Under the spotlight:

Matthew Teague, Market Engagement Manager

There’s a new employee featured in the ‘Tata Steel spotlight’ – me!

Maybe you’d like to know why I think automation and offsite is the future of construction. Or in what ways steel will contribute to the decarbonisation agenda.

Or perhaps you’d just like to read about how I once ended up captaining a tall ship by accident.

You can also access my articles about steel production, construction platforms, and the future of building design and construction.

My title of Market Engagement Manager is a new role within Building Systems UK. It’s a wide-ranging, external-facing role where I get to engage with our customers daily and support them in their work.

In the construction industry, a lot of products are just put out into the marketplace. Everything basically stops at the factory gate. We aim to be better than that, by getting feedback from the people who use our products in buildings.

I started in a private architectural practice working in conservation architecture. When I saw an advert for a role at London Transport, I had to apply, as my dissertation was about Tube station design.

As a design manager my work involved buses and riverboats as well as the tube, and I was part of the team that delivered the Jubilee Line extension.

My first role when I joined Tata Steel was as an architect, working on design and market intelligence. Over time, my roles shifted from external facing to more internal facing. With my new role, I feel I’ve come full circle and that’s really positive, because I’ve always believed that kind of external engagement has value and Building Systems UK has never had that before.

In 2009 we worked with British Triathlon to create a pavilion for an event at Hyde Park. It was a difficult challenge but one we managed to pull off: a 25m arch with seating and a VIP area that was the first use of post-tensioned steel in the UK.

As fraught as it was at the time, the achievement really stands out. It was used for similar events and the London 2012 games test event in the years after.

The decarbonisation agenda poses a huge challenge, but also a real opportunity. It’s a case of ‘modernise or die’ – it’s simply something we’ve got to do.

The steel industry is moving in the direction of stricter targets, especially in terms of embodied carbon, and that opens up new environments in a carbon competitive marketplace. Steel will become the material of choice once again.

In terms of construction, P-DfMA (a platform approach to design for manufacture and assembly) is the future. It fits with the efficient use of materials, and alternative solutions won’t stack up when it comes to carbon budgets. Modern methods of construction, MMC, is where we’re heading and will remain.

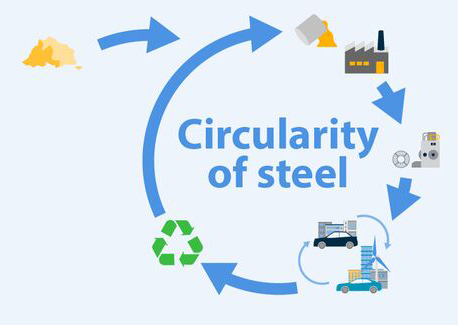

Once steel is created, it never goes away. It has a one-time cost to manufacture and can then be continually recycled – possibly infinitely.

Metals have always been valuable, historically, and they still are. In life cycle assessment, module C looks at end of life scenarios, but we can include module D which looks beyond that. Basically, steel is the circular economy in action.

Construction is moving towards automation and offsite, and I think there’s going to be a lot of focus on productivity, commonality, and reuse.

That will be based around construction platforms, standardised kits of parts, and standard approaches to commonly-built structures. For buildings like warehouses, it will be more usual for nearly all the components to essentially be bought off the shelf. That will open up the market for those same buildings to be disassembled and for the components to be reused.

I design and build bicycle frames, and then sell them – the only problem when I do one is that I lose my weekends for three months! I’ve been doing a lot of outdoor swimming recently too.

I’d have liked to have been a professional cyclist. If I’d have discovered the sport sooner, perhaps that could have happened.

There was the time I ended up as the captain of a tall ship for the day, completely by accident.

We’d paid to crew a boat crossing from Weymouth to Cherbourg, and the professionals all fell ill during the journey. The only qualified navigator was my mate Gary and, by maritime law, that left me as captain! Thankfully the real captain recovered enough to take over again, after a very worrying day.