Application

- chassis and suspension

- other automotive components

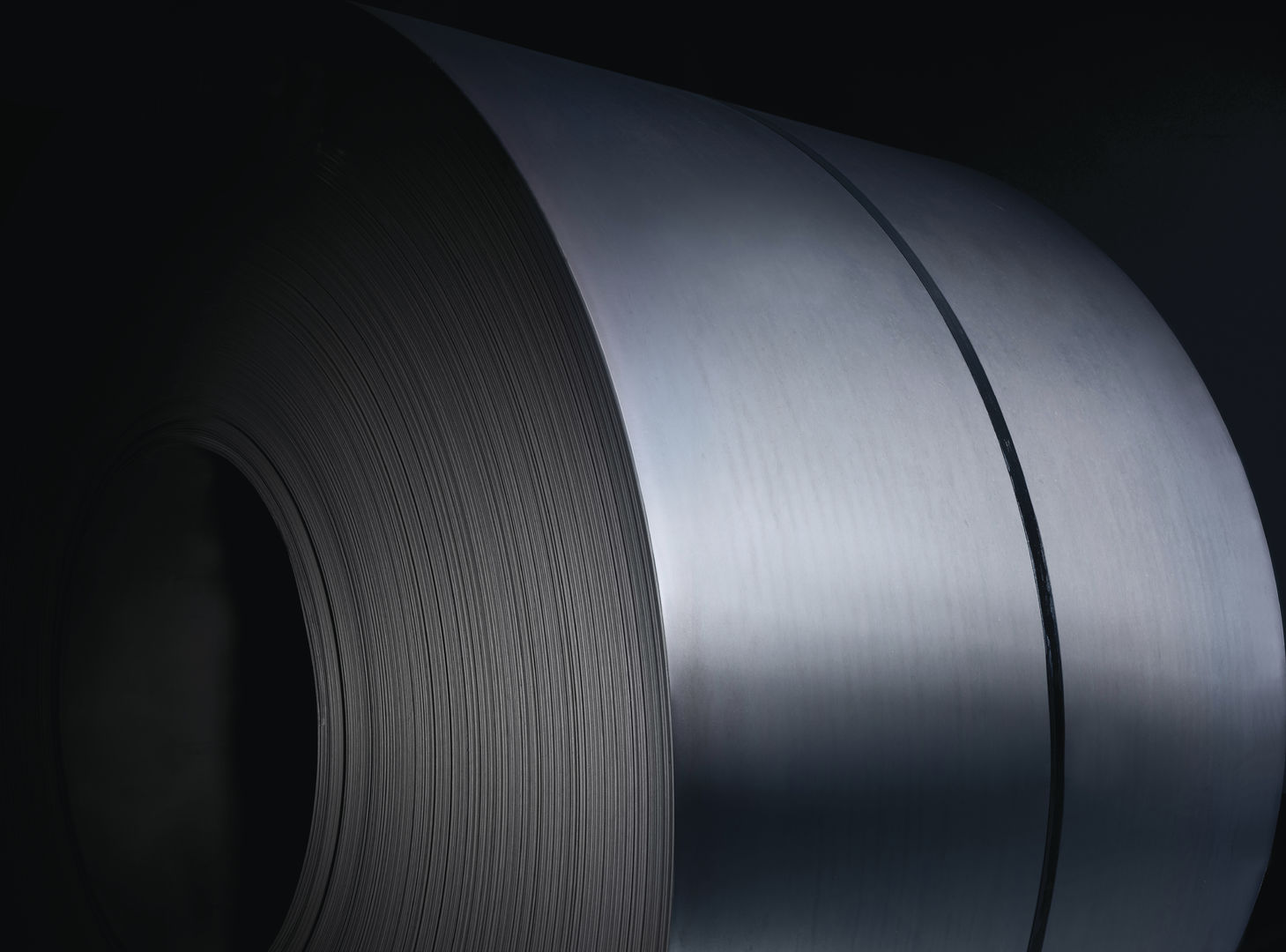

Steel with added benefits

Our products comply with all relevant European standards. We have also enhanced many of our steel grades to deliver added benefits – both for end products and customer processes. Our hot-rolled steel line includes exclusive Tata Steel products developed to increase your yield during component processing and lower your total cost of material application.

The main benefits of our hot-rolled steel include:

- enhanced in-service performance

- extended product life

- stronger, lighter products

- opportunities to reduce your Total Cost of Ownership

- repeatable, reduced-risk processing

- opportunities to simplify processing steps

- material yield improvements

XPF®, our family of single-phase, advanced high strength hot-rolled steels offer or easy lightweighting and increased energy absorbtion.

Hot-rolled product families

EN-Automotive-Product-Hot-Rolled-Forming TSE

Steel for forming

Hot-rolled steel for cold forming is used for bending and deep drawing.

Tata Steel’s forming grades offer consistency for reliable processing and low carbon content for excellent welding performance.

EN-Automotive-Product-Hot-Rolled-HSS TSE

High-strength steel

Tata Steel’s high-strength, low-alloy grades offer formability and strength for demanding applications.

The range includes our Ympress® HSLA – with grades that exceed the Euronorm, resulting in stronger and lighter products with increased yield and simplified processing.

EN-Automotive-Product-Hot-Rolled-AHSS UHSS TSE

AHSS and UHSS steel

Tata Steel’s range of versatile hot-rolled advanced and ultra high-strength steels has been developed primarily to meet the needs of the automotive industry – increasing strength or reducing weight to help achieve optimal performance parameters.

EN-Automotive-Product-Hot-Rolled-Heat treatable steel TSE

Heat treatable steel

Tata Steel offers a choice of hot-rolled heat-treatable steels

Boron steels offer advantages across many applications. We exercise stringent control over chemical composition and production processes, resulting in a robust, consistent and reliable quality you can depend on.

The chemical composition of our boron manganese steel family makes it suitable for forming complex shapes. After a quench and temper step at the customer, the end product will gain its final hardness.

EN-Automotive-Contact-General sales - Automotive - general

Enquiries and customer services

Automotive sales enquiries and customer services

connect.automotive@tatasteeleurope.com

Please contact us for further information, questions and enquiries. Working together on sustainable vehicles and value chains.