Trisofix™ universal mounting system

Trisofix™ a simple to use patented universal mounting system. Combined with pre-finished panels and products it creates a true DfMA solution that unlocks both off-site and on-site productivity.

Trisofix™ enables lower carbon, cost and time certain project delivery.

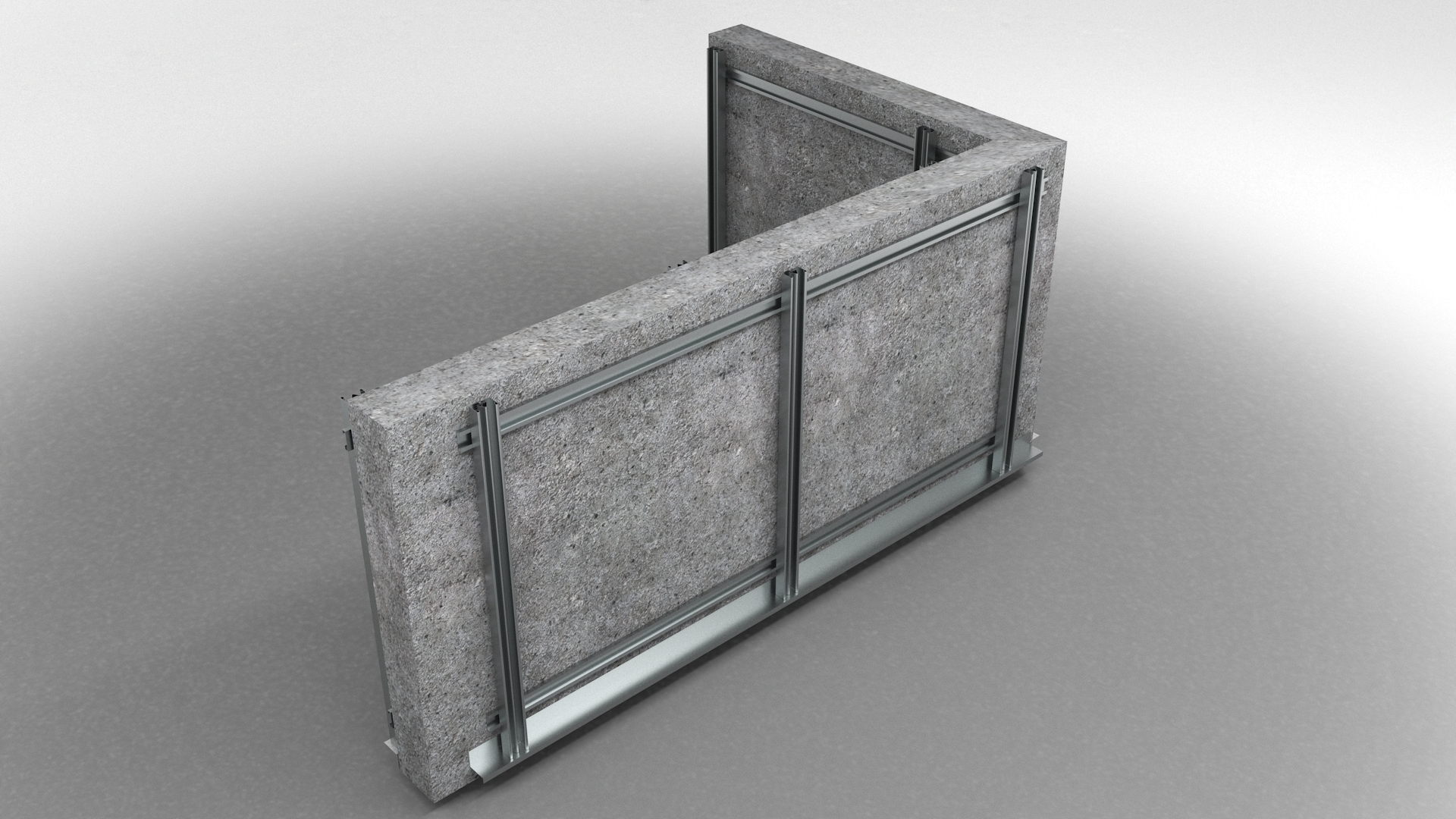

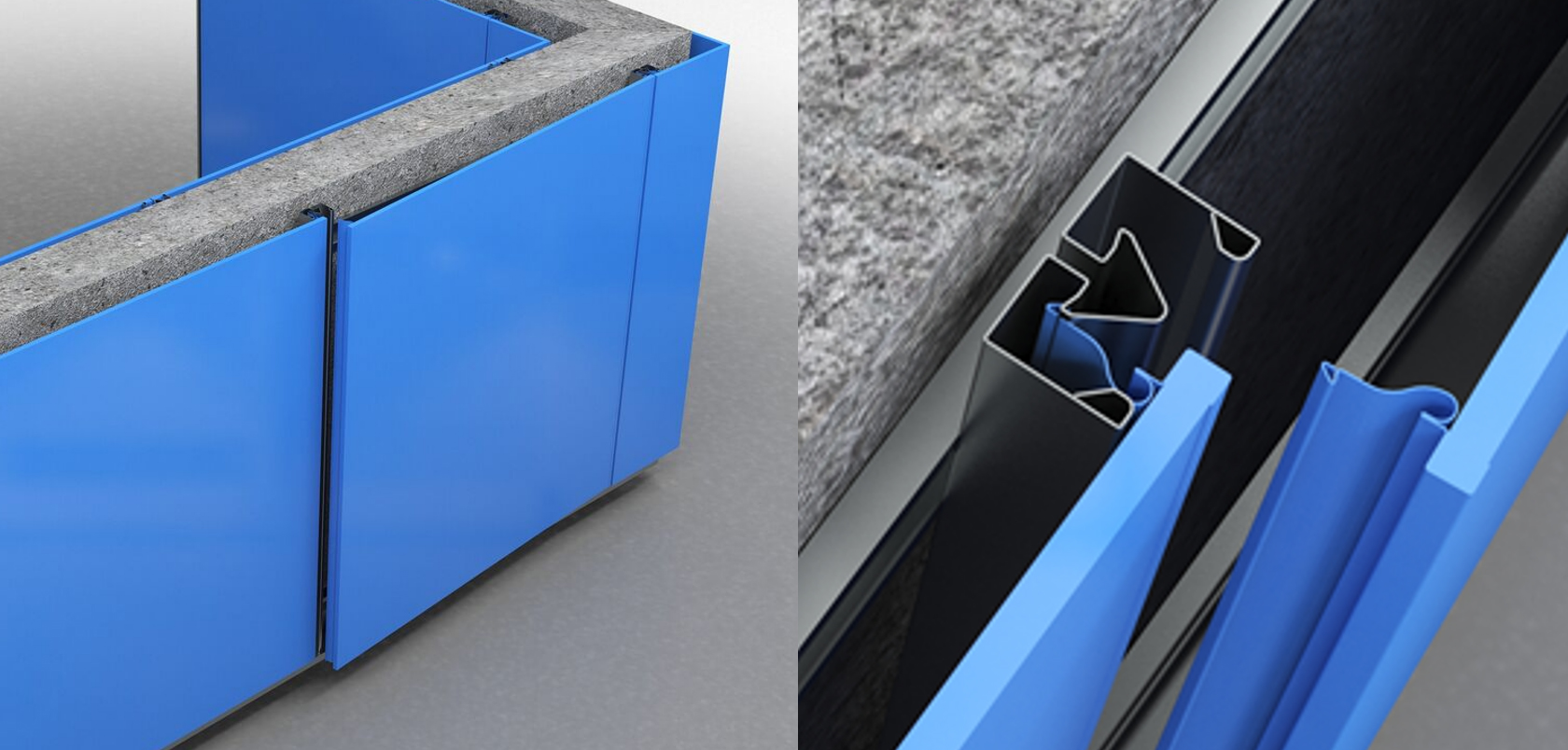

Made using high grade coated steel components the Trisofix™ mounting system fixes back to any structural wall type and can be used throughout a building, both for façades and internal fit out.

EN-Construction-Product-Trisofix-universal-mounting-system

EN-Construction-Product-Trisofix-Benefits

Made using high grade coated steel components the Trisofix™ mounting system fixes back to any structural wall type and can be used throughout a building, both for façades and internal fit out.

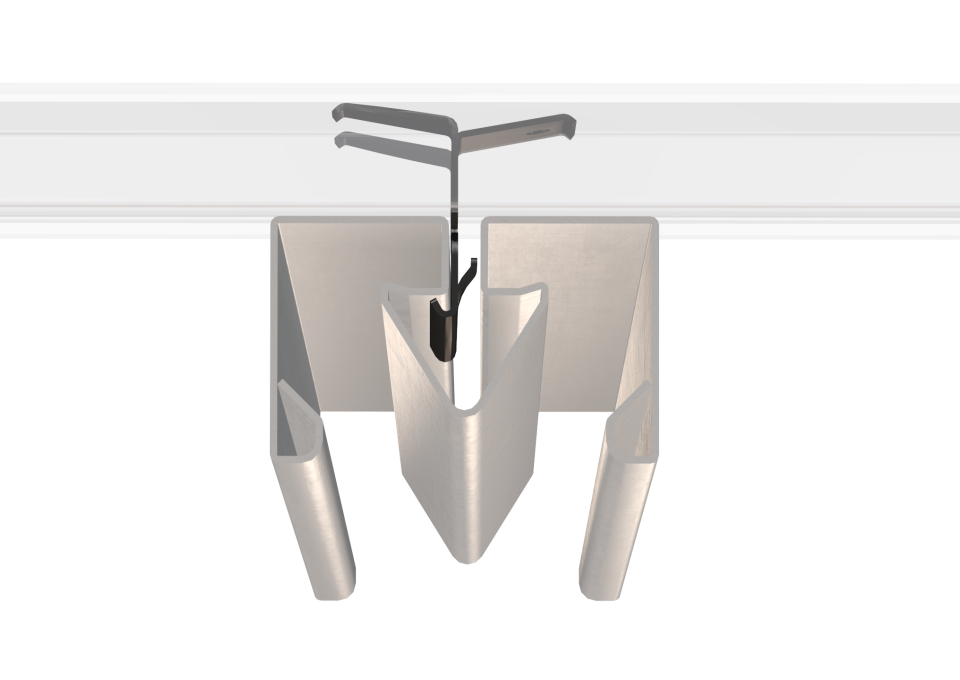

Typically Trisofix’s Fast Fit clip is factory fitted to prefinished panels but can also be fitted on site offering hybrid functionality and flexibility for installers.

Trisofix creates a 55mm cavity behind prefinished panels, which when combined with the individual panel demounting, provides easy access to any services behind, simplifying and speeding up M&E installation.

The robust clip can be continually reinstalled without compromising strength or integrity, and allows panels and products to be removed, replaced, relocated and reused.

While Trisofix™ is fast to fit, the mounting system combines its usability with exceptional strength and durability credentials.

EN-Construction-Product-Trisofix-Sustainability

Steel... a high performance sustainable solution

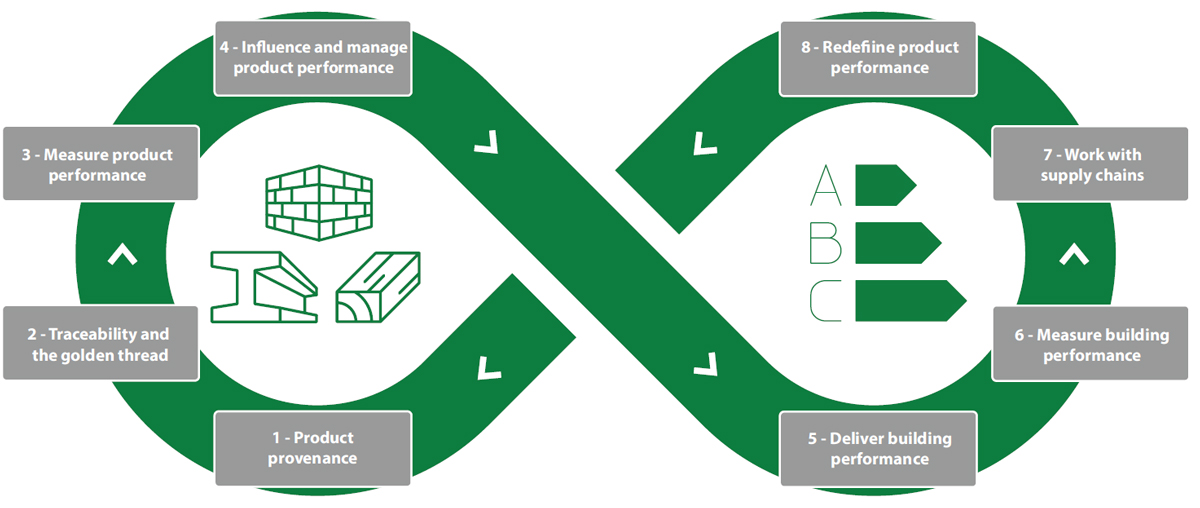

Trisofix™ is manufactured and delivered as a kit of parts in order to minimise the environmental impact during construction and fit out.

One robust system reduces breakages / water damage during installation and minimises the use of sealants, glues, paints, further reducing waste disposal. Being perfectly suited for a circular economy, steel enables the reusage and recycling of many products and is a permanent material that is 100% recyclable with no loss of quality.

Most steel has already been recycled, and the rest will be recycled – always with no loss of its qualities. Strength, fire resistance, circular economy.

Steel... an infinitely recyclable building material

With an extended first use design life and zero degradation in materials properties when recycled, steel is unlike nearly all of the other construction materials, offering sustainability benefits throughout in-use and end of life phases of a building’s life. Tata Steel UK’s manufacturing processes are carefully controlled to the highest environmental quality standards and are ISO 14001 certified with the widest portfolio of construction products certified in the world.

EN-Construction-Product-Trisofix-Kit of parts

Quick and easy installation

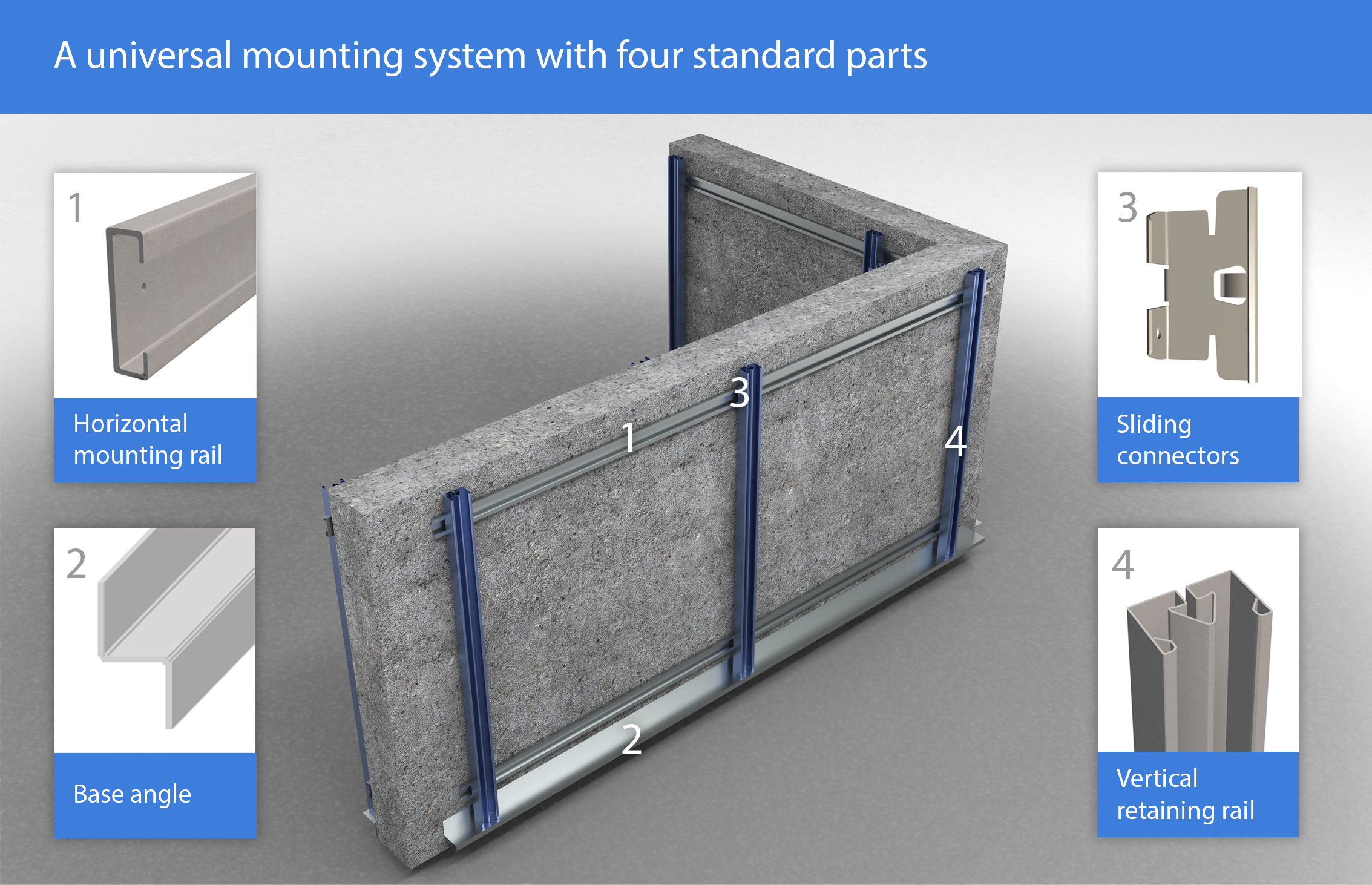

Four standard components provide a universal mounting solution:

| Part | Description | Material | Dimensions | Standard Lengths | Weight (kg/ln) | |

| 1 | Horizontal Mounting Rail | Lipped C section provides main mechanical fix into structural wall | 1.6mm Galvanised steel | 55mm x 20mm | 3000mm | 1.5 |

| 2 | Base Angle | Z profile create a level base for panels and support for skirting | 2.0mm Galvanised Steel | 65mm x 60mm x 65mm | 3000mm | 3 |

| 3 | Sliding Connector | Twist in fit steel connetor allows easy positioniong of vertical rails | 1.0mm eCoated spring steel | 62mm x 32mm | n/a | n/a |

| 4 | Vertical Retaining Rail | Push fitted onto sliding connectors it then provides the receptor for Trimawall panels | 1.0 mm Galvanised steel | 53mm x 34mm | 2800mm | 1.7 |

EN-Construction-Product-Trisofix-Tool-Free

Fast & efficient wall finishing

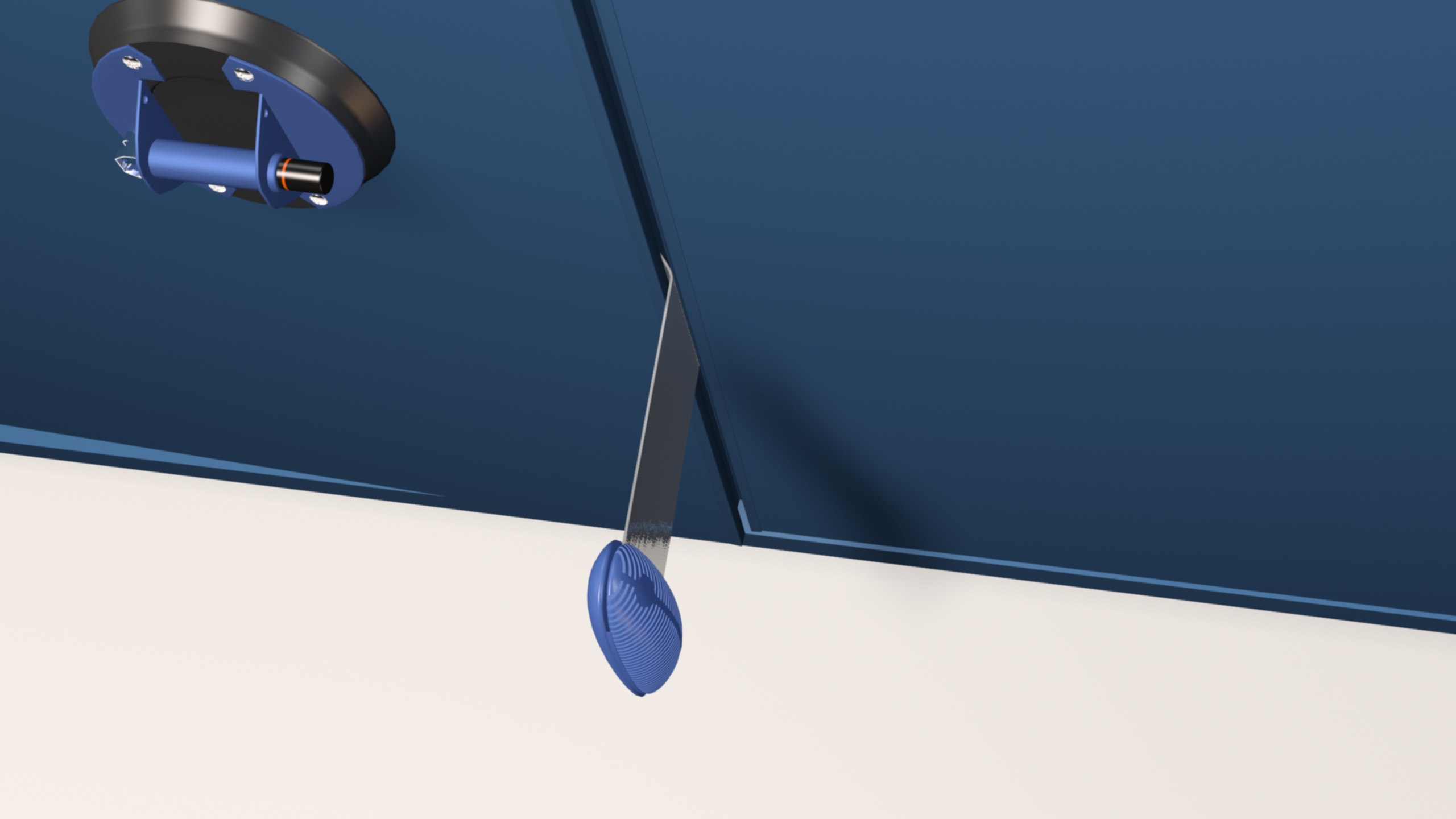

On-site, panels can typically be lifted with vacuum lifters and push fitted by a 2 person installation crew. With the pre-finished panel requiring no additional wet trade finishing Trisofix™ helps simplify and condense the total fit out and finishing process.

Individually demountable panels

Panels can be individually demounted by a 2 person crew using vacuum lifters and the Building Systems UK Trimawall demounting tool. The panels can be demounted and reinstalled multiple times without compromising performance or aesthetics. Not only does this allow for easy access to the M&E services within the cavity for maintenance or upgrading, but it allows panels to be relocated, reused, replaced to help reconfigure and enhance buildings over time.

EN-Construction-Book a CPD

We offer a range of face to face and online CPDs aimed at Engineers and Architects

These free seminars can be booked at any time between 9am and 5pm. Our online webinars can all be delivered via Skype for Business and Teams, but we can consider other platforms if this will not work for your practice.

Below outline the CPDs we have available - Book yours today

- Decarbonising your structural hollow section designs

- Essentials of Structural Hollow Sections

- Welded Joints in Tubular Steelwork - Eurocode 3 Part 1-8

- Concrete Filled Hollow Sections - Composite Design – Eurocode 4

- Composite Floor Deck in Construction

- Structural Roof Deck in Construction

- Specifying metal clad envelope systems in accordance with ADB2 of the building regulations and the value of large scale system testing

- RIBA 2030 climate challenge: How steel building envelope solutions contribute

- Pre-finished steel standing seam systems for roof & wall cladding

- CDM regulations 2015 and their impact on steel building envelope specification.

- Steel building envelope systems for non-domestic buildings

- Steel for roof and wall cladding

EN-Construction-Product-Trisofix-downloads

Find related downloads below for your project specification: