Layde Steel slu is located in Durango, Spain, very close to the port of Bilbao. This offers very good logistics for our incoming Tata Steel material from the Netherlands and the UK. Our steel service centre processes and supplies a wide range of flat steel products to a variety of demanding sectors including:

- construction

- home appliances

- furniture

- general industry

With its pickling and cold rolling facilities, our Layde steel service centre in Spain can produce materials with stronger mechanical properties and tighter thickness tolerances, as well as high levels of surface quality not achievable at regular steel mills.

Proven capability

Layde Steel has been serving customers since 1941. We slit and package coils and sheets to meet your exact needs. We offer the following steel products:

- pickled

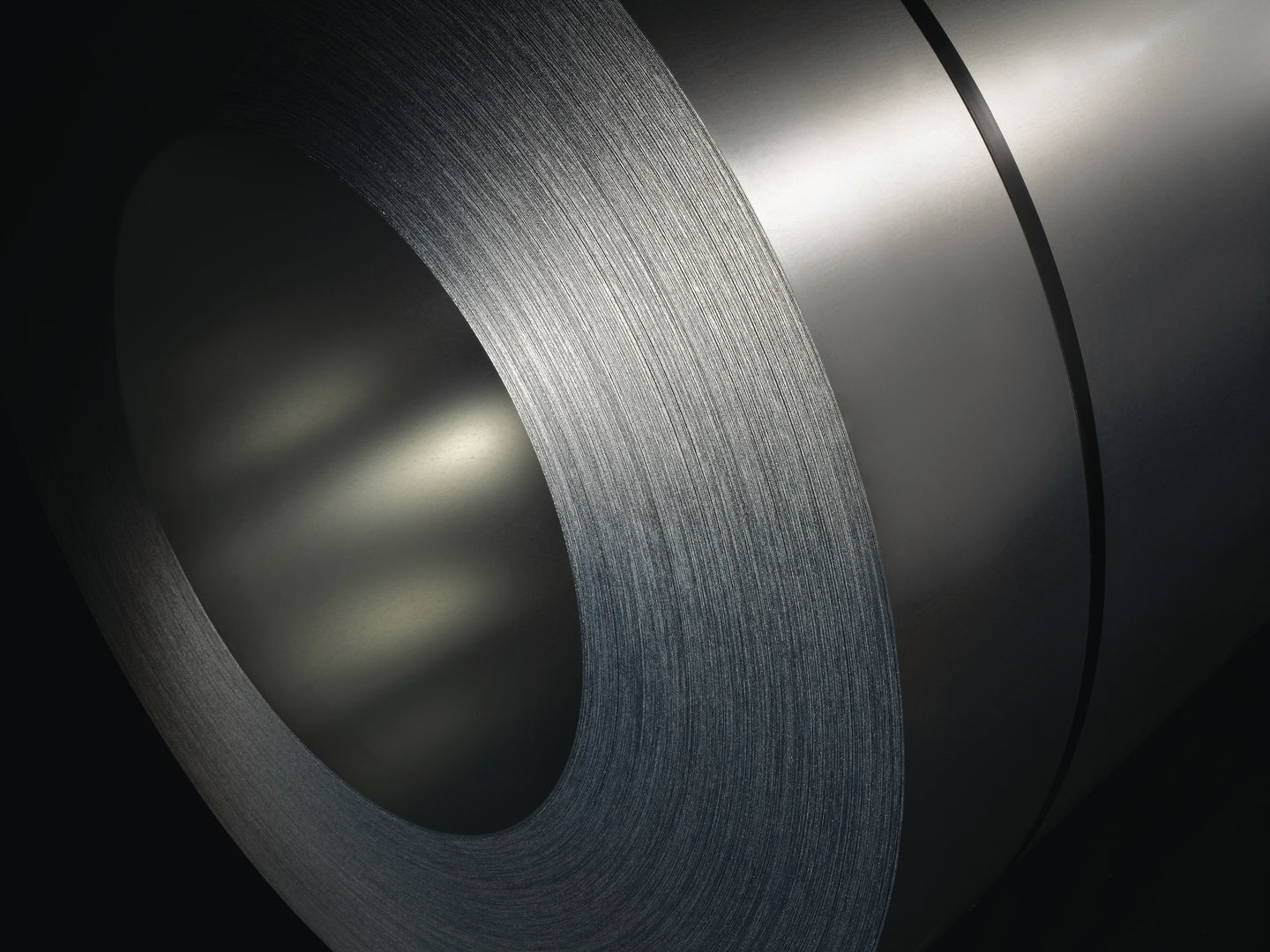

- standard cold-rolled

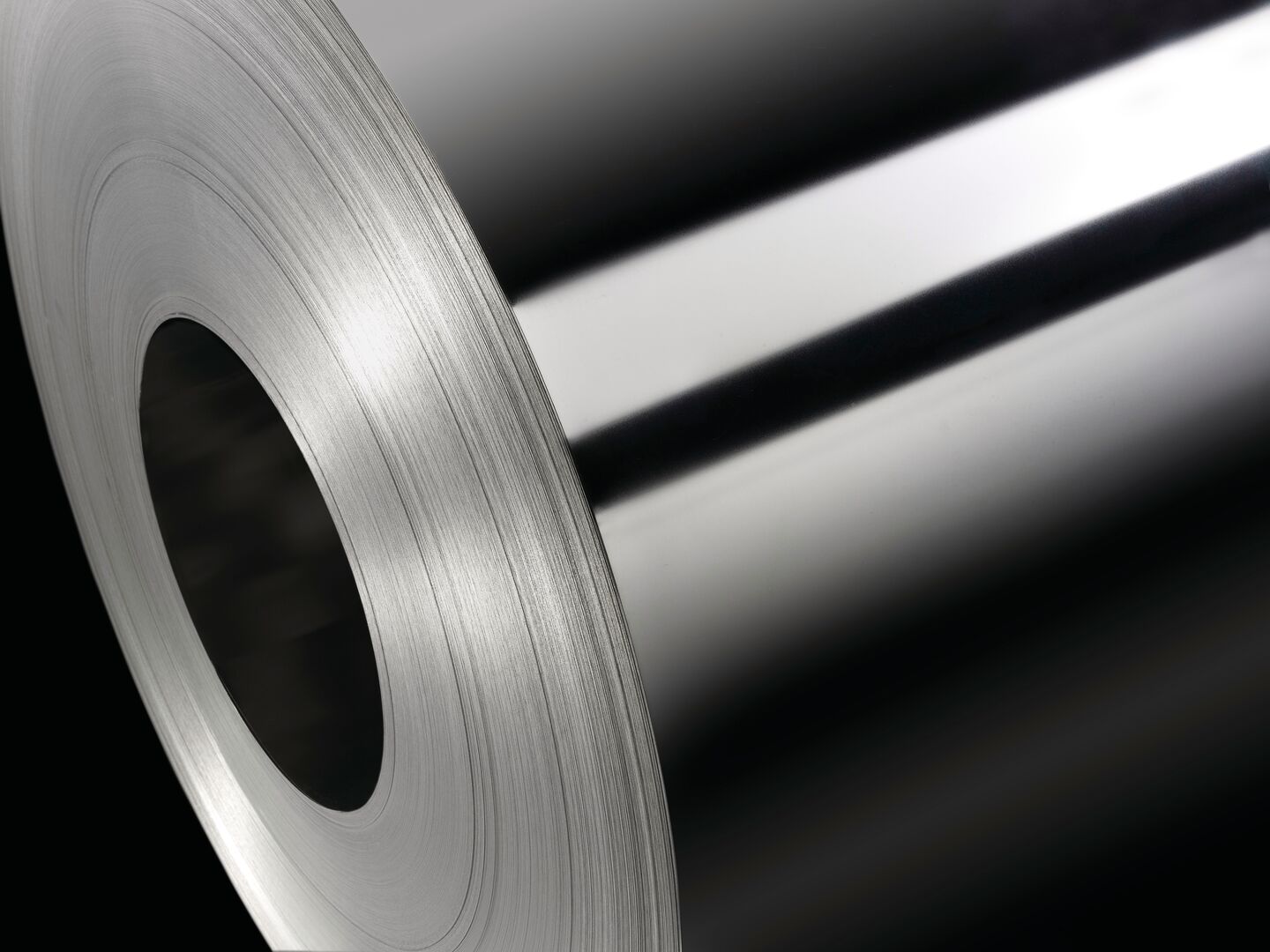

- hot-dip galvanised and electrozinc-plated steel

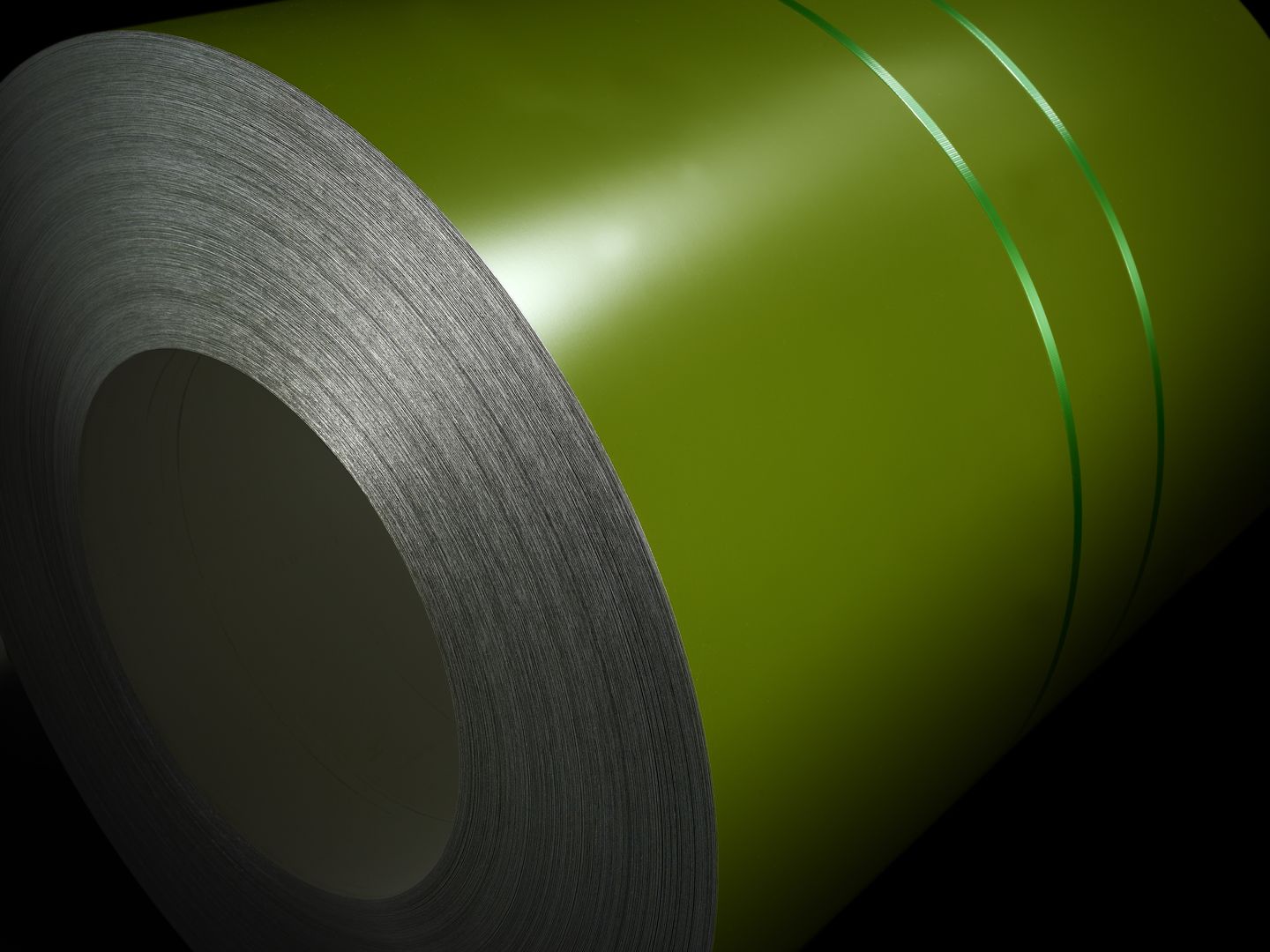

- Pre-finished or organic-coated steel

Wide range of flat products

These following standard grades are available, with all properties following the Euronorm.

- Pickled - DD11 to DD14 - EN 10111

- Pickled - S235JR to S355JR – EN 10025

- Pickled - S315MC to S700MC – EN 10149

- Galvanized - DX51D + Z/ZF to DX57D+Z/ZF - EN 10346

- Galvanized - S220GD+Z to S550GD+Z - EN 10346

- Galvanized - HX260LAD+Z/ZF to HX420LAD+Z/ZF - EN 10346

- Galvanized - HCT600X+Z/ZF to HCT780X+Z - EN 10346

- Organic coated – Upon demand – RAL XXXX

We operate several slitting lines and one cut-to-length line. We can produce strips and sheets in the following dimensions:

- width - from 10mm to 1650mm

- length - from 300mm to 6000mm

Tailored solutions

We improve our processes continuously in order to add value and deliver tailored solutions to our customers. We have a dynamic, flexible and agile team that works hard to achieve cost-effective operations. Our service centre is certified to the ISO 9001:2008 standard.

Environmental performance

Protection of the environment is one of the pillars of our business strategy. We have implemented an Environmental Management System based on international standard ISO 14001:2004. You can find additional information in our downloads section .

Layde has the following facilities, operated by highly-qualified people:

Pickling line

Our pickling line is a 136m long facility that uses a hydrochloric acid bath to remove the surface oxide layer on hot-rolled coils. This ensures the surface is completely clean and dry - allowing post-process oiling and eliminating the risk of oxidation. This facility is directly connected to a slitting line where we produce strips to the final width required by customers.

Cold rolling

Our facilities consist of two reversing 650mm SENDIZIMIR cold rolling mills. Thanks to them we can produce very fine tolerances across the entire thickness range. Our manufacturing range is between 0.20mm and 3mm (gauge) and between 10mm and 650mm (width). Inner diameters are 400-508mm depending on the product.

Annealing

Our EBNER furnaces are fully automatic. They use natural gas and a 100% hydrogen atmosphere that delivers an equal temperature in the whole coil. This ensures identical mechanical characteristics throughout the entire coil. This process also prevents contractions that can cause marks and scratches on the coil surface. Use of hydrogen provides a coil surface that is extraordinary clean and oil-free.

Slitters and Cut-to-Length (CTL)

For processing our precision cold-rolled, galvanised, electrozinc coated and pre-finished steel coils, we have different slitters and a cut-to-length facility. These produce material to meet the final dimensions required by customers. Our capabilities are: from 25mm to 1850mm (width) and from 300mm to 6000mm (length).

Skinpass

We have skinpass facilities that provide material with a slight surface hardening but without modifying any of its mechanical properties. This process delivers a smooth surface within the roughness range demanded by customers.

Dimensional capability

| Slitting | Decoiling | Pickling | |

|---|---|---|---|

| Thickness | 0.2 – 7.0mm | 0.3 – 3.0mm | 1.4 – 7.0mm |

| Width | 10 – 1650mm | 300 – 1500mm | Up to 1300mm |

| Length | - | 300 – 6000mm | - |

Max. pickling strength level is 800 MPa.

Please consult our sales department regarding specific technical feasibility of dimensional combinations, tolerances and grades. You can find details on how to get in touch with us in 'Contact Us' below.

In addition to our service centre activities of slitting and cut-to-length, we also have our own narrow cold-rolling production line. Compared with steel from wide strip mills, our cold-rolling process produces materials with:

- tighter mechanical properties

- tighter thickness tolerances

- better surface quality

Our cold-rolling process begins with pickled hot-rolled coil - pickled at our own pickling line. This coil is cold-rolled to the customer’s required thickness and subjected to annealing prior to a skinpass. This process combination delivers a level of material ductility that makes our products suitable for a variety of applications.

Meeting your requirements - Our cold-rolled material is slit to meet your required width and then packaged for dispatch. We can supply material in the following dimensions:

- thickness - from 0.2mm to 4.0mm, depending on the grade

- width - from 10mm to 650mm

We work closely with our customers - helping you to obtain the best results from our products. Whatever your needs, please don’t hesitate to contact us.

Our cold rolling portfolio includes:

Boron steels - With hardenability equivalent to higher carbon and low alloy steels, boron steels provide consistent wear performance and improved levels of toughness. So they are ideal for applications like shovels, harrow discs, mower blades, agricultural knives and chain side plates.

Freecutting steels - Free-cutting steels are ideal where intensive machining is required, as they increase machining speeds and reduce tool wear. Available either with added sulphur and lead (Gemcut) or without, typical applications include keys, contact boards and other parts requiring rapid metal removal.

These following standard grades are available:

| Grade | Norm |

|---|---|

| C10E to C100S | EN 10132 |

| 51CrV4 and 58CrV4 | EN 10132 |

| 9MnPb28 and 11MnPb30 | EN 10087 |

| DC01 LC-C590 to DC06 | EN 10139 |

| ST 37-2 to ST42-2 | DIN 1623 |

| HC260LA to HC420LA | EN 10268 |

| DC01 EK-DC06 EK, DC03ED-DC06 ED | EN 10209 |

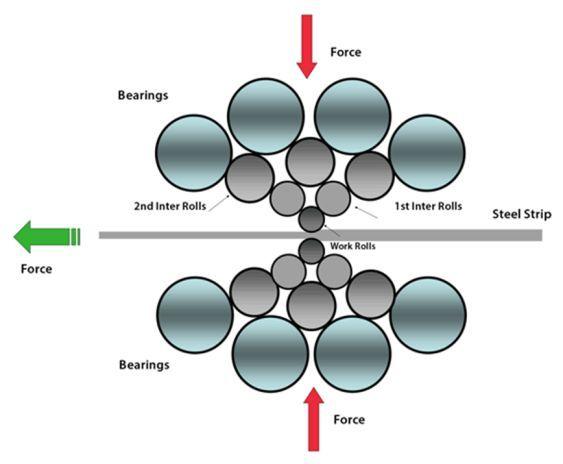

Sendzimir technology

Our cold-rolling process is based on Sendzimir technology. This technology is known worldwide for its ability to roll extremely hard materials to very thin gauges, with few intermediate anneals. It is capable of maintaining very tight gauge tolerances that are difficult to obtain on conventional cold-rolling mills. Sendzimir rolling mills use a cluster of rolls as shown in the picture below.

Work rolls are small in size, allowing significant gauge reduction. Rolls are also easily handled and changed - ensuring the highest surface quality.

Because of their reduced size, work rolls are subjected to high pressures during rolling. Sendzimir rolling mills like ours always have back-up rolls available. The complex design of the rolls enables easy adjustment to achieve maximum material flatness.

Applications

We offer a wide range of narrow cold-rolled products that are used for diverse applications across several market segments. Products made from our materials include coins, keys and filters. The picture below gives examples of what some of our customers are producing from our material.

Certificates and approvals

ISO TS 16949 certificate (English)

ISO 9001 certificate (English)

ISO 14001 certificate (Español)

EN-Service centres-Contact-Spain Layde

Layde Steel slu

Layde Steel slu

Bº Eguzkitza, 11

Ctra. Durango-Elorrio Km 1

48200 Durango - Bizkaia

Spain