Whilst tubes may look the same, they are not. Tubes made by different manufacturing routes can result in significant differences in reliability, performance and compliance.

Tata Steel’s UK made welded - hot-finished – tubes, deliver a range of advantages over welded cold-formed and seamless imports.

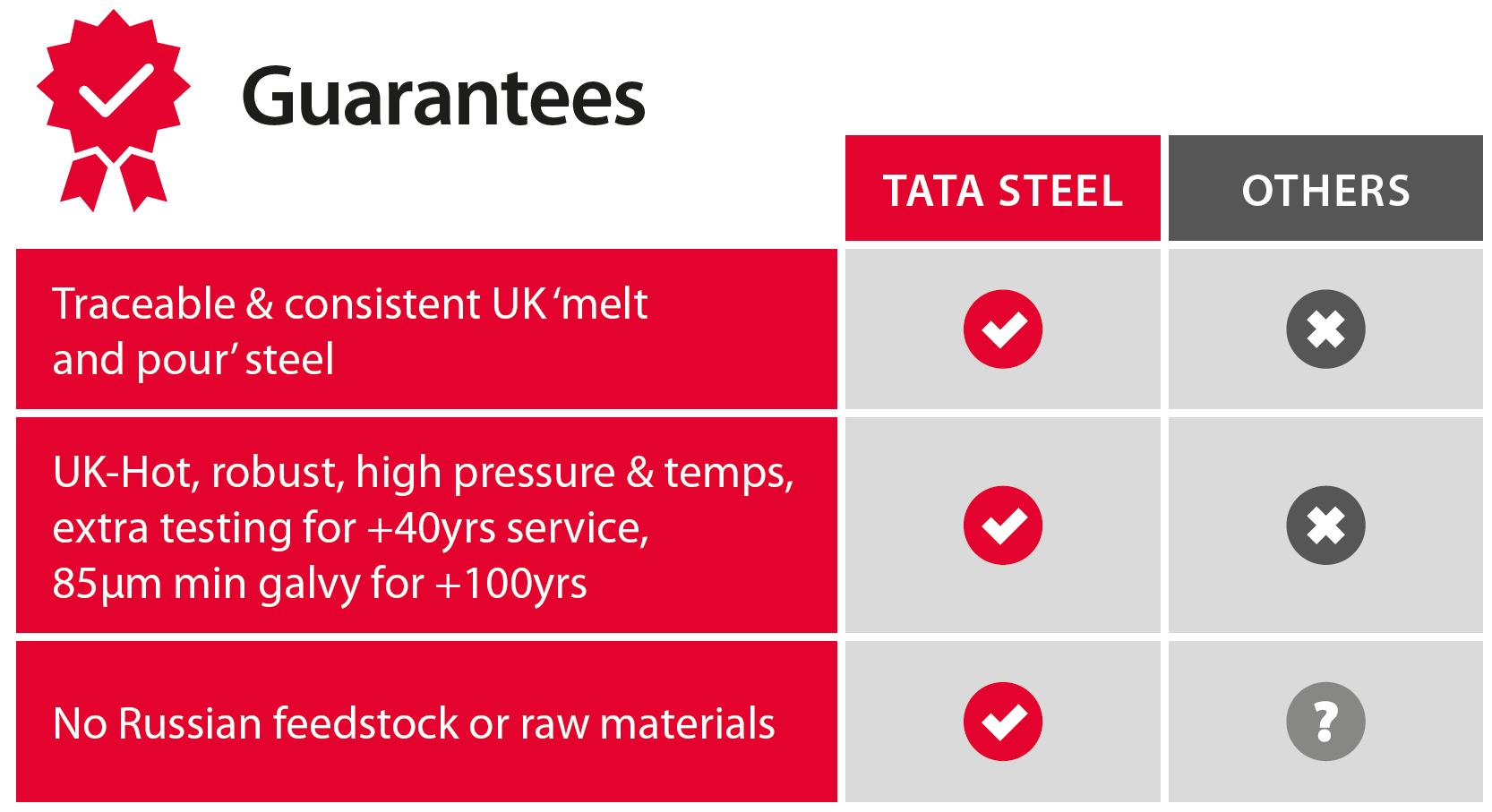

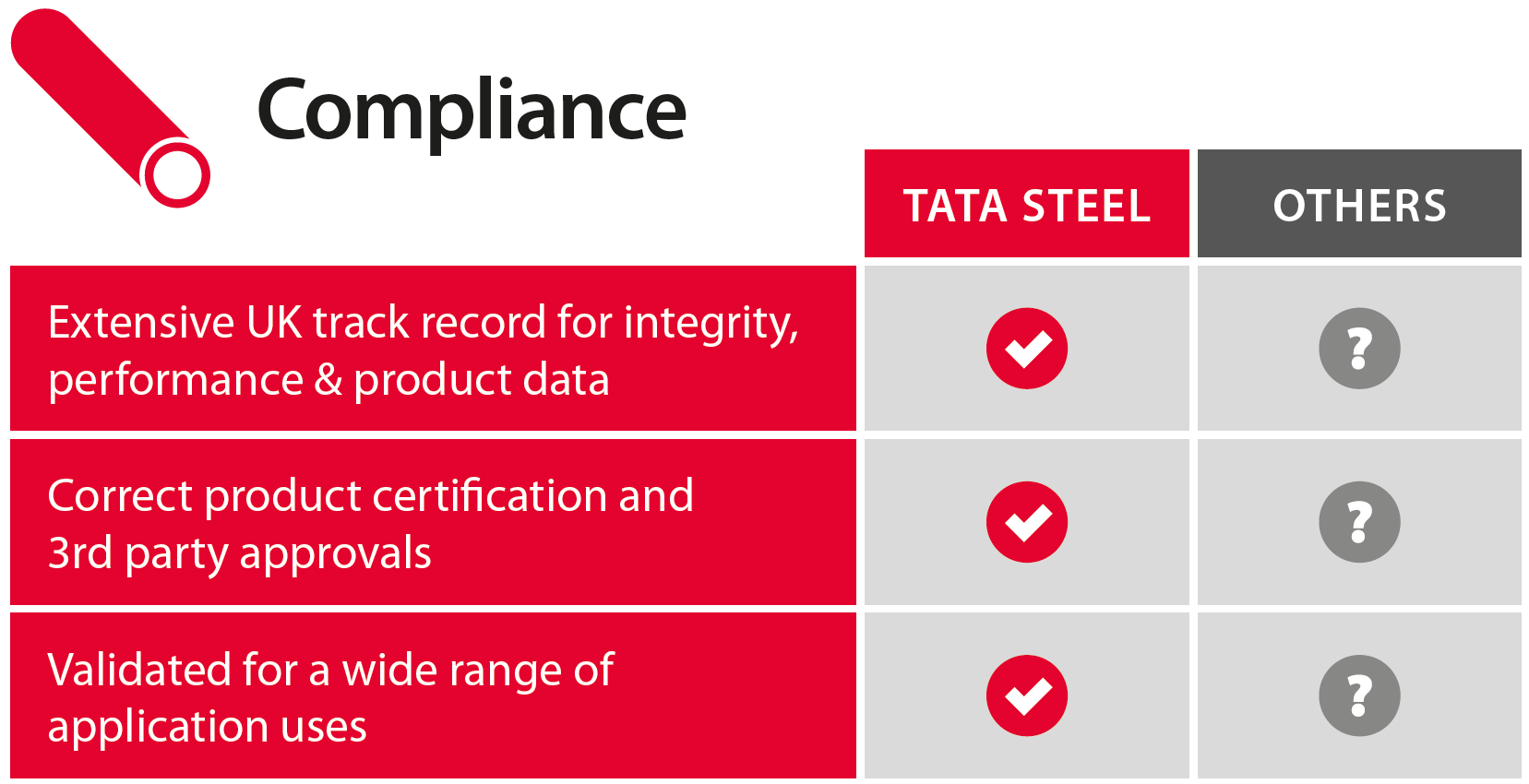

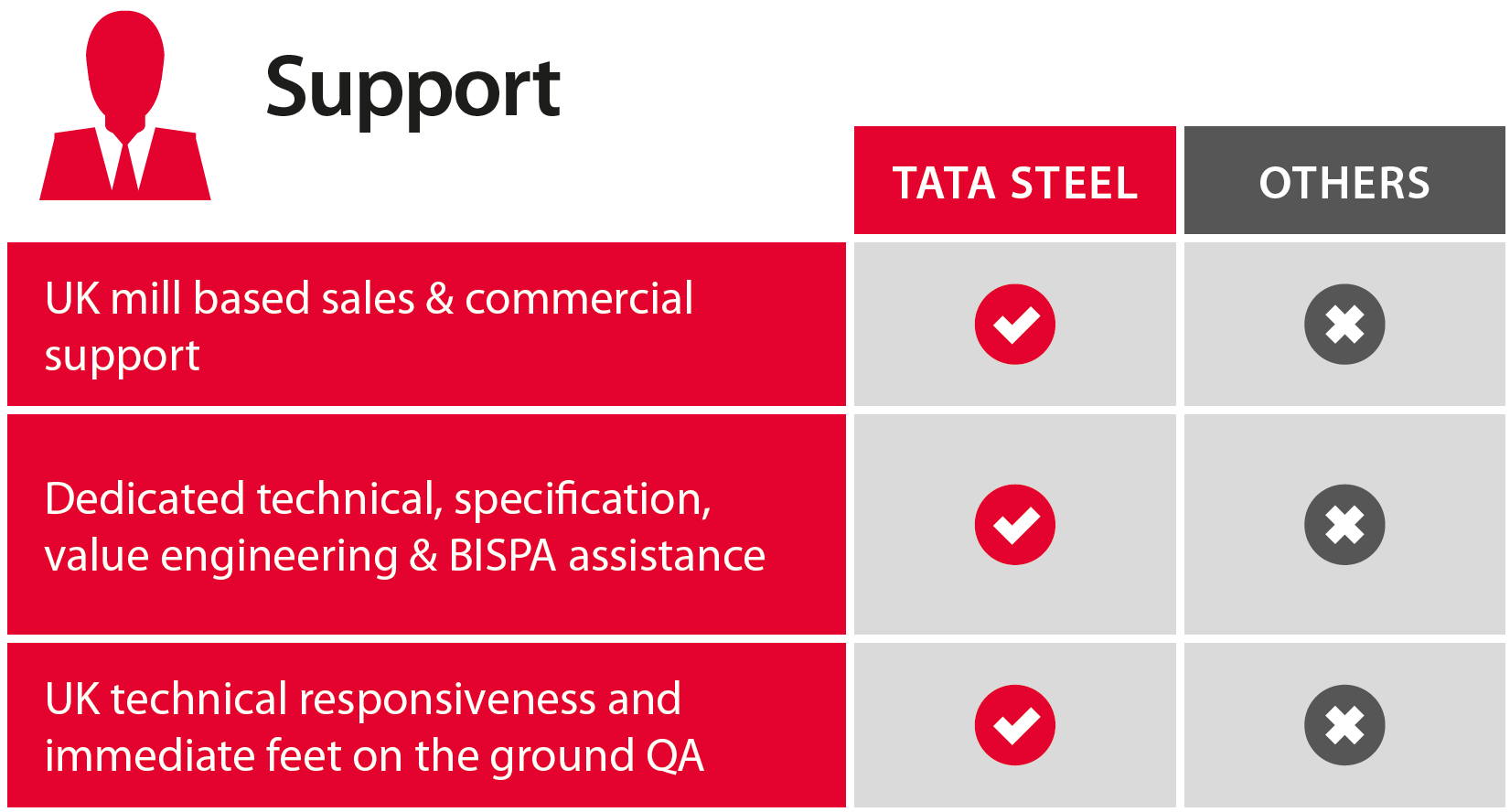

Our Part-2 tubes also provide a range of technical and sustainability features and benefits over competitor products, claiming to be the same.

Why specify Tata Steel UK

It is vital that good quality, compliant products are used within projects to reduce the risk of failure, approval or sign off issues.

Tata Steel UK stays ahead of the competition with our UK made tubes, with consistent performance and service life, extended warranties, technical support and sustainability benefits provided as standard.

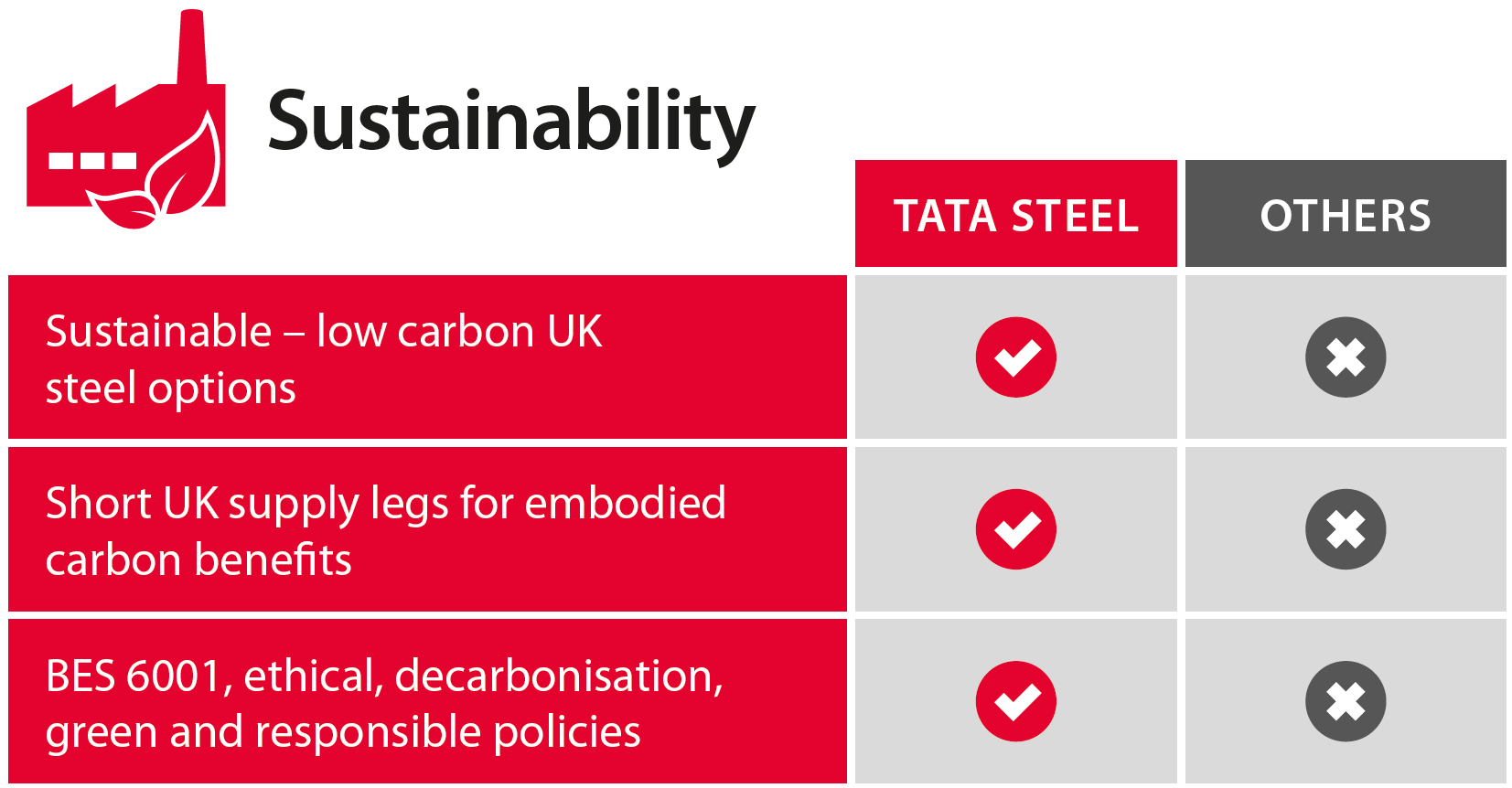

Sustainability focus

In today's construction sector, we regularly see specifiers and clients actively pushing to reduce the CO2 footprint of the materials used.

During the transition to our new UK low CO2 green steel processing capabilities, we now offer our new Eco tube product with 90% reduced CO2 compared to our standard carbon steel product offering.

This is achieved through our unique inset scheme, that offers CO2 reduction due to the actual validated activities and physical changes in our manufacturing processes, just ask about Install® Plus 235 Eco and Inline™ 265 Eco.

How to tell if it is UK made hot-finished

You can tell it is is our hot-finished tube by either the product description or marking, order acknowledgement, test certificate or any statements of conformity issued by Tata Steel UK.

Our conveyance tubes have all the information you need marked on the actual product confirming it’s hot-finished (GH = Get Hot) product.

In addition our CE (UKCA) mark confirms full product suitability for Fuel/Air/Gas (AVCP3) and water (AVCP4) use.

Check its Tata Steel UK, before you buy

For building and industrial services pipework, ensuring that tube is correctly specified and supplied is of paramount importance to ensure compliance, sustainability benefits and the satisfactory performance of the system over its lifetime.

Incorrectly defined tube specification may allow incorrect, commodity non-compliant cold-form or non-Tata Steel, non-UK made hot tubes getting into the supply chain. The risk significantly increases if parts of the project are subcontracted out without the correct controls in place.

By using a technically superior UK made, welded hot finished tube from Tata Steel, building and industrial service professionals can be assured of an unrivalled level of reliability and durability in use and compliance with all the latest relevant legislative, specification and sustainability requirements.

Not all tubes are the same, therefore, to ensure the success of your project, always specify UK made, welded hot-finished tube from Tata Steel.

Advantages of UK made welded hot-finished tubes

Our hot-finished tubes do not have a Heat Affected Zone (HAZ) as this is fully removed during the hot-manufacturing (normalising) process. This results in a superior product as it has:

- An ordered and consistent microstructure.

- No internal stress that can promote cracking.

- Consistent and reliable mechanical properties.

- Improved structural integrity and ductility.

- Improved and consistent toughness.

- Higher pressure integrity.

- Greater factor of safety.

- No loss of strength during additional welding or heating.

- Improved performance against corrosion.

- Ability to be bent to tight radii without splitting, creasing or collapsing.

UK made hot-finished tubes for a wide range of applications

Our products are well suited for many market uses, including:

| Building Services | Industrial | Data Centres |

| Tunnelling | Marine | Balance of Plant |

| District Heating | Conduit | Fire Defence |

Related downloads

Install® Plus and Inline™ Technical Mini Guide

Product Technical Submission document: Install® Plus 235

Product Technical Submission document: Inline™ 265

Complete Solutions brochure

Install® Plus 235 BIM Model

Inline™ 265 BIM Model