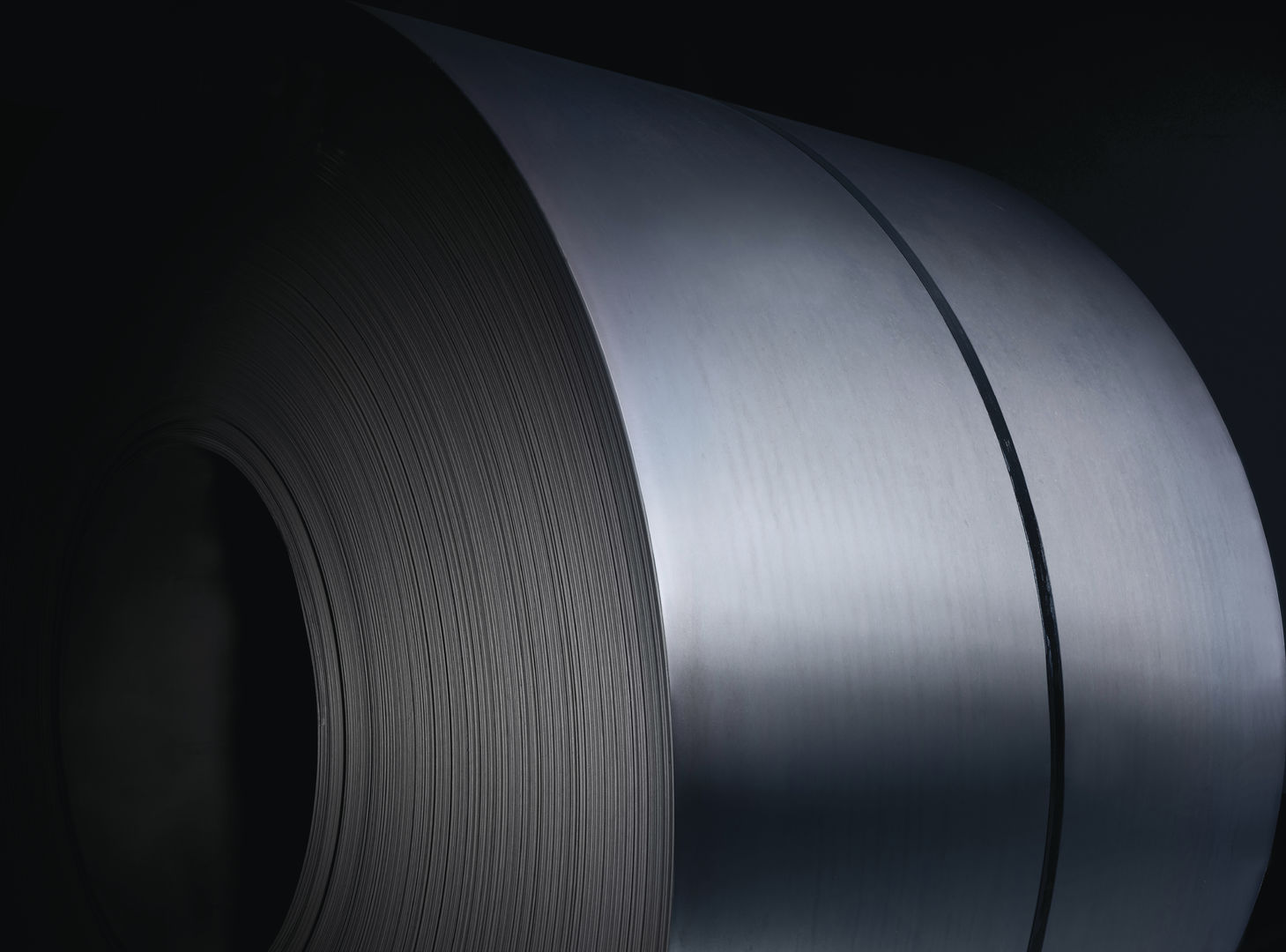

Tata Steel’s line of hot-rolled strip steel includes forming and structural grades, heat-treatable steels and advanced and high-strength low-alloy steels.

All are specially designed for specific and demanding applications. You can rely on the consistent quality of our hot-rolled steel. Our products comply with all the relevant European standards.

We have also enhanced many of our steel grades to deliver added benefits – both for end products and customer processes. Our hot-rolled steel line includes exclusive Tata Steel products developed to save you money and make your life easier. These include Ympress® Laser, developed specifically for fast and efficient laser cutting.

The main benefits of our hot-rolled steel include:

- enhanced end product performance

- extended product life

- stronger, lighter products

- opportunities to cut costs

- repeatable, trouble-free processing

- opportunities to simplify processing

- maximised yield

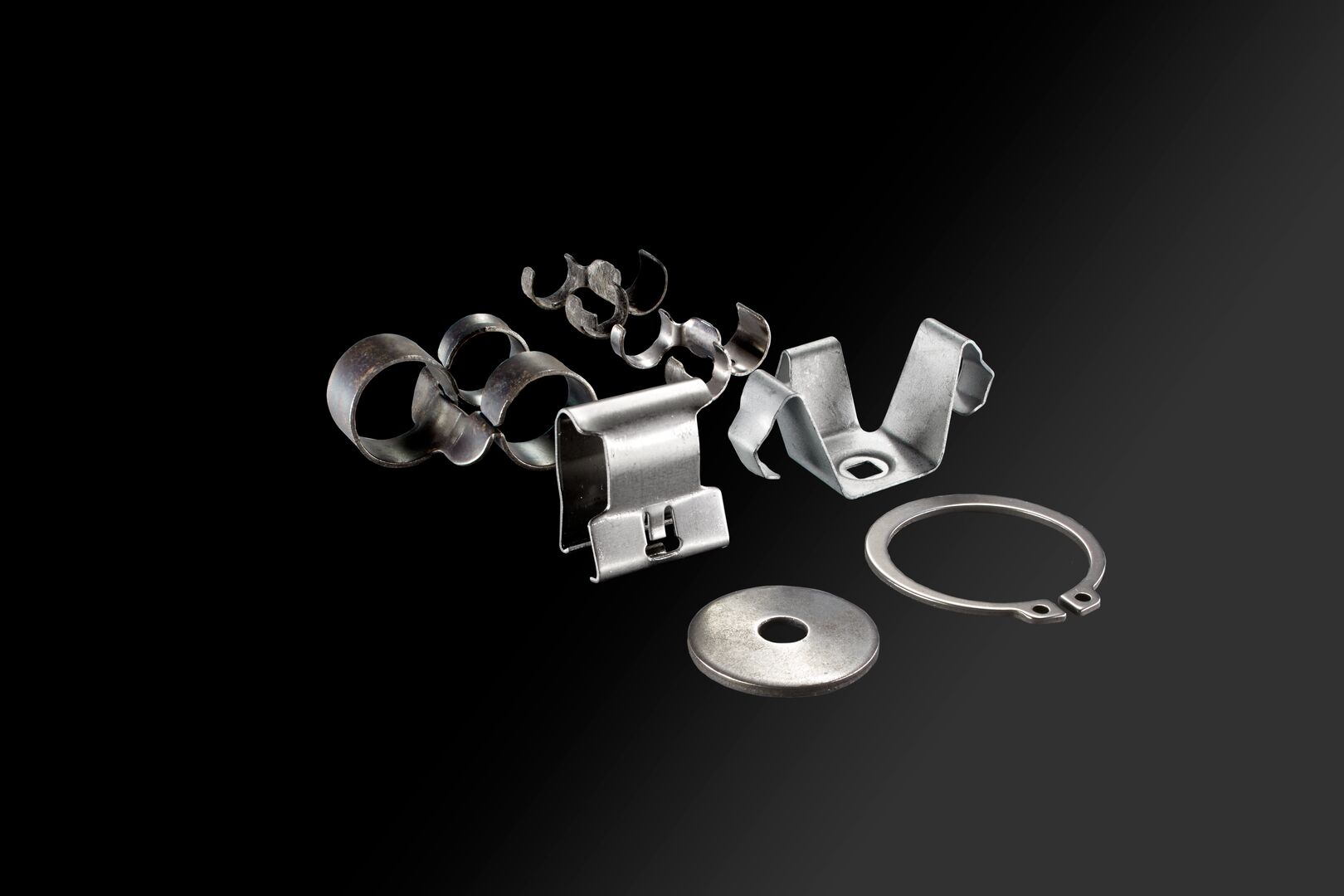

Applications

- Agricultural equipment

- Automotive components

- Construction and building components

- Domestic appliances

- Electrical goods

- Infrastructure and equipment

- Pressure vessels and boilers

- Ship plate

- Trucks and trailers

- Tubes

- Heavy vehicles equipment

Hot-rolled product families

EN-Engineering-Product-Hot-Rolled-Forming TSE

Steel for forming

Hot-rolled steel for cold forming is used for bending and deep drawing.

Tata Steel's forming grades offer consistency for reliable processing and low carbon content for excellent welding performance.

Besides grade DD11 we offer also DD12, DD13 and DD14 specify even lower chemical and mechanical levels making them perfect for deep drawing, extra deep drawing and more complex presswork.

EN-Engineering-Product-Hot-Rolled-HSS TSE

High-strength steel

Tata Steel’s hot-rolled high-strength, low-alloy (HSLA) grades offer formability and strength for demanding applications.

The range includes Ympress® with grades that outperform the Euronorm, resulting in stronger and lighter products with increased yield and simplified processing. Our Ympress Laser range was developed specifically for fast and efficient laser-cutting. The resulting clean-cut edges mean end products require less finishing.

EN-Engineering-Product-Hot-Rolled-Structural steel TSE

Structural steel

The guaranteed strength and good weldability of our hot-rolled structural steel help ensure ease of processing and reliable end product performance. As with all our hot-rolled steel products, our structural steel is manufactured under tight controls – for consistent quality that you can depend on.

EN-Engineering-Product-Hot-Rolled-Heat treatable steel TSE

Heat treatable steel

Tata Steel offers a choice of hot-rolled heat-treatable steels

Heat-treatable steels offer advantages across many applications. We exercise stringent control over chemical composition and production processes, resulting in a robust, consistent and reliable quality you can depend on.

The chemical composition of our boron manganese steel family makes it suitable for forming complex shapes. After a quench and temper step at the customer, the end product will gain its final hardness.

EN-Engineering-Product-Hot-Rolled-Valast abrasion resistant TSN

Valast® abrasion resistant steel

Efficient and reliable abrasion resistant steel sheet withstands harsh wear and tear whilst maintaining lasting quality – even in the most demanding environments.

Tata Steel's Valast wear plate is available in extra-wide strip dimensions, offers consistent flatness and world‑class surface quality. Valast 400/450 is brought to you through a robust local supply chain offering reduced lead times and customised sheet lengths.

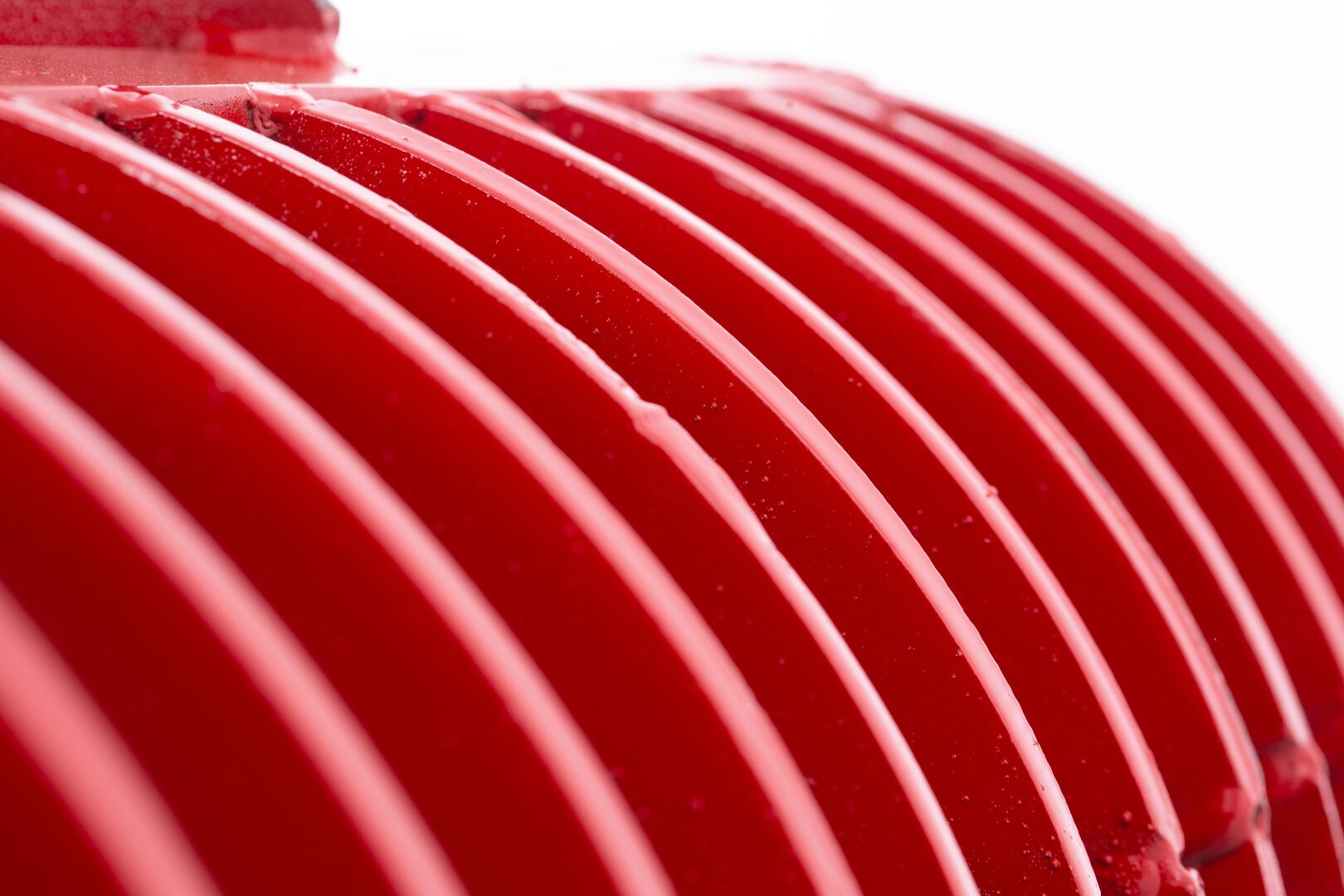

EN-Engineering-Product-Hot-Rolled-Gas cylinders TSE

Steel for gas cylinders

Tata Steel’s structural steel for gas cylinders offers excellent deep drawing properties and weldability for ease of processing.

It allows for reliable normalising of the welded gas cylinder - retaining strength that contributes to optimal safety in use.

EN-Engineering-Product-Hot-Rolled-Pressure vessels TSN

Steel for pressure vessels

Our structural steel for pressure vessels delivers excellent impact toughness and weldability.

Special grades offer guaranteed strength levels at temperatures up to 400°C and steels compliant with EN 10207 and/or EN 10028 for the manufacture of simple pressure vessels.

EN-Engineering-Product-Hot-Rolled-Ship plate TSN

Steel for ship plate

This hot-rolled structural steel offers excellent weldability for ease of processing.

We exercise stringent control over the chemical composition and mechanical properties of our ship plate – ensuring products of consistent and reliable quality for demanding marine applications.

This is proven by an approval of manufacturer from DNV and Lloyds EMEA.

Hot-rolled key products

EN-Engineering-Key Products-Ympress Laser TSN

EN-Engineering-Product-Hot-Rolled-Valast abrasion resistant TSN

Valast® abrasion resistant steel

EN-Engineering-Brochure-Ympress

Ympress - Brochure

EN-Engineering-Brochure-Ympress Laser

Ympress Laser - Brochure