offer steel for solar panel frames. These light gauge frames form an excellent base for installing solar panels either at ground level or on rooftops. The steel frames offer a solid basis and are designed to last as long as the solar panels and are able to withstand all kinds of weather conditions.

Meeting international standards

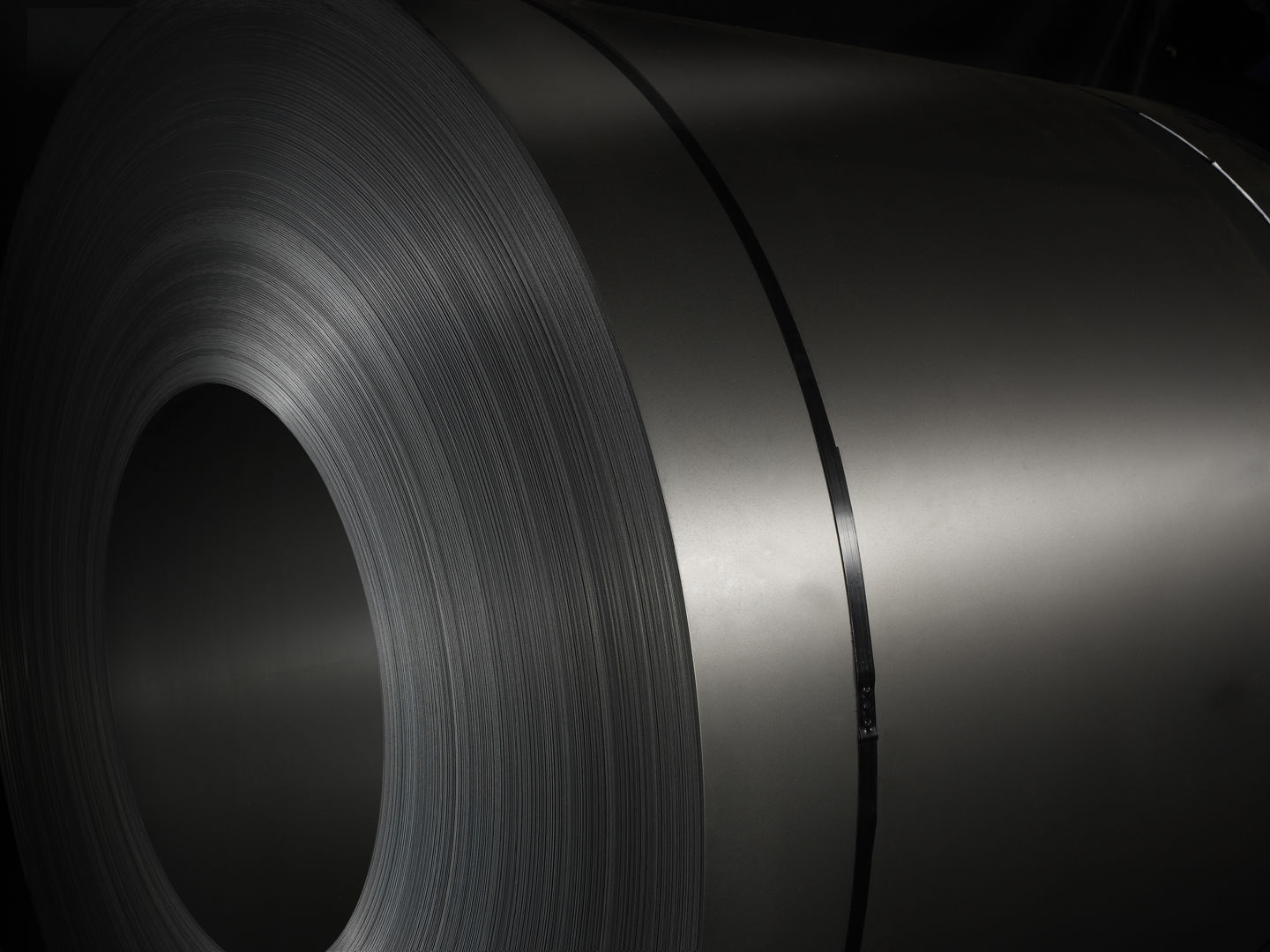

Cold-rolled steel is used to produce steel drums where safety is a key feature when for example storing and shipping hazardous products across the globe. Its strength comes from a tight standardised manufactured material. It is able to withstand outstanding mechanical stresses. Further when it comes to drums, the surface quality of steel has excellent characteristics for painting or lining.

Steel drums are an excellent example in terms of circularity: they are reused multiple times and at end of life, they are recycled, processing them as steel scrap and then transforming them into new steel products.

Offering the right steel

Supporting you globally

Tata Steel is one of the world’s most geographically diversified steel producers with operations in 26 countries and commercial offices in more than 35 countries.

Through serving many demanding markets worldwide, including construction and infrastructure, automotive, packaging and engineering, we understand our customers' needs are different in each market.

Please contact us for further information, or if you have questions and enquiries. Our material experts are there to support you.

Creating synergies by working together

Our Customer Technical Services (CTS) team will work closely with you to understand your business. Using our in-depth knowledge of steel grades and customer manufacturing processes, we take a proactive approach to support - customising product and process solutions to suit your operations and markets.

Downloads

Structural steel - hot-rolled - downloads

Linssen Yachts - case study (EN)

Linssen Yachts - Fallstudie (DE)