In line with Tata Steel Europe's values, we strive to take emissions into account carefully at every stage of the supply chain. Sustainability and responsible business practices are linked, so we need to look at each area and try to identify potential areas where emissions can be reduced. Naantali Steel Service Centre (SSC), like Tata Steel as a whole, aims to be a CO2 neutral operator.

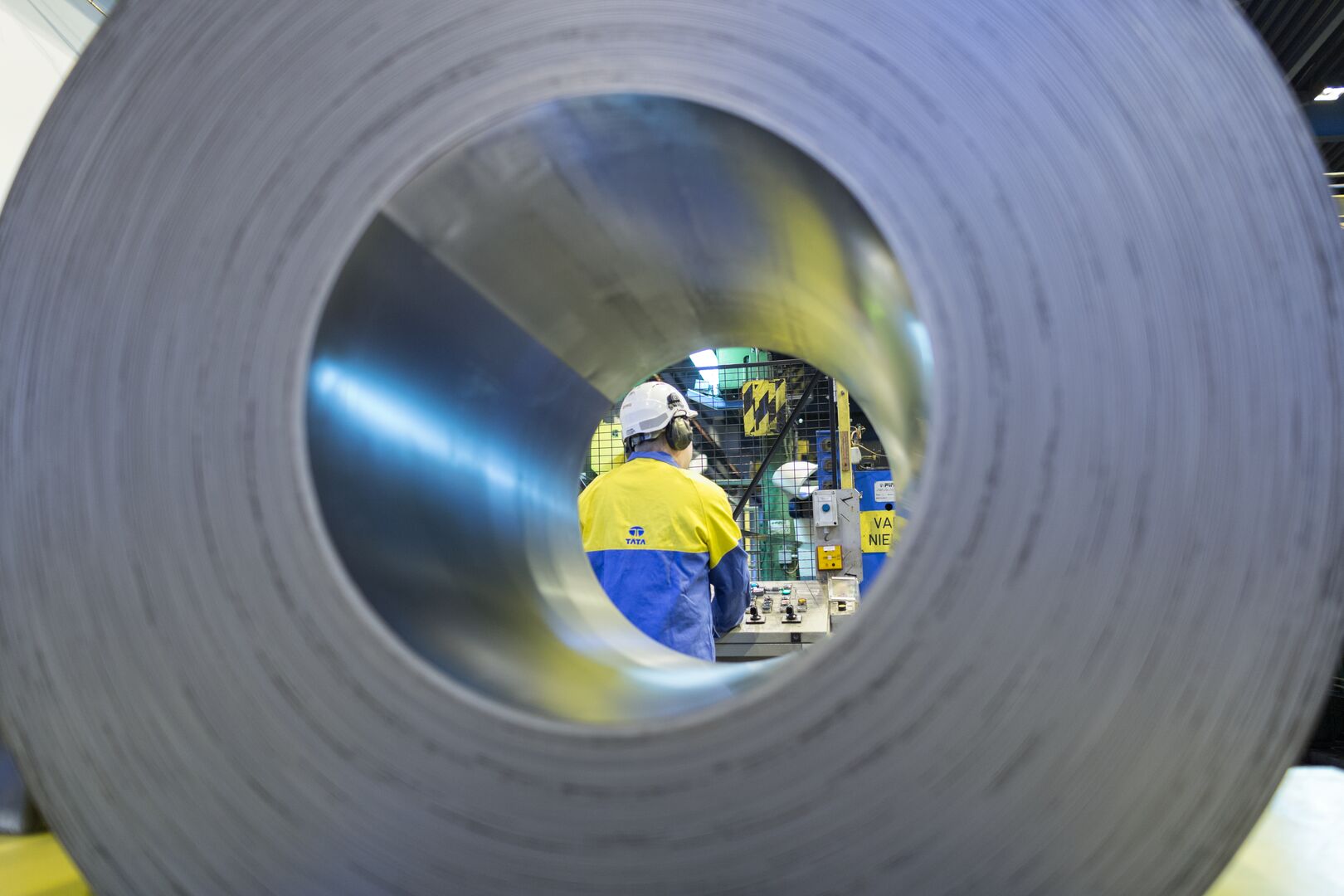

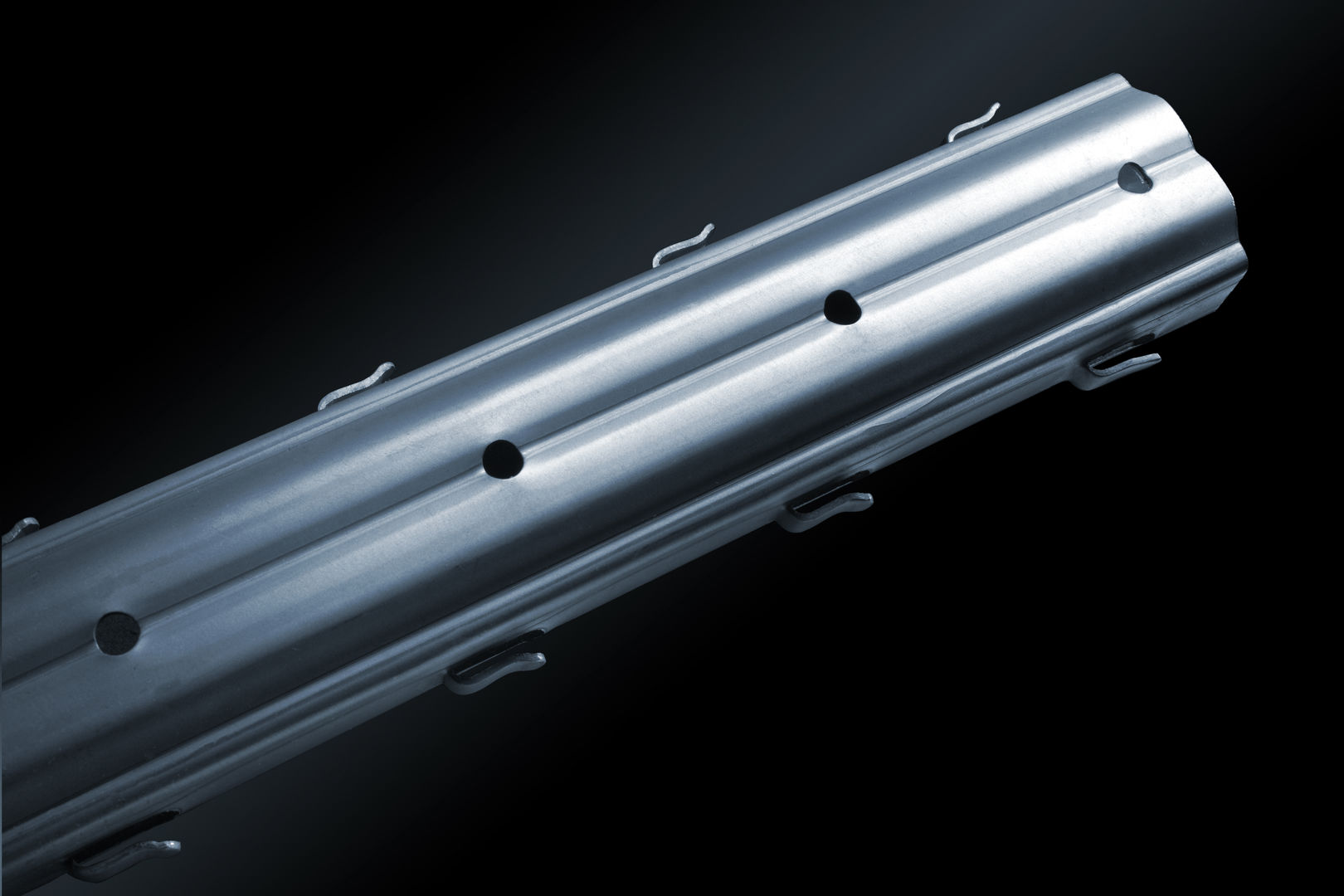

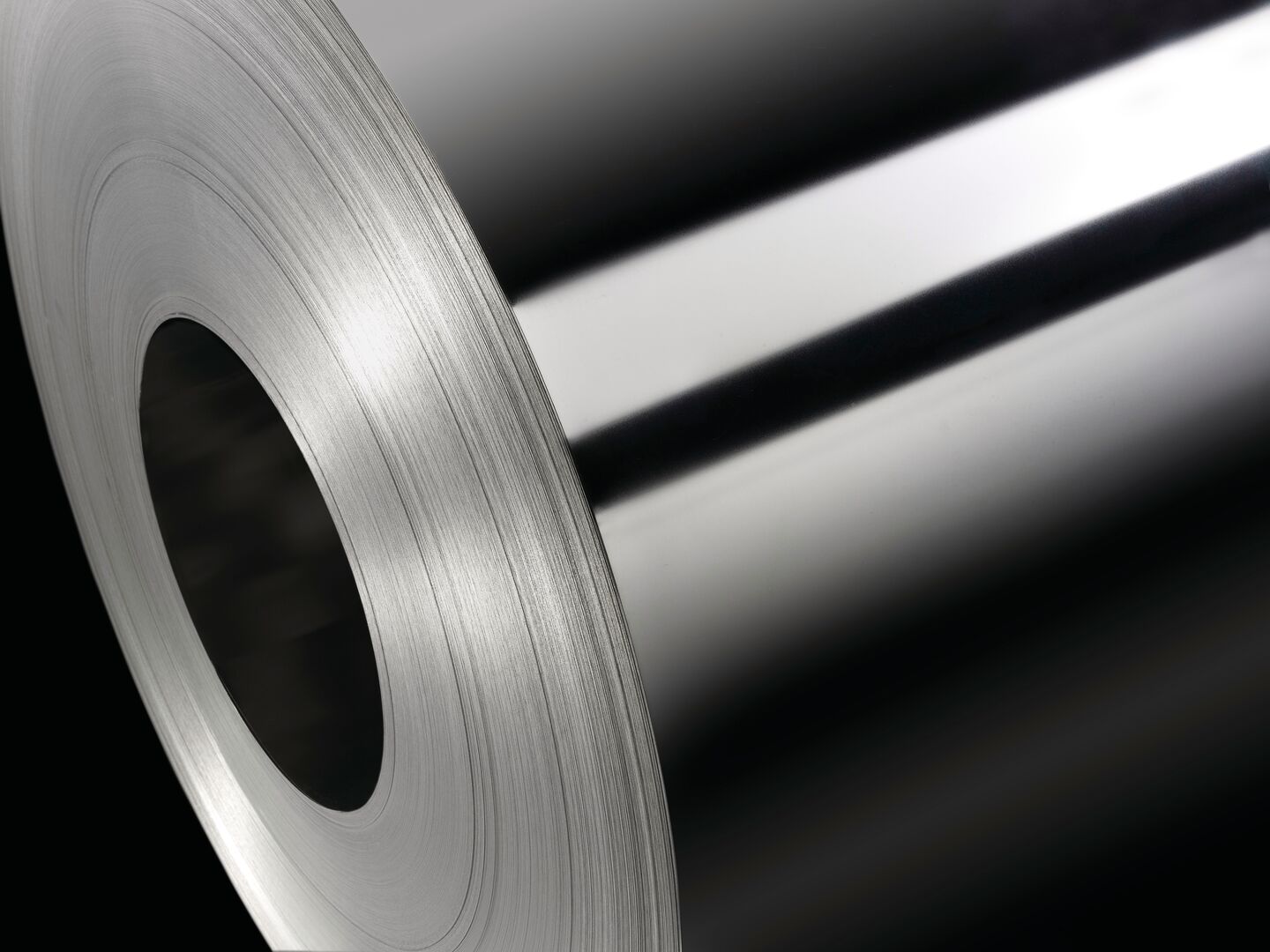

Tata Steel's Naantali SSC is one of the largest production units specialising in sheet metal processing in Finland. Heating a large production facility like Naantali SSC in winter consumes a huge amount of energy. Naantali has a total of 22,000 m2 of heated production space. Of course, heating such a large area also generates carbon dioxide emissions, but the amount of emissions can also be influenced by the choice of heating system.

In late 2021, a mapping project was launched in Naantali to explore alternatives to replace the old natural gas heating system. The aim was to reduce both the environmental impact of Naantali's production and heating costs. After the mapping exercise, a heating system based on air-source heat pumps was selected as the best option in terms of energy efficiency and cost. The system is built by scattering several heat pumps in different parts of the production space, thus ensuring efficient heat distribution. The installation of the system started very quickly after the decision was taken and the new system was commissioned in April 2022.

With the new system, we will reduce CO2 emissions from Naantali's operations by almost 60 tonnes per year. At the same time, the fire safety of the production plant has been significantly improved as we are able to completely eliminate propane. This is a significant step for Naantali SSC towards becoming a CO2 neutral steel service centre.

EN-Service centres-Contact-Finland Naantali

Finland - Naantali Steel Service Centre Oy

Naantali Steel Service Centre Oy

Rautakatu 5

21110 Naantali

Finland